Front middle door lock of automobile

A technology for door locks and automobiles, used in vehicle locks, electric locks, building locks, etc., can solve the problems of high risk of failure of parts motion transmission, increase the complexity of mechanical motion, and inability to open the lock body, so as to reduce the space of the lock body. The effect of layout and transmission is fast and labor-saving, and the risk of failure is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

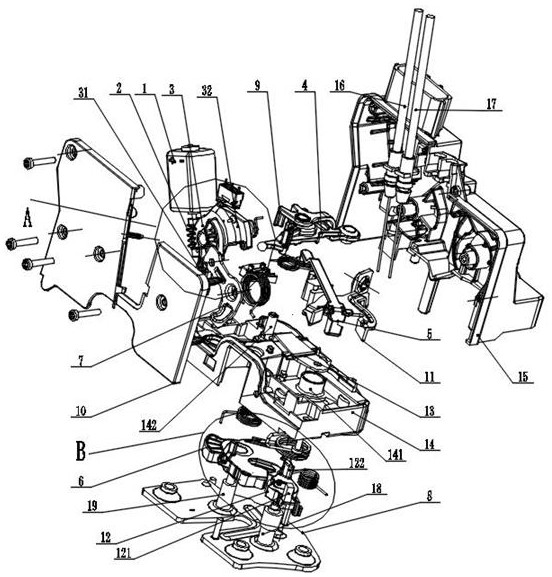

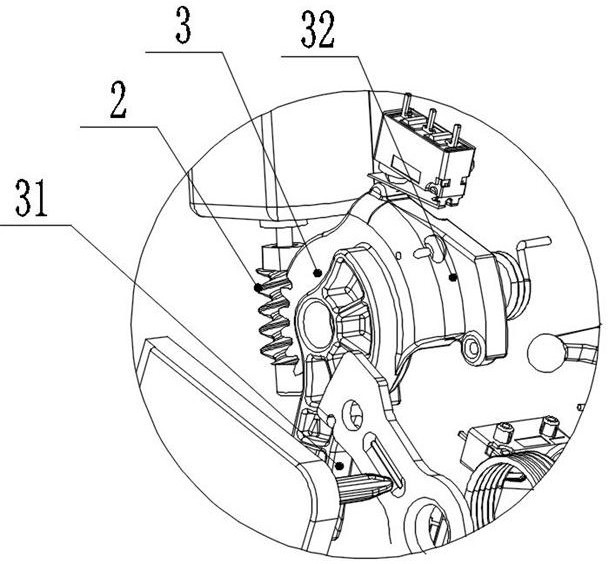

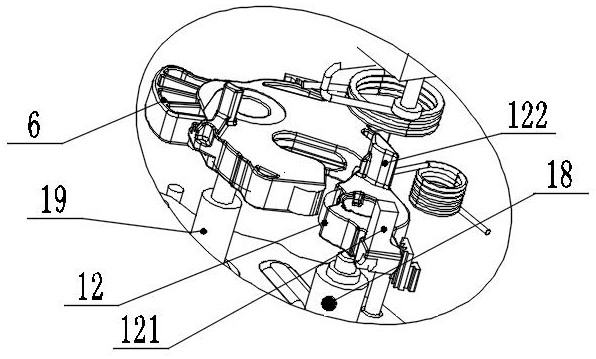

[0016] In the figure: a front middle door lock of an automobile, comprising a lock body 14 and a housing 15, characterized in that: the long cylinder 142 of the lock body 14 is sequentially sleeved with a connecting plate 13 and a locking linkage arm 4 and the outer locking rocker arm 9, the outer opening rocker arm 11 and the connecting plate 13 are sequentially sleeved on the short cylinder 141 from bottom to top, and the locking push rod 5 is arranged on the locking linkage arm 4 and the outer opening rocker arm 11 Above, the downward protrusion A at one end of the locking push rod 5 snaps into the groove of the locking linkage arm 4, and the downward protrusion B at the other end of the locking push rod 5 snaps into the outer swing In the concave cavity of the arm 11; the housing 15 is vertically arranged with the lock body 14, the middle part of the housing 15 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com