Reliable detection of container crane and harness

A container crane, container technology, applied in the direction of crane, trolley crane, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

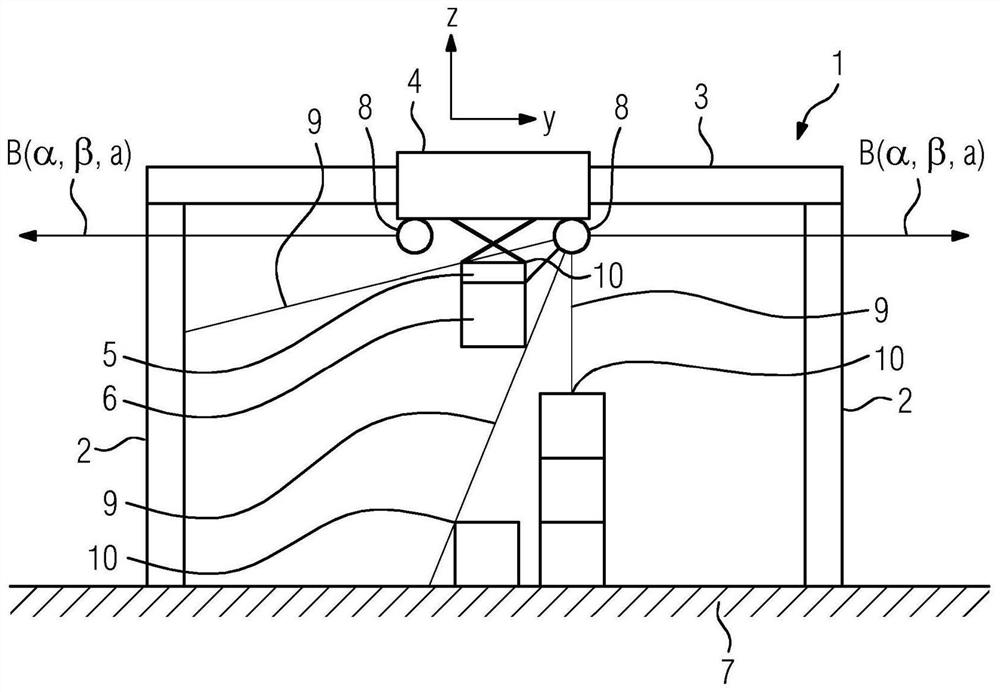

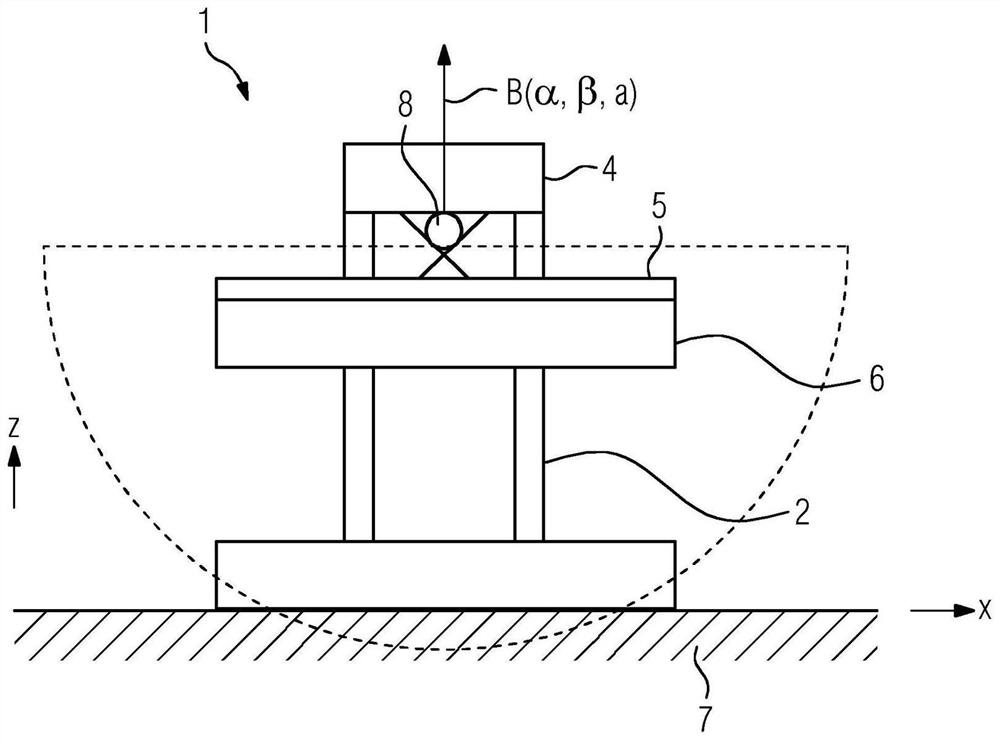

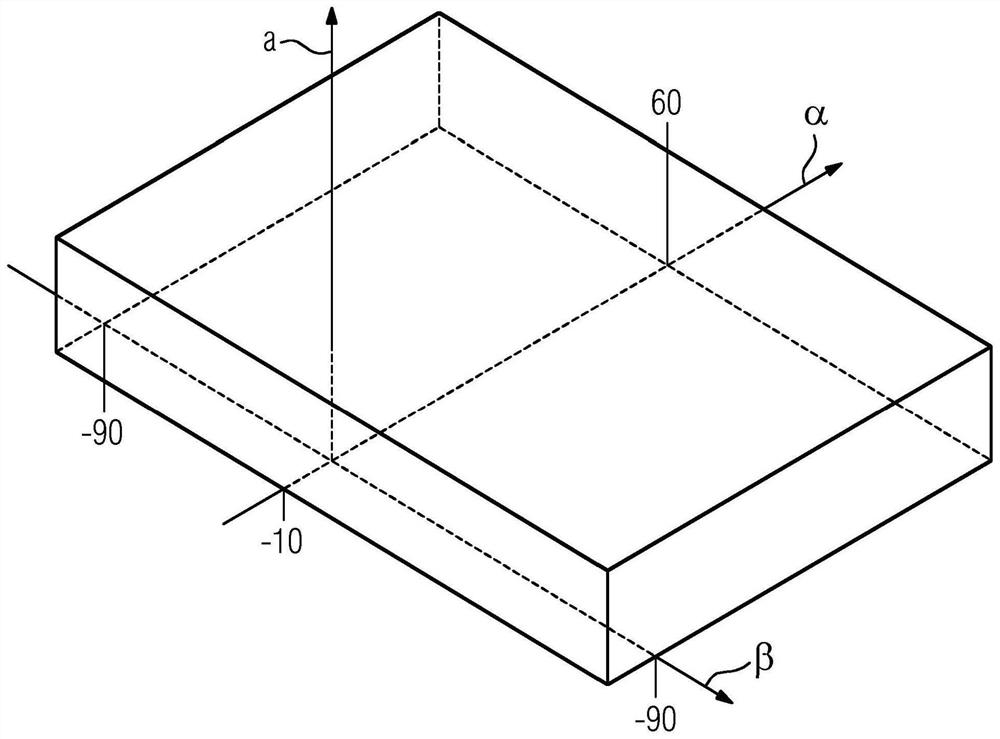

[0044] according to figure 1 with figure 2 , The container crane has a mast 1 . The portal frame 1 has two supports 2 which are connected to each other via crossbeams 3 . Container cranes can be configured as container gantry or other gantry cranes. The support 1 is travelable in the travel direction x of the container crane. Direction x is referred to below as crane direction x, since the container crane travels as a whole in this x direction. The tackle 4 of the container crane can travel on the beam 3 . The direction along which the trolley 4 can travel is hereinafter referred to as the trolley direction and is provided with the reference symbol y. The block direction y is orthogonal to the crane direction x. Both the crane direction x and the trolley direction y are generally oriented horizontally.

[0045]The rigging 5 is arranged at the tackle 4 . The rigging 5 is used to lift and lower the container 6 . The rigging 5 can include, in particular, so-called sprea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com