Centrifugal ventilator disassembling tool with metal sponge aluminum shell

A metal sponge and ventilator technology, applied in the manufacture of tools, hand-held tools, etc., can solve problems such as extrusion scars, affecting product appearance quality, low hardness, etc., to avoid damage and failure, increase contact area, and improve decomposition quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

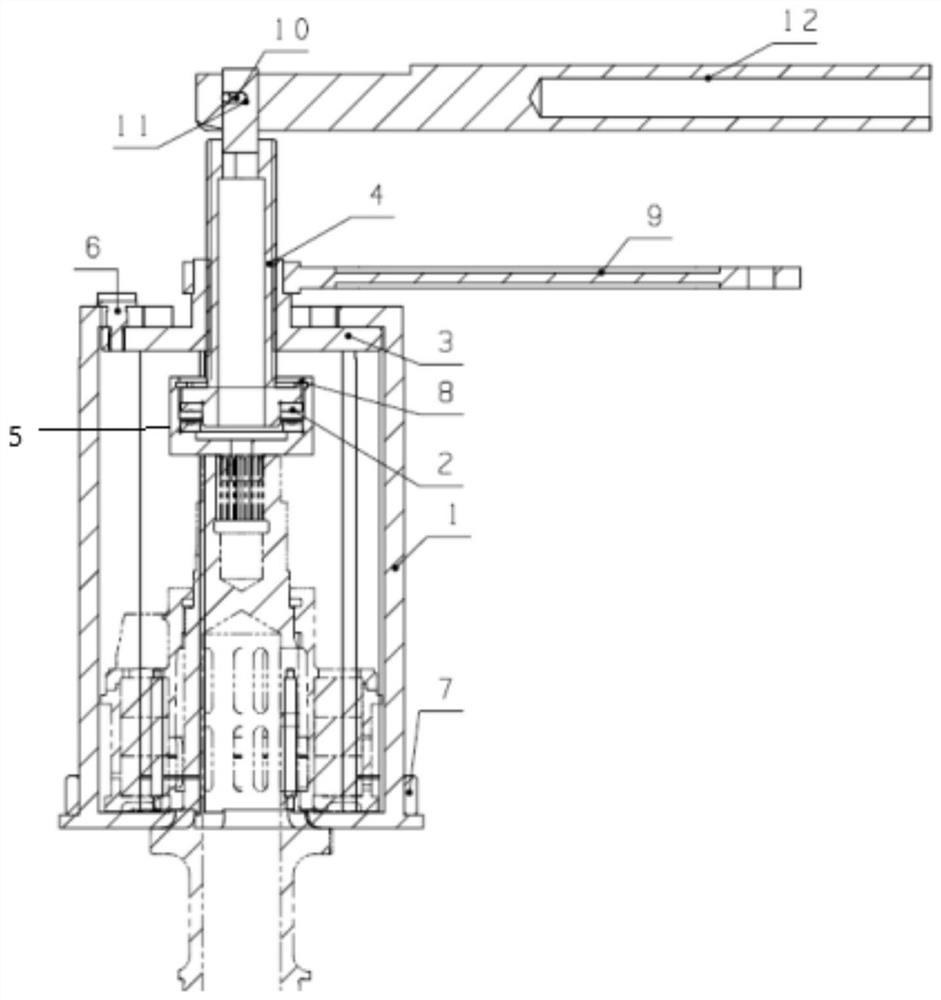

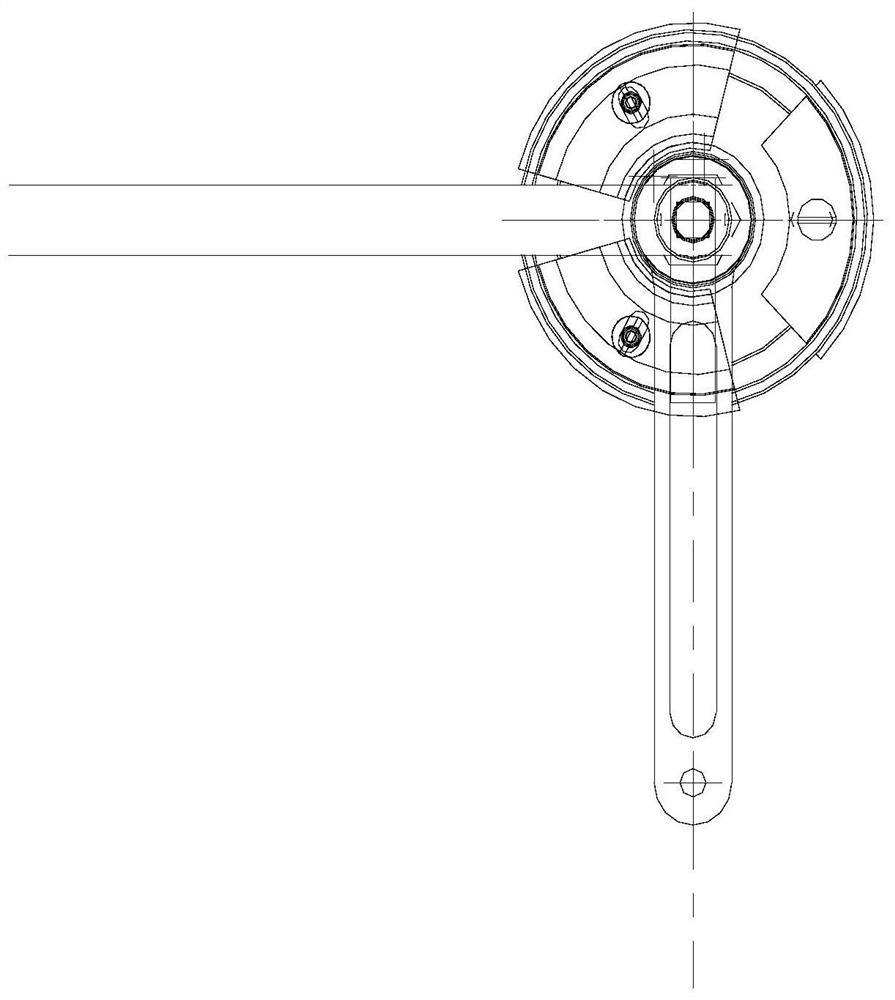

[0018] After research, the applicant found that: the existing centrifugal ventilator decomposition tool applies force for direct impact, the contact area between the tool and the shell is small, and the decomposition force is an impact force with uneven strength, which will be generated at the