A puller for disassembling special-shaped deep groove ball bearings

A technology for deep groove ball bearings and bearings, applied in the field of disassembly of special-shaped deep groove ball bearings, can solve problems such as surface damage, waste, and bumping of parts, and achieve the goals of avoiding bumps, saving quality costs, and improving decomposition quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

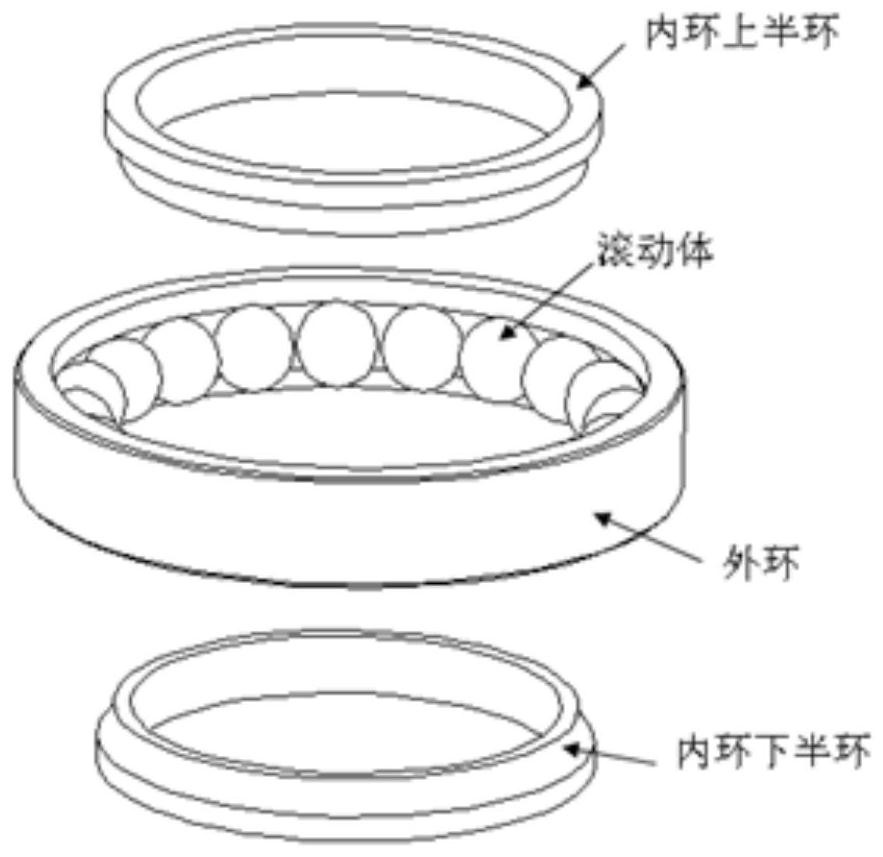

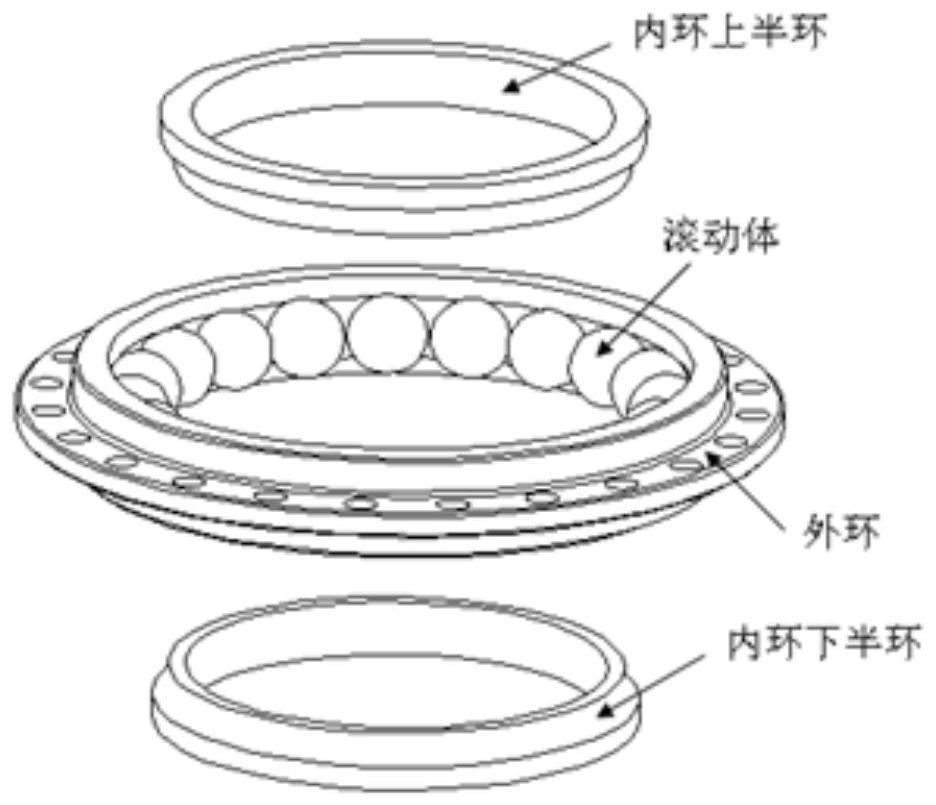

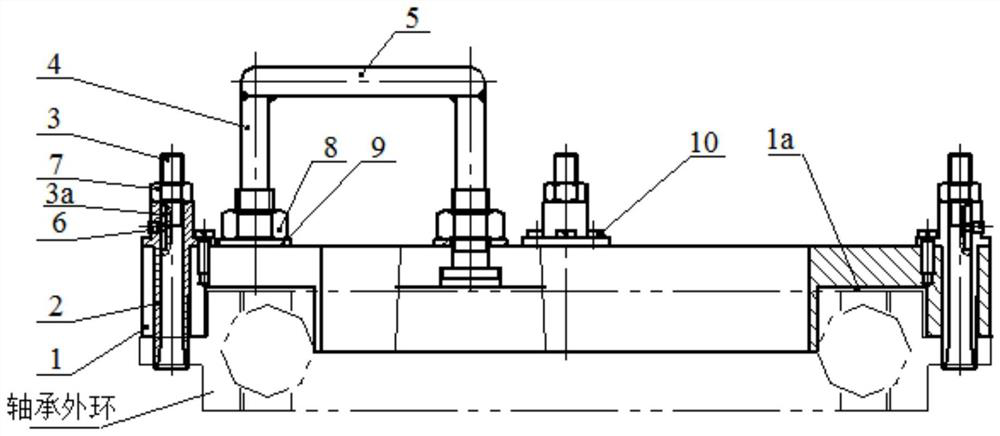

[0020] Such as Figure 1-4 As shown, a puller for disassembling a special-shaped deep groove ball bearing includes a base 1; the lower surface of the base 1 is provided with a ring groove 1a matching the upper surface of the outer ring of the bearing, which is used to locate the outer ring of the bearing. After the puller is installed, Ensure that the bearing rolling body does not move or fall; the edge of the base 1 is provided with a through hole corresponding to the process hole on the outer ring of the bearing, and a tensioning mechanism is provided in the through hole. The tensioning mechanism includes a clamp spring 2, a tensioning mechanism Rod 3, positioning piece 6 and nut 7, clamp spring 2 is fixed in the through hole through fastener 10 (screw), expansion rod 3 is arranged in clamp spring 2, and anti-rotation chute 3a is provided on the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com