Method for judging fatigue dangerous part of lug hole edge

A technology of dangerous parts and discrimination methods, applied in geometric CAD, design optimization/simulation, etc., can solve problems such as no longer applicable, and achieve the effect of simple and reliable judgment methods and easy promotion and calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

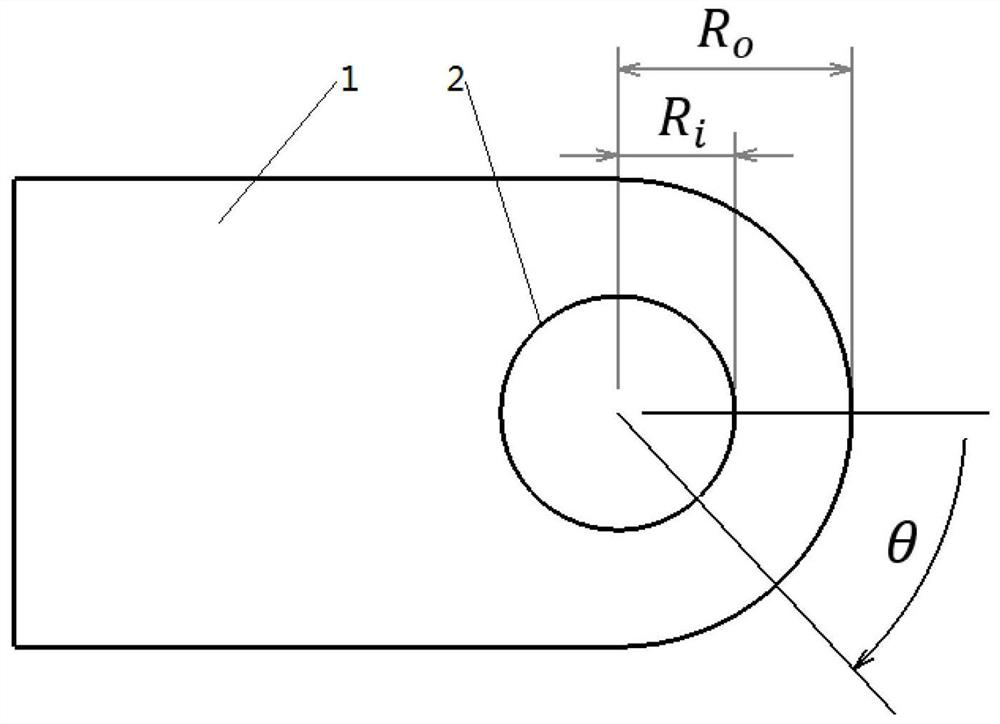

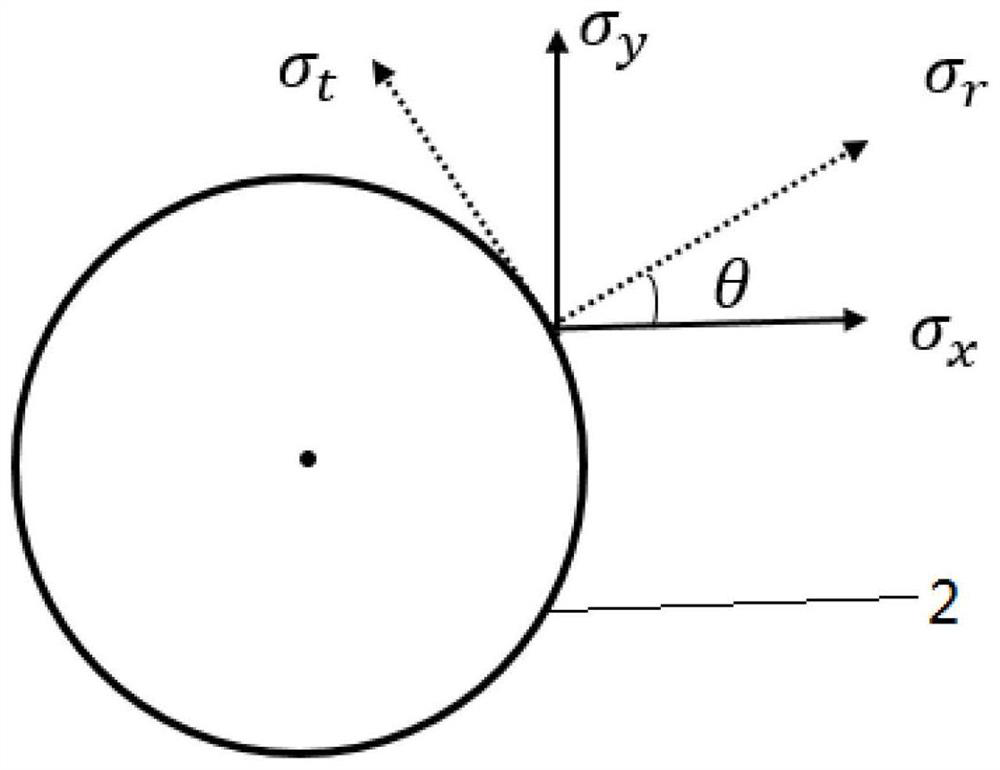

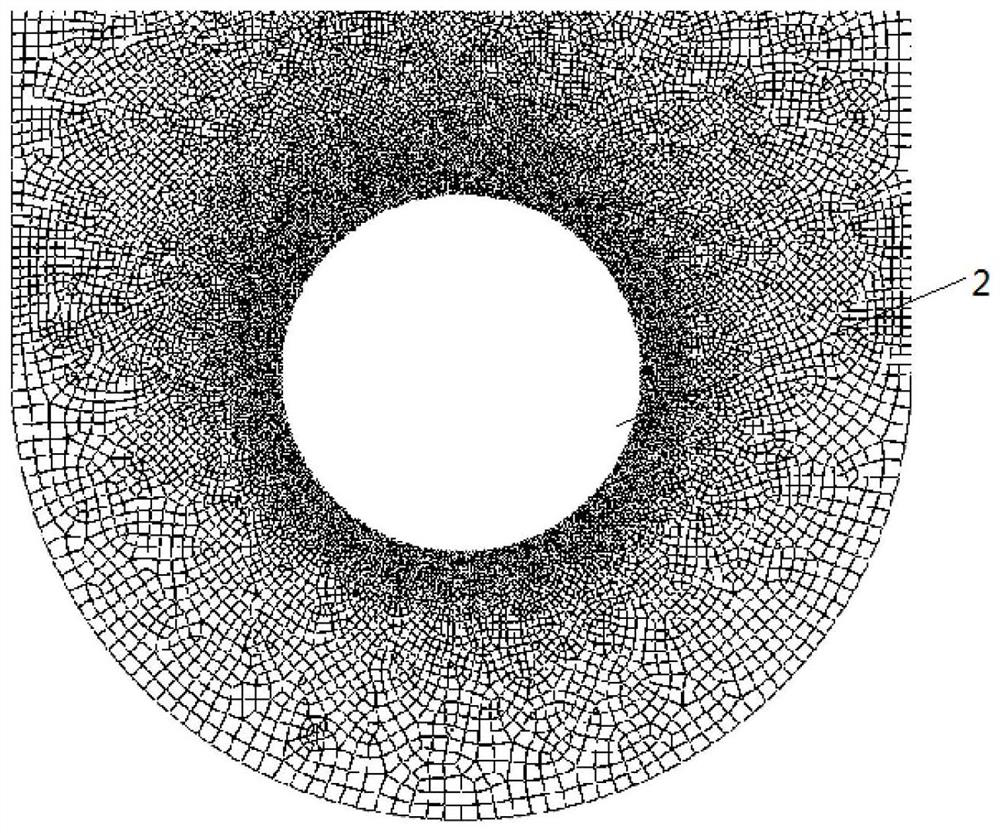

[0018] Referring to the accompanying drawings, the method for discriminating fatigue risk parts at the edge of the ear hole of the present application, the structural parameters of the ear are known, is characterized in that it comprises the following steps: 1) carrying out the above-mentioned ear structure 1 in the finite element analysis software. Grid division, set up finite element model, this finite element model is divided into not less than 360 mesh units by lug hole edge in implementation, establishes local cylindrical coordinate system in the center of lug hole 2; 2) in finite element analysis software Boundary