Zero-gravity small crane

A zero-gravity, hoisting technology, applied in the direction of cranes, clockwork mechanisms, load hanging components, etc., can solve the problems of wasting manpower, complicated operation, and self-heavy, and achieve the effect of easy storage and easy rotation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

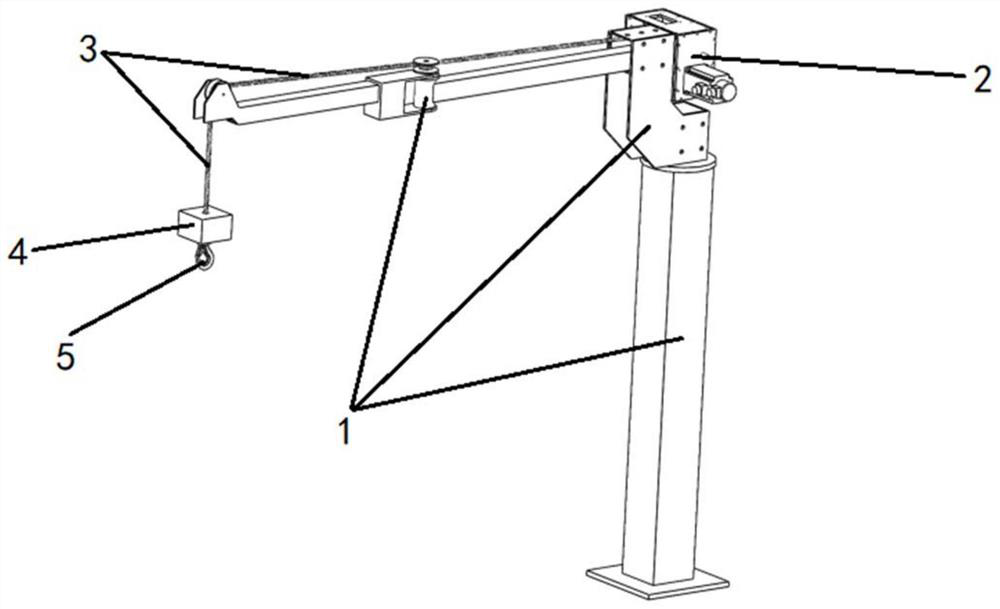

[0051] like figure 1 As shown, a zero-gravity small crane includes a bracket 1, and the bracket 1 includes a large cantilever 11 and a small cantilever 12, and both the large cantilever 11 and the small cantilever 12 can be rotated; the present invention adopts two sets of rotatable cantilevers, the maximum The use of space is equivalent to adjusting the length of the overall cantilever to adapt to hoisting at different distances; it can be folded when not in use for easy storage.

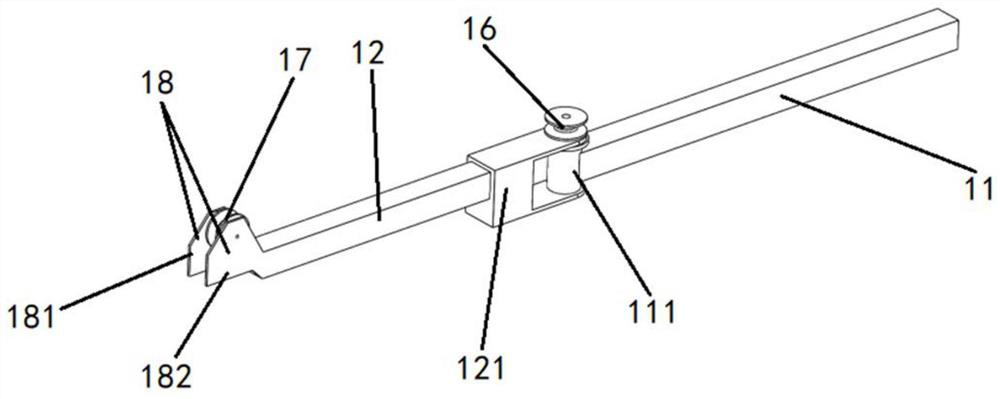

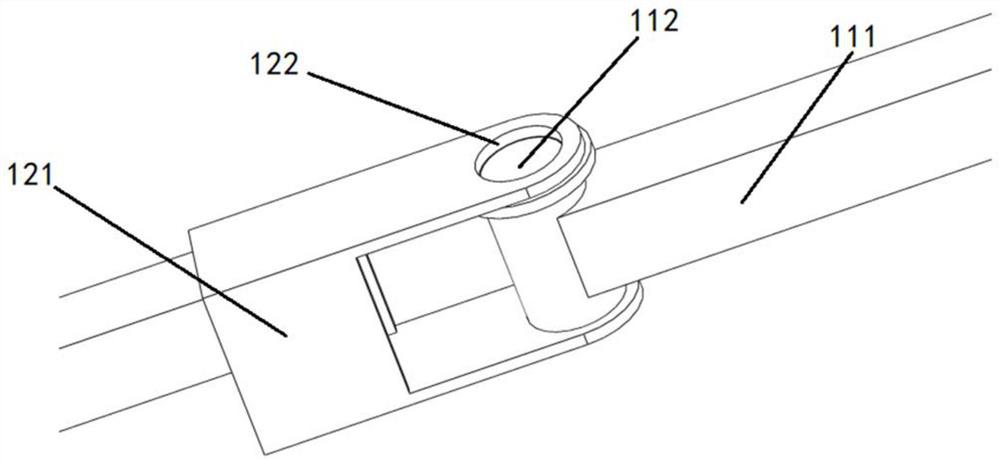

[0052] like Figure 2-3 As shown, in this embodiment, one end of the large cantilever 11 is connected to one end of the small cantilever 12; the large cantilever 11 and the small cantilever 12 are connected by a connecting shaft, and the small cantilever 12 takes the connecting shaft as the rotation point for horizontal rotation Rotation; a first connection part 121 is provided at the end of the small cantilever 12 close to the large cantilever 11, and a second connection part 111 corresponding to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com