Swing mechanism and shaving tool

A swing mechanism and drive mechanism technology, applied in metal processing, etc., can solve the problems of shortening the service life of the shaving tool, increasing the noise of the razor, affecting the shaving performance, etc., and improving the shaving performance And the use of safety, improve the use of comfort, reduce the effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

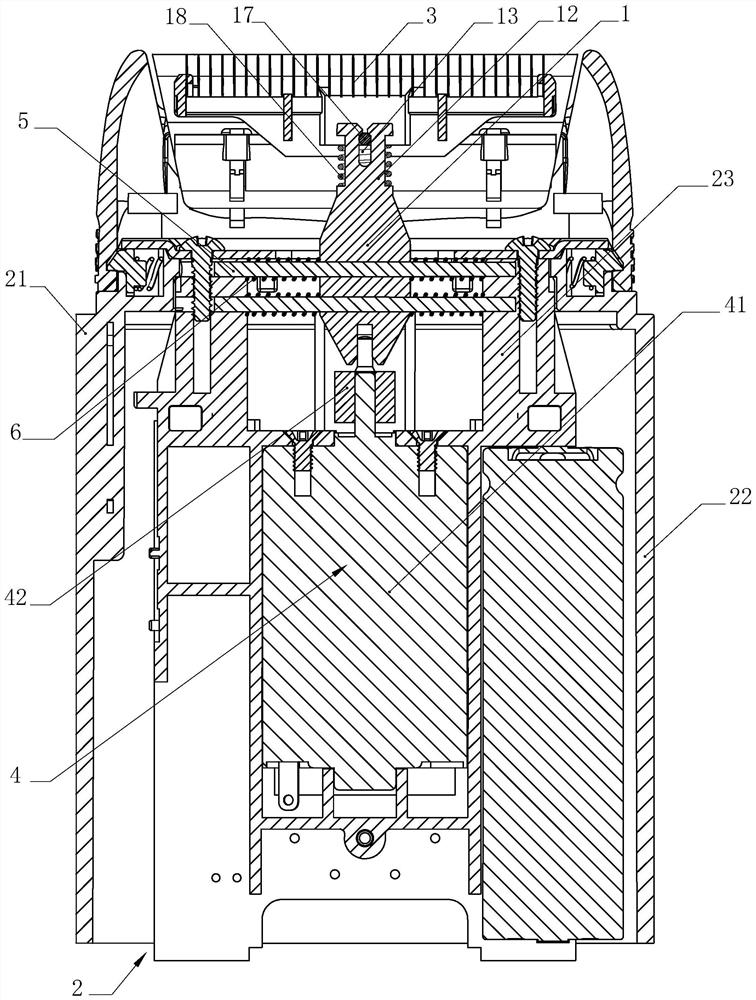

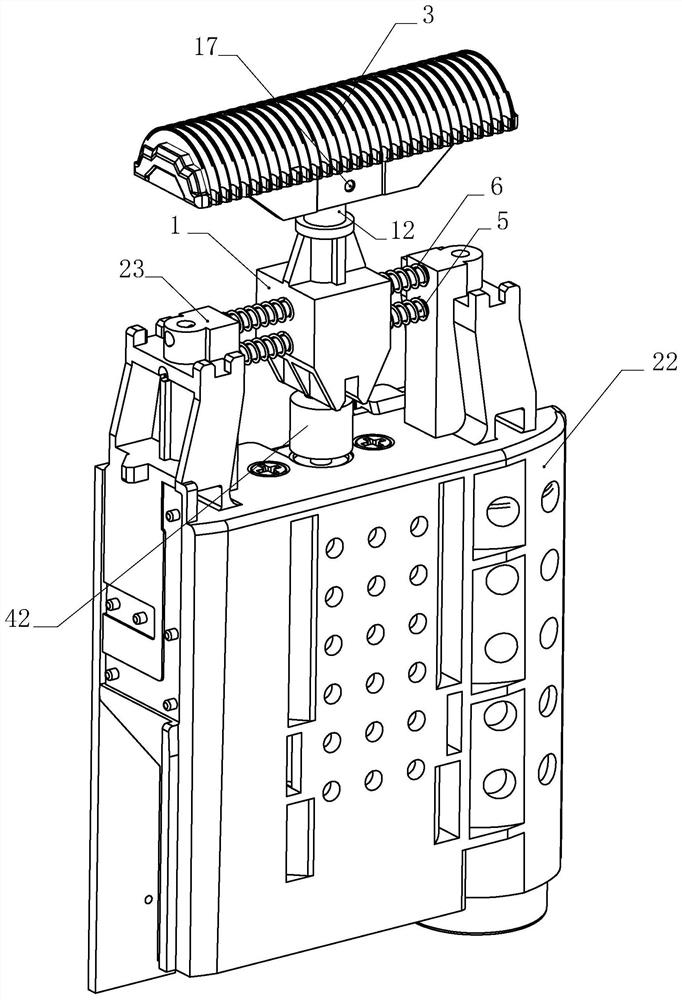

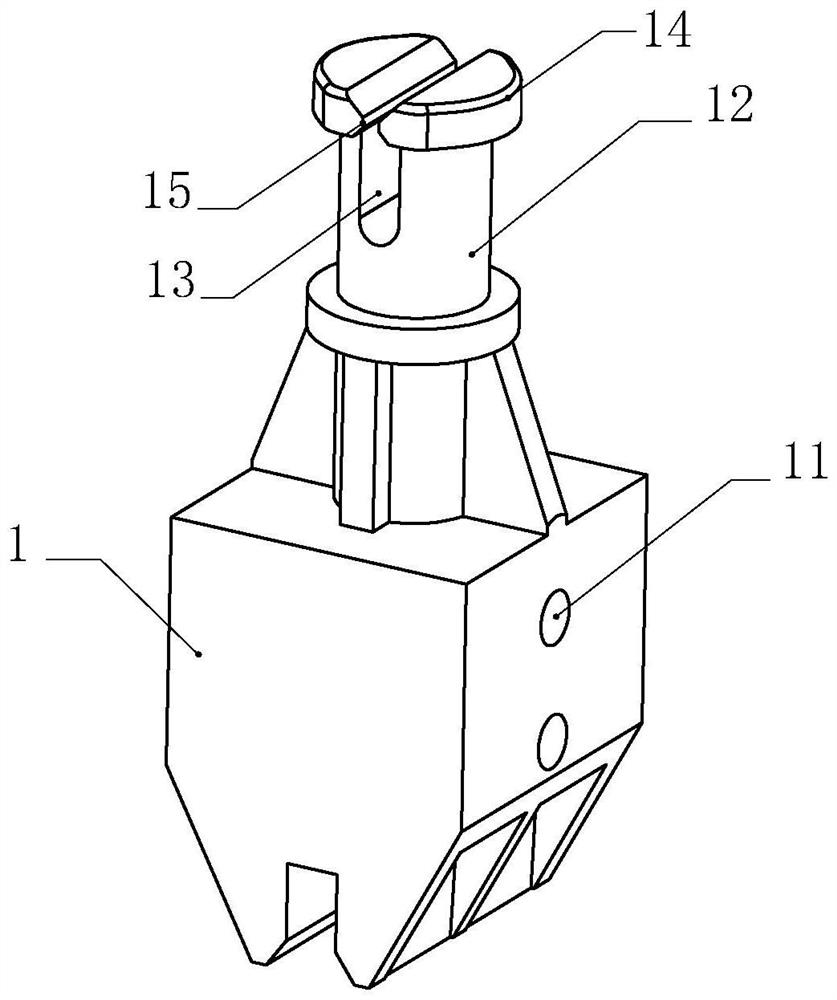

[0022] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

[0023] like Figure 1-4 As shown, the present invention is a swing mechanism, including a swing seat 1, the swing seat 1 is installed in the housing 2 and its upper end is connected with the movable knife 3, and its lower end is linked with the driving mechanism 4 installed in the housing 2 ; The housing 2 is provided with a limit mechanism 5, and the swing base 1 can move horizontally along the limit mechanism 5 under the drive of the drive mechanism 4 and is dynamically connected with the limit mechanism 5. By adding a limit mechanism 5 in the housing 2 and dynamically connecting the swing seat 1 to the limit mechanism 5, when the drive mechanism 4 starts, it can drive the swing seat 1 to move horizontally along the limit mechanism 5, avoiding the When the driving mechanism 4 is started, the swing seat 1 twists or moves, preventing the blade of the moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com