Cooking machine for preparing fermented soya beans

A steaming machine and technology of fermented soya bean, applied in application, food forming, food science, etc., can solve the problem of low efficiency of fermented soya bean cooking, achieve the effect of convenient and convenient water addition, novel and ingenious structure, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

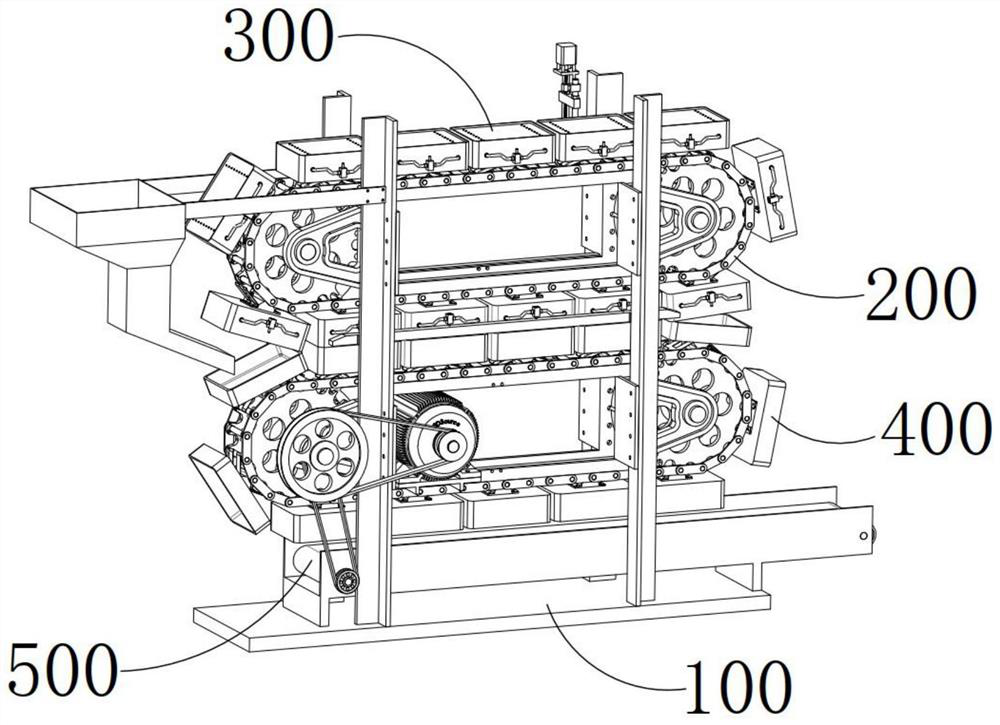

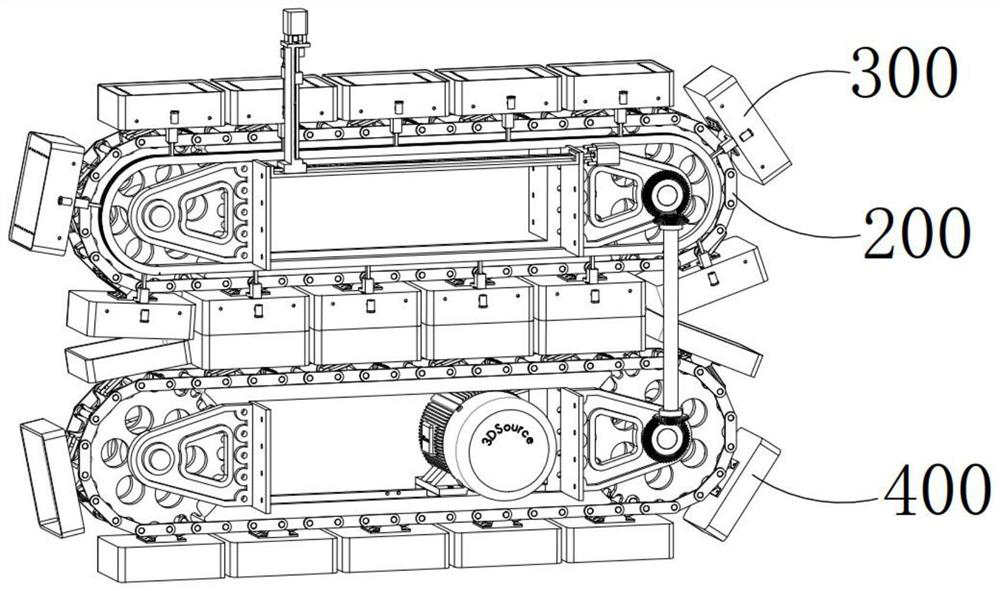

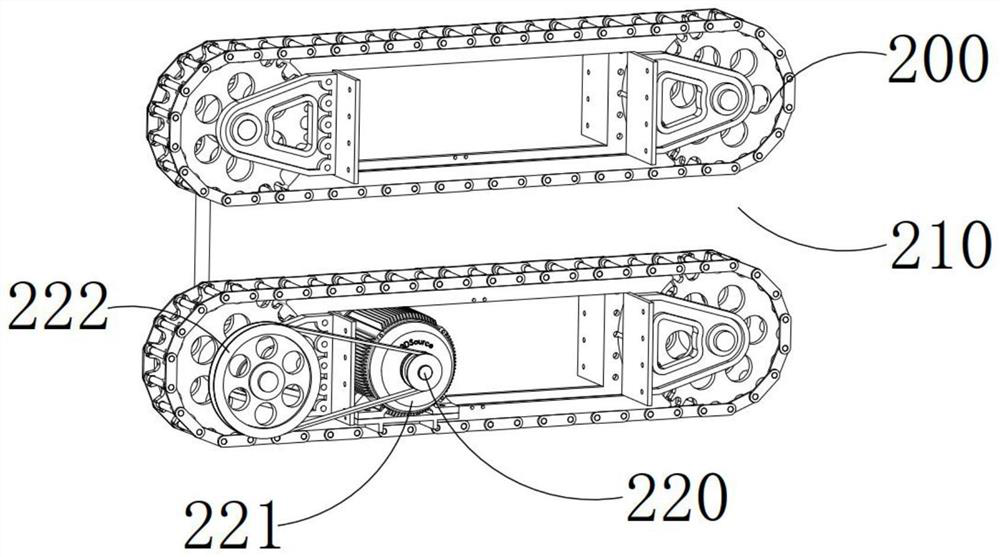

[0066] See Figure 1-24 , The cooking machine for making tempeh, which includes a mounting frame 100, a chain circulation mechanism 200, a steam generator 300, a cooking box 400, and a belt conveying mechanism 500. The chain circulation mechanism 200 is horizontally fixed on the mounting frame 100, There are two chain circulation mechanisms 200 and they are arranged symmetrically up and down. A cooking zone 210 is formed between the chain circulation mechanism 200 located above and the chain circulation mechanism 200 located below. One end of the cooking zone 210 is the starting end and the other end. As the end point, the steam generator 300 is movably arranged on the chain circulation mechanism 200 located above and can be driven to circulate in operation by the chain circulation mechanism 200. The steam generator 300 is provided with multiple and along the upper chain circulation mechanism 200. The cooking boxes 400 are arranged in an equally spaced array in the circulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com