Temperature-control carbon adding equipment for coal furnace

A coal furnace and coal technology, applied in lighting and heating equipment, combustion equipment, combustion control and other directions, can solve the problems of difficulty in adjusting the fire power of coal furnaces, adding more or less coal, and difficult to grasp the temperature of coal furnaces. Air circulation, the effect of ensuring the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

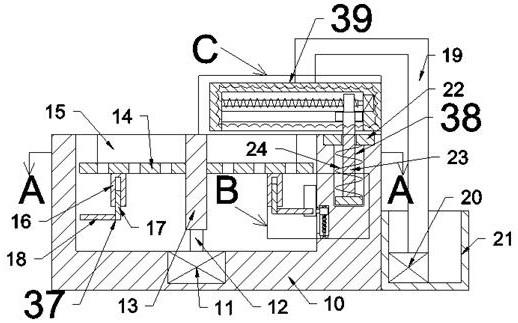

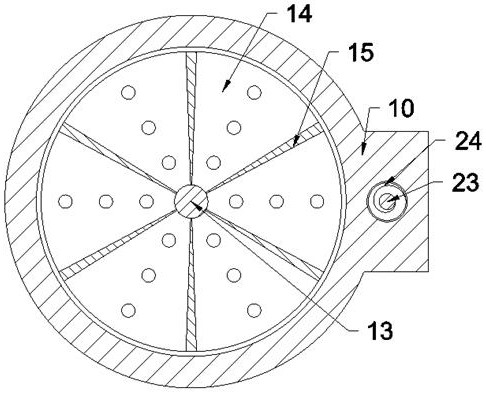

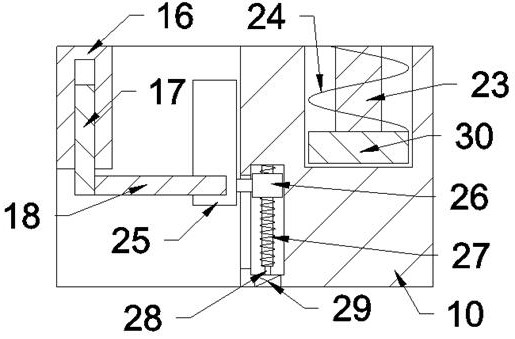

[0021] combined with Figure 1-5 The temperature-controlled carbon addition equipment for coal furnaces, the temperature control mechanism 37 and the slag removal mechanism 38 cooperate to control the temperature of the coal furnace and remove slag;

[0022] The temperature control mechanism 37 includes a heat response slide cylinder 16 fixedly connected with the carbon plate 14, and there are six heat response slide cylinders 16 in total. The carbon plate 14 is slidably connected with the coal furnace 10, and the heat response slide cylinder The inside of the cylinder 16 is slidably provided with a thermal response slide bar 17, and the outside of the thermal response slide bar 17 is fixedly provided with a gear rod 18, and the gear rod 18 can be in contact with the limit plate 25, and the limit plate 25 and the limit thread Block 26 is fixedly connected, and described limiting screw block 26 is threadedly connected with adjusting screw 27, and described adjusting screw 27 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com