Ballastless track assembly for longitudinal and transverse beam system steel bridge, construction device and technology

A technology of ballastless track and crossbeam, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems of reducing the reliability of the system in service, the force of the anti-loosening structure is not applicable, and the threat to the safe operation of the train, so as to achieve a compact structure, Low cost, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

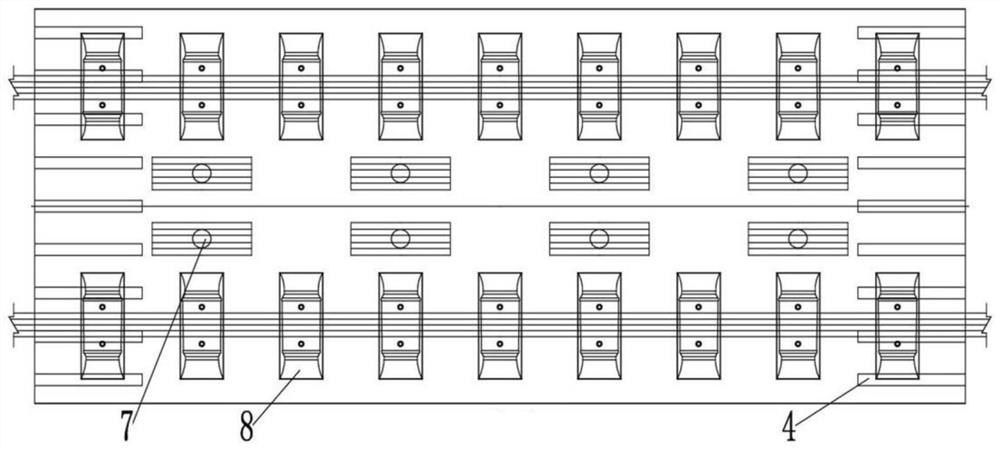

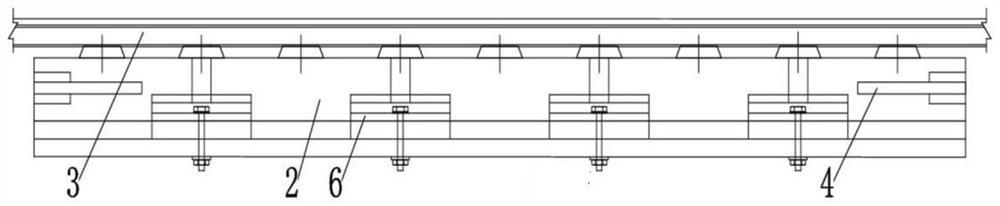

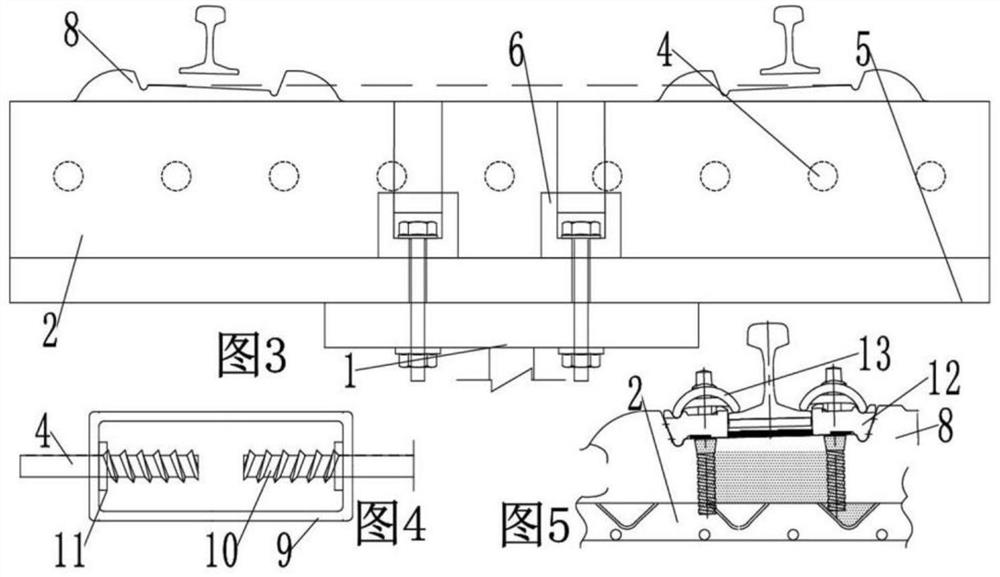

[0138] Example 2, such as Figure 1-16 ,like figure 1 As shown, the ballastless track assembly for the longitudinal and horizontal beam system steel bridge of the present embodiment includes a track plate 2 for being arranged on the steel beam 1;

[0139] On track plate 2, be provided with support rail platform 8, be provided with steel rail 3 by fastener on track support platform 8; Be provided with tension rod 4 on track plate 2 longitudinal end faces,

[0140] A connection assembly 9 is arranged between the tension rods 4 of the longitudinally adjacent track plates 2;

[0141] The threaded section 10 of the tension rod 4 enters the connection assembly 9 and is fastened by the connection nut 11;

[0142] A chute 6 is longitudinally arranged in the track plate 2, and a mounting hole 7 is vertically arranged on the chute 6; the flange of the track plate 2 and the steel beam 1 is fastened and connected by bolts in the mounting hole 7;

[0143] The anchoring reinforcement of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com