Molecular dynamics-based nanoscale diamond friction wear process simulation method

A molecular dynamics, nano-scale technology, applied in the field of nano-friction and wear, which can solve problems such as inapplicability and no consideration of temperature changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

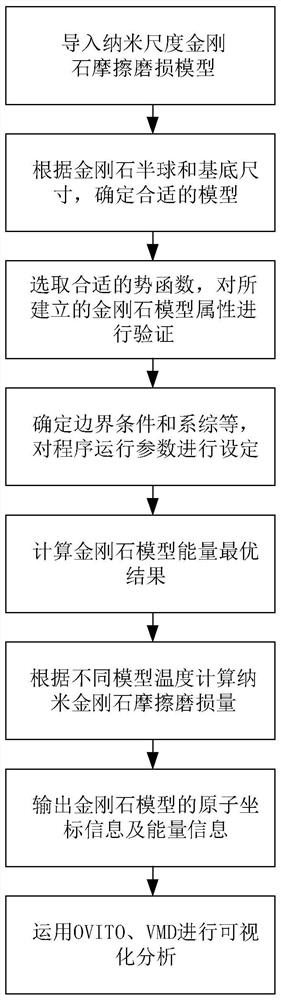

[0034] Such as figure 1 As shown, a nanoscale diamond friction and wear process simulation method based on molecular dynamics, including:

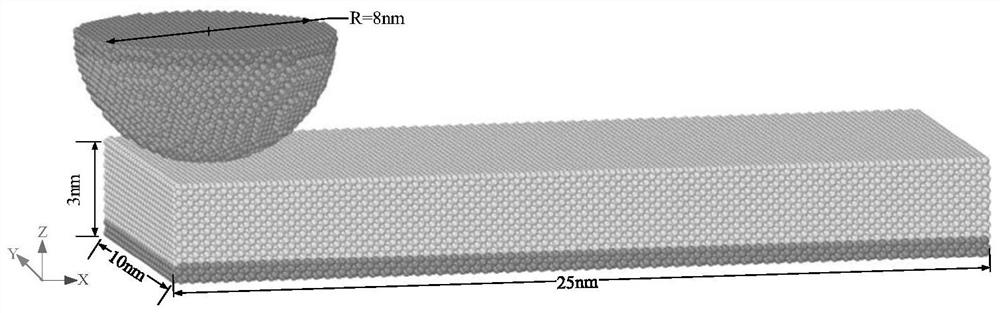

[0035] Step 1: Read the nanoscale diamond model data, such as figure 2 As shown, the diamond model is divided into two regions: the abrasive grain and the base part.

[0036] Step 2: Use the lattice command to fill the designated area with carbon atoms to form diamond.

[0037] Step 3: Determine the potential function that can describe the interaction force between atoms in the nanoscale diamond system;

[0038] The energy formula of the system described by the Tersoff potential function is:

[0039]

[0040] V ij =f C (r ij )[f R (r ij )+b ij f A (r ij )]

[0041] In the above formula, V ij Expressed as the potential energy between two particles, b ij Expressed as the strength of the bond between the two particles, r ij Indicates the distance between two particles, f C Used to represent the truncation function, f R is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com