stressed place of the centrifugal ventilator shell. Different degrees of indentation will cause damage to the parts; at the same time, the disassembly tool has no centering function and cannot guarantee the coaxiality of the centrifugal fan and the gear shaft. The appearance of the parts is scratched, and the local force increases at the fittings, which may damage the parts and affect product quality and assembly efficiency.

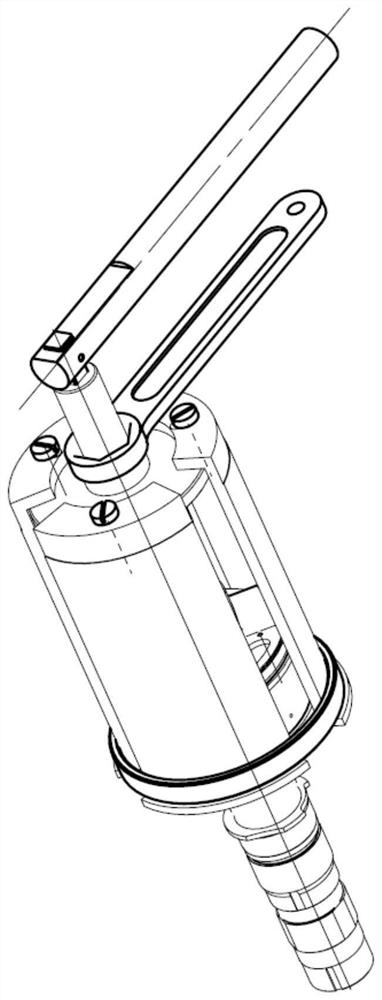

[0019] In order to solve the above problems, the present invention provides a centrifugal ventilator disassembly tool with a metal sponge aluminum shell. In one embodiment, the decomposition tool includes: a claw bracket, the claw bracket is a sleeve structure and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com