Harmful gas filtering equipment for chemical pharmacy

A technology of harmful gas and filtering equipment, which is applied in the direction of dispersed particle filtration, chemical instruments and methods, and dispersed particle separation. Improves jetting ability and slows down the effects of over-squeezing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

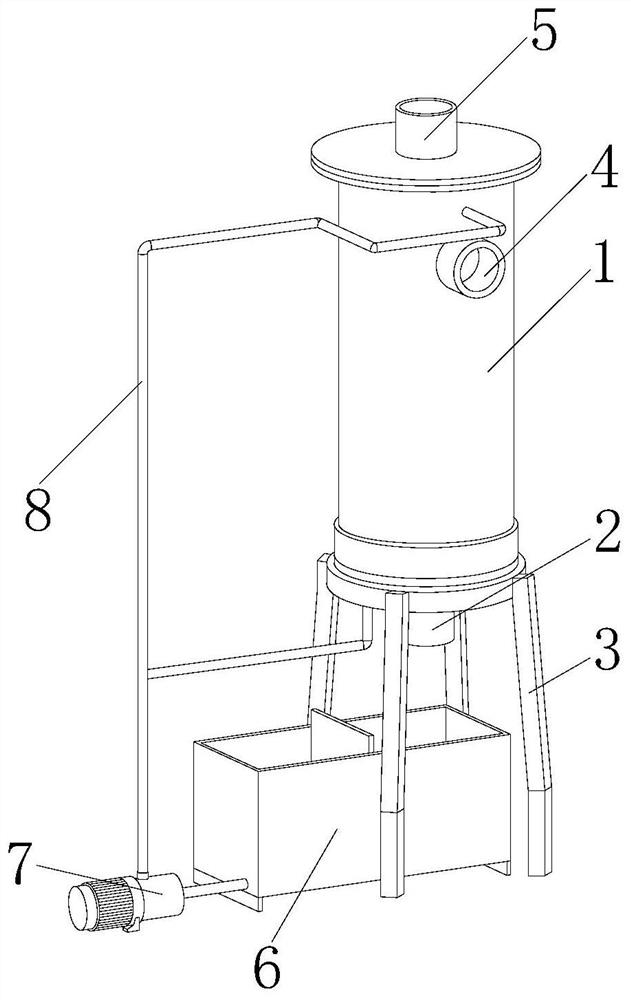

[0022] as attached figure 1 to attach Figure 4 Shown:

[0023] The present invention is a kind of harmful gas filter equipment for chemical industry and pharmacy, its structure comprises filter device 1, water outlet pipe 2, support foot 3, air outlet pipe 4, air inlet pipe 5, water tank 6, water pump 7, circulating water pipe 8, described filter device 1 The lower end is embedded with a water outlet pipe 2 and communicates with each other. The lower end of the filter device 1 is welded with a support foot 3. The outer upper end of the outlet pipe 4 is embedded with an outlet pipe 4 and communicated with each other. The air inlet pipe 5 is embedded and installed. On the top of the filter device 1, the water tank 6 is located at the bottom of the filter device 1, and the left end of the water tank 6 is provided with a water pump 7, the water pump 7 communicates with the lower end of the circulating water pipe 8, and the upper end of the circulating water pipe 8 is embedded an...

