Spinning production line control system

A control system and production line technology, applied in the textile field, can solve problems such as complicated situations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

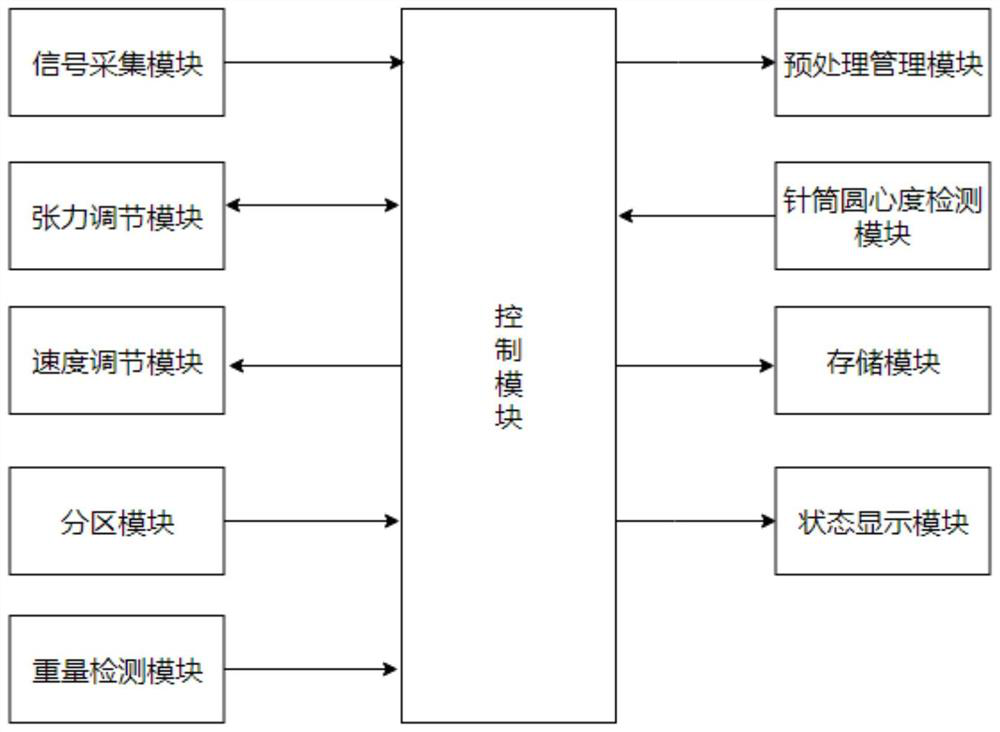

[0026] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0027] Stripes with inconsistent color and luster appear on the gray fabric of natural color or after dyeing and finishing. The rungs of circular woven fabrics are mostly regular bars. Abnormally, cloth-faced bars are composed of one or more yarns. There will be certain differences between the yarn at the crosspiece and the yarn at the normal cloth surface in terms of color difference, thickness, composition, twist, hairiness, coil, density, and stretch yarn tension. The factors that form the rungs of circular woven fabrics are caused by the yarn, the circular knitting machine, and the dyeing and finishing.

[0028] Circular machine fabric rungs appear, which are caused by wrong manufacturer, wrong type, raw material receiving batch fluct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com