Particulate matter filtering efficiency testing device and using method thereof

A technology for filtration efficiency and testing device, which can be used in measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

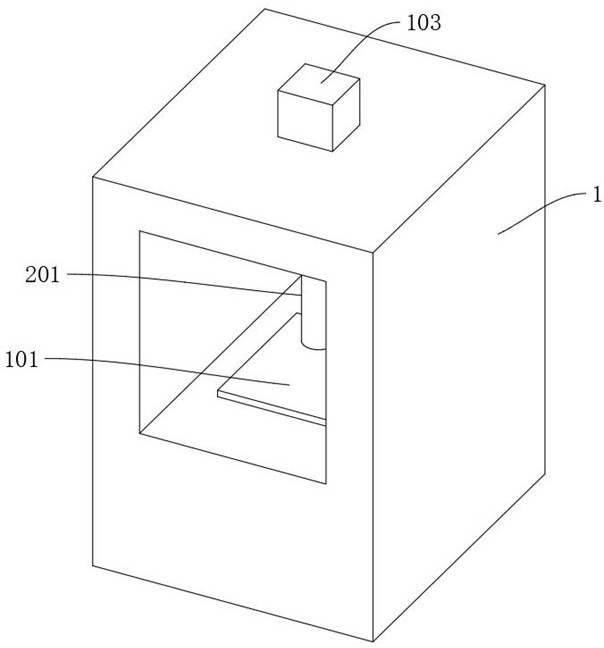

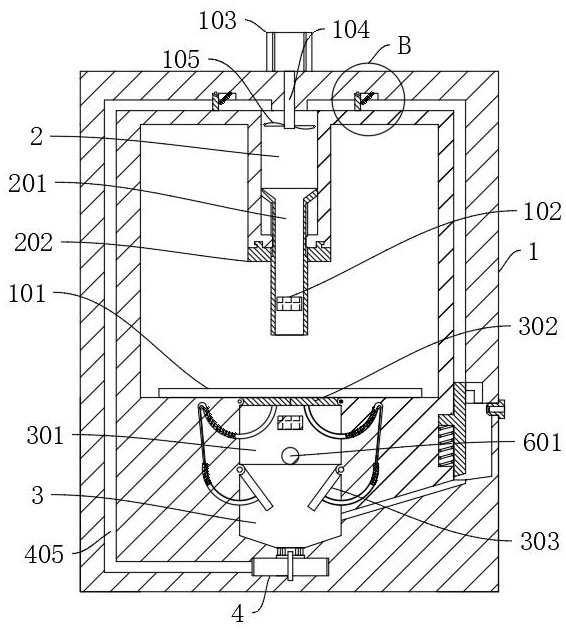

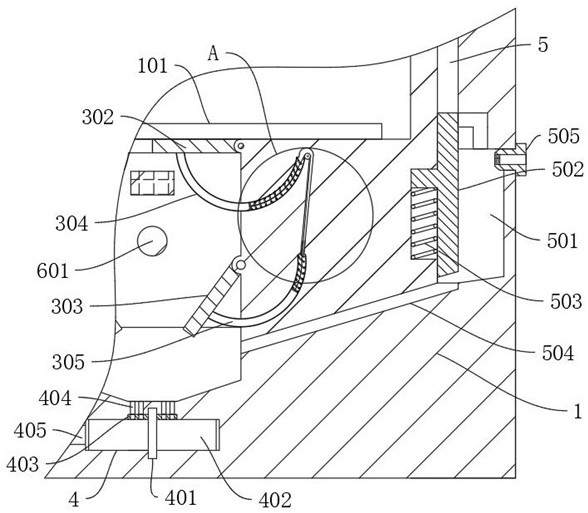

[0044] refer to Figure 1-8 , a particle filtration efficiency testing device, comprising a concentration detection component 102 for measuring dust concentration, a detection body 1, a filter screen 101 to be tested, the filter screen 101 to be tested is placed in the detection body 1, and also includes: a driving motor 103, Connected to the upper end of the detection body 1 to provide power for the device; the sliding cylinder 2 is fixedly connected to the upper end of the detection body 1; the sealing cylinder 201 is slidably connected in the sliding cylinder 2, and the concentration detection component 102 is connected in the sealing cylinder 201 ; The rotating shaft 104 is fixedly connected to the output end of the drive motor 103, and is partly in the sliding cylinder 2; the first rotating fan blade 105 is fixedly connected to the rotating shaft 104 for making the gas flow; the storage chamber 3 is arranged on The bottom end of the detection body 1 is used to store dust ...

Embodiment 2

[0053] refer to figure 2 , Figure 4 , Figure 8 , a particle filter efficiency testing device, which is basically the same as that of Embodiment 1, furthermore: the bottom end of the sliding cylinder 2 is rotatably connected with a first rotating block 202, the sealing cylinder 201 is threadedly connected with the first rotating block 202, and the sealing cylinder 201 A guide groove 203 is arranged on the top, and a guide block 204 matching the guide groove 203 is fixedly connected to the sliding cylinder 2 to facilitate the movement of the sealing cylinder 201 .

Embodiment 3

[0055] refer to Figure 2-4 , a particle filtration efficiency testing device, which is basically the same as that of Embodiment 1, furthermore: the upper end of the storage chamber 3 is connected with a first rotating plate 302 for symmetrical rotation, and the middle of the storage chamber 3 is connected with a second rotating plate 303 for symmetrical rotation. A collecting cavity 301 is formed between the second rotating plate 303 and the first rotating plate 302, and a concentration detection component 102 is connected to both sides of the upper end of the collecting cavity 301, which is convenient for detecting the dust concentration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com