Automatic punching machine for sugarcane knife handle

A punching machine and handle technology, applied in metal processing, fixed drilling machines, etc., can solve the problems of multiple processes, dangerous working environment, time-consuming, etc., and achieve the effects of improving work efficiency, accurate and stable feeding process, and reducing the risk factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

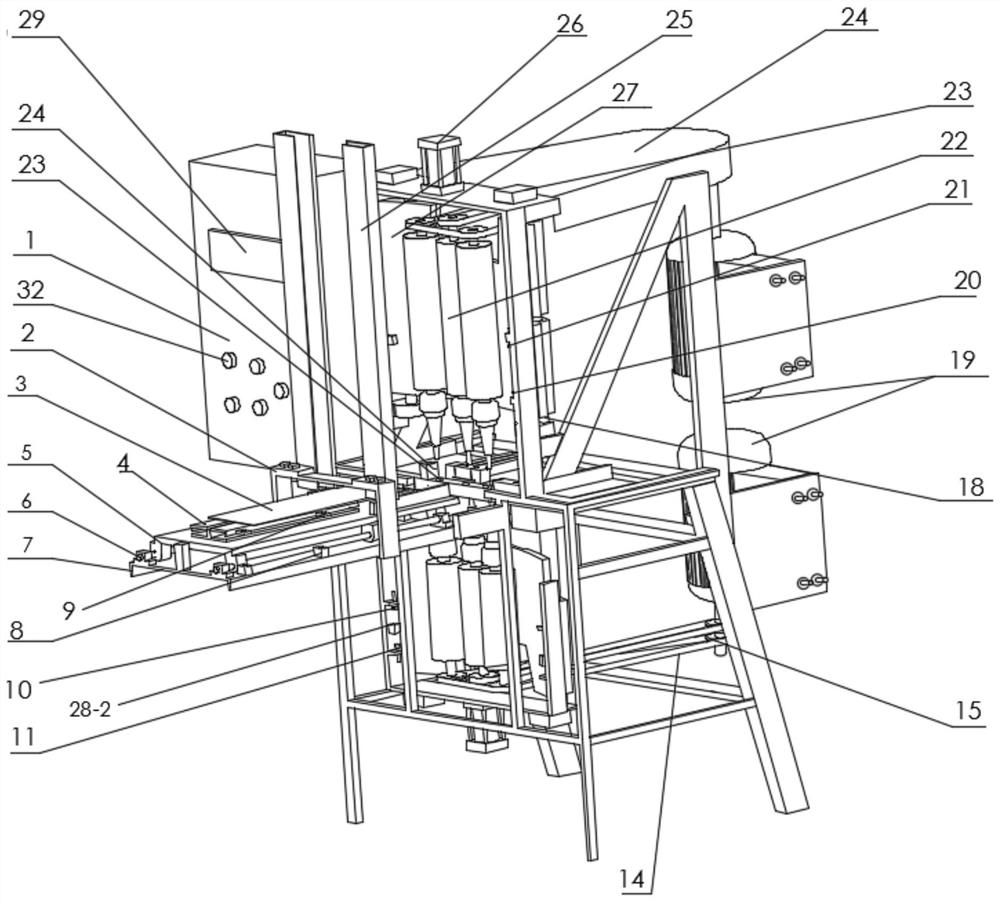

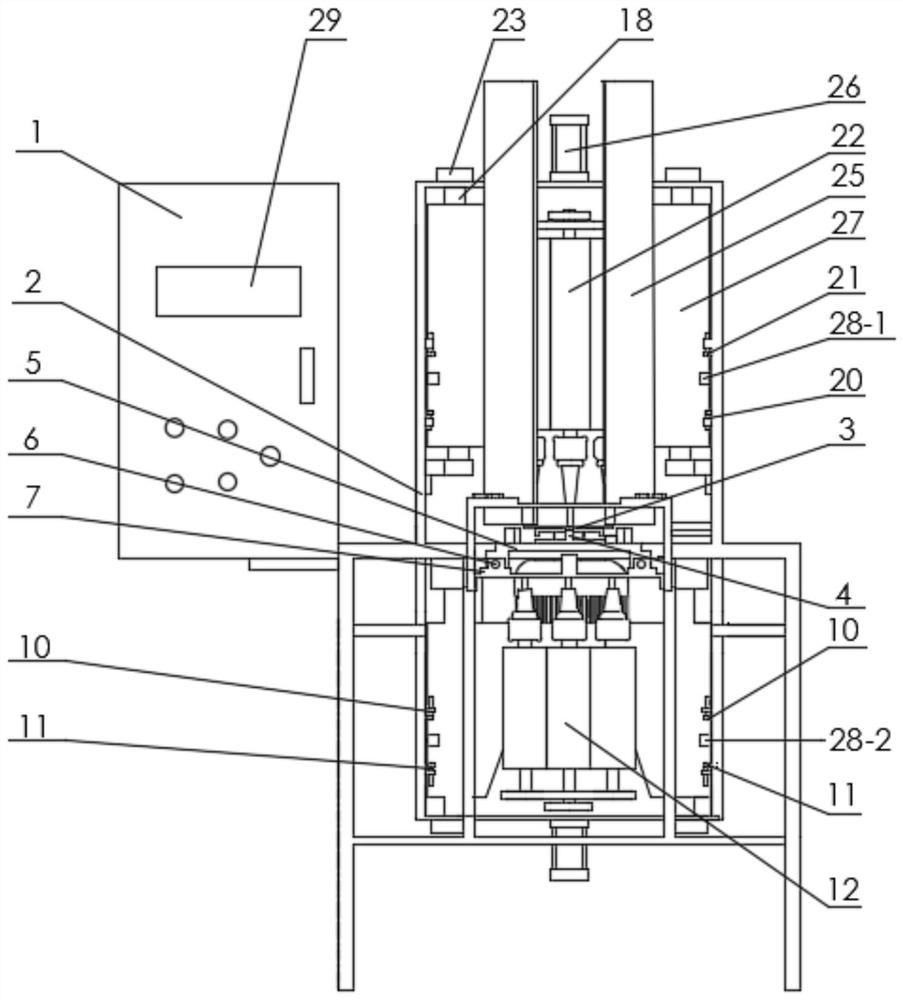

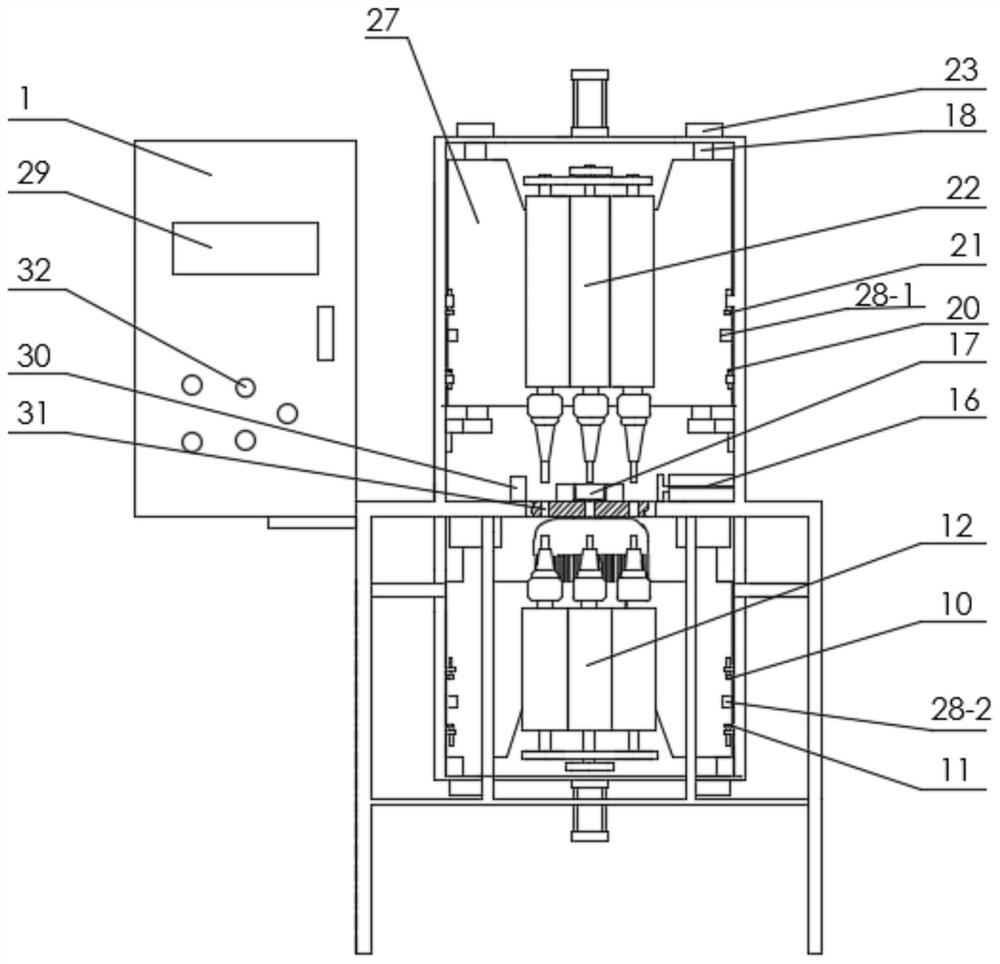

[0034] The technical solutions of the present invention will be further described below through specific examples.

[0035] like Figure 1-Figure 5 The shown sugarcane knife handle automatic punching machine includes a control box 1, a feeding device, a height-adjustable punching device and a positioning clamping device. The hole device is connected to the positioning clamping device respectively, the feeding device is provided on one side of the height-adjustable punching device, and the positioning clamping device is provided below the height-adjustable punching device. device, an outlet is provided between the feeding device and the positioning and clamping device; the control box 1 is provided with a button 32 and a touch screen 29 .

[0036] Described feeding device comprises frame, pushing device, discharge rack 25, the first slide rail 6, slide rail fixed mount 7 and push baffle plate 13, the top of described frame is provided with slide rail fixed mount 7, slide rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com