Embodiment 2

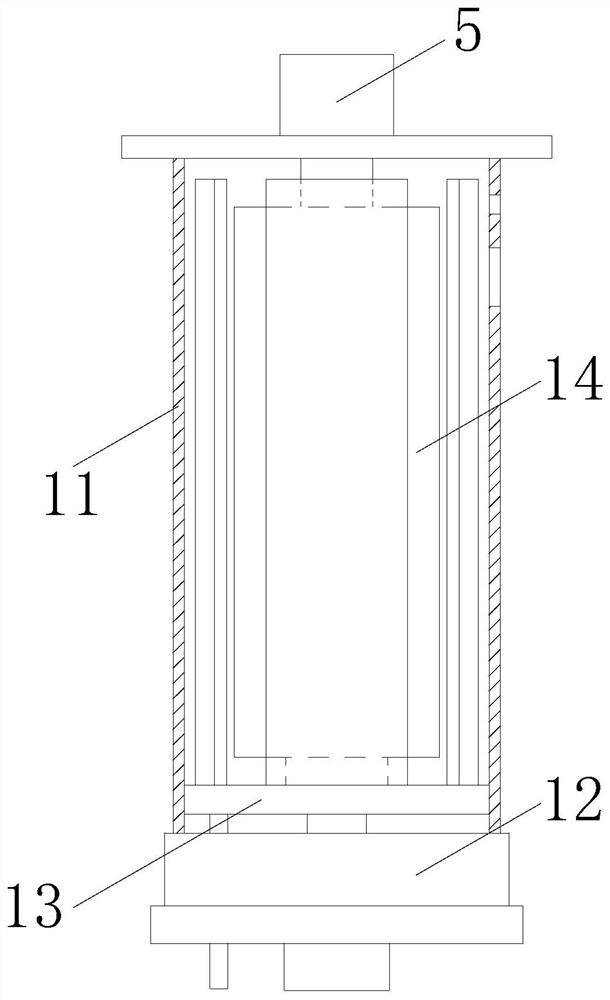

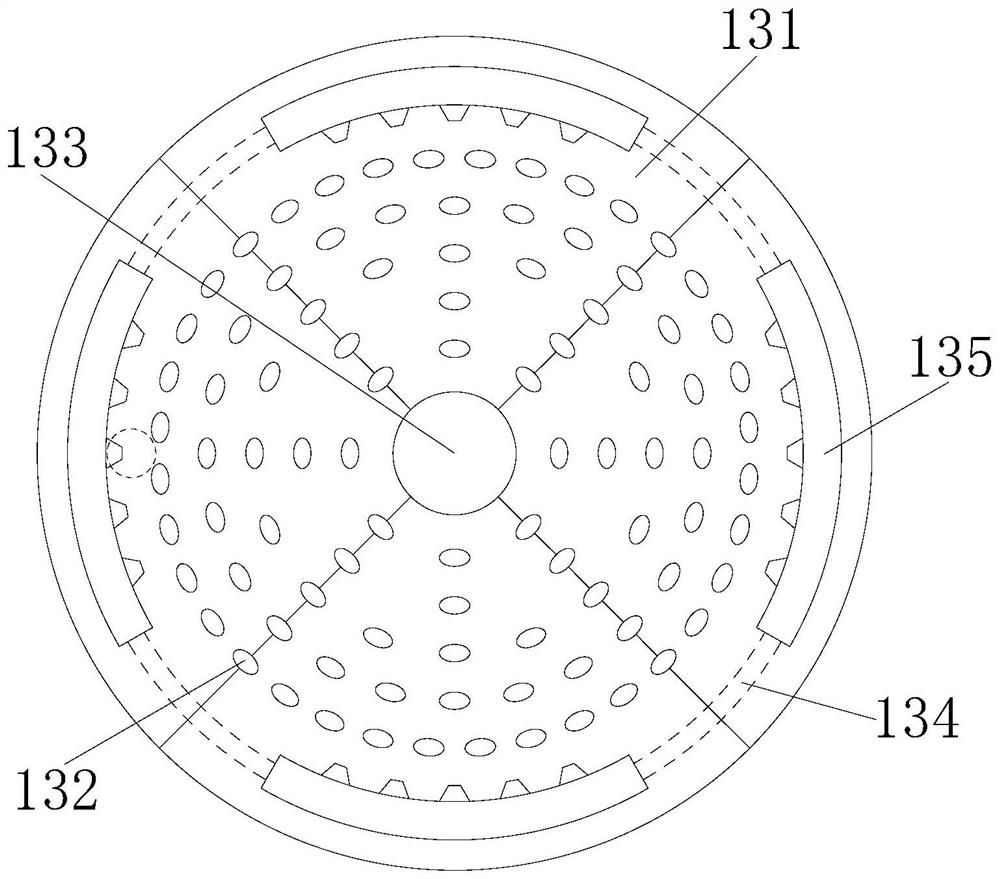

[0029] as attached Figure 5 to attach Figure 7 Shown:

[0030] Wherein, the filter element device 14 includes a multilayer filter element 141, an air inlet 142, a dispersion mechanism 143, and a uniform air outlet mechanism 144, and the lower end of the multilayer filter element 141 is installed on the upper surface of the lower end of the even air outlet mechanism 144. The lower end communicates with the upper end of the dispersing mechanism 143, the dispersing mechanism 143 is located at the inner upper end of the multi-layer filter element 141, and the bottom of the uniform air outlet mechanism 144 is slidably installed in the inner center of the sealing base 12 to ensure that the even air outlet mechanism 144 can drive the multi-layer filter element 141 Carry out fixed-point smooth rotation in the process of flushing.

[0031] Wherein, the dispersing mechanism 143 includes a sealing tube 43a, a multi-port tube 43b, a connecting rod 43c, a push ring 43d, and an air guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com