Repairable iron tower anti-icing disaster reduction design method

A design method and tower technology, applied in special data processing applications, geometric CAD, etc., can solve problems such as foundation damage, scrapping of the original tower, collapse of the entire tower, etc., to avoid deformation damage, easy to repair, easy to replace.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

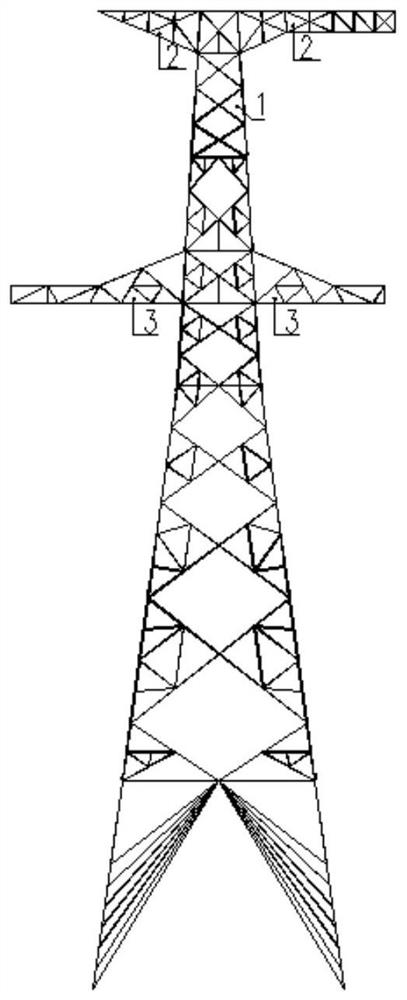

[0035] The tower body 1 is composed of angle steel components, and forms a complete iron tower with the ground wire bracket and the wire cross arm; the iron tower body is the main part of the iron tower. If the tower body is damaged, it is difficult to repair and a new tower needs to be reassembled.

[0036] The ground wire support 2 is composed of angle steel components, which are divided into main material, inclined material and auxiliary material, and is connected to the tower body through bolts and gusset plates; the ground wire of the power transmission circuit is connected to the ground wire support, and the ground wire is connected to the Load transfer and tower body.

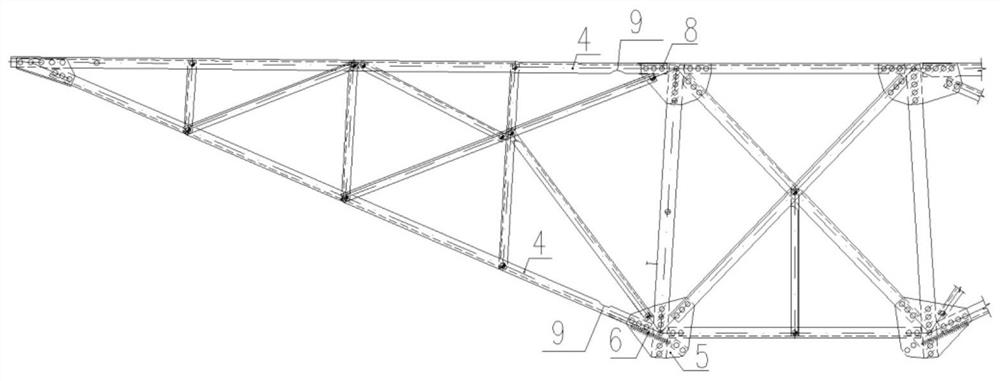

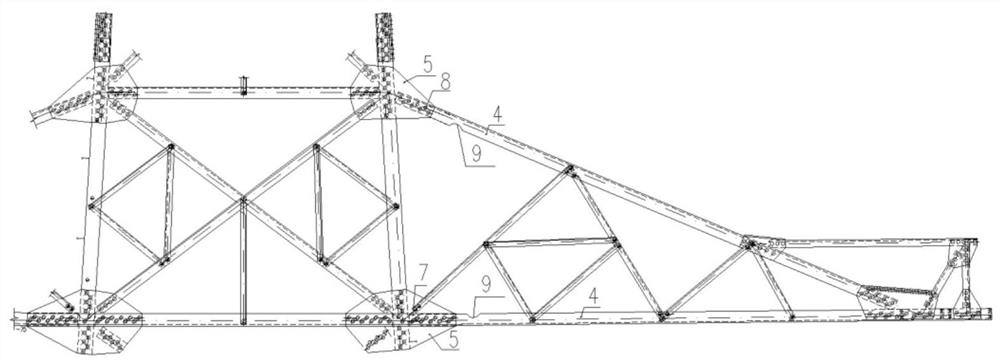

[0037] The conductor cross arm 3 is composed of angle steel components, which are divided into main material, inclined material and auxiliary material, and are connected to the tower body through bolts and gusset plates. The wires of the transmission circuit are connected to the wire cross arm, and the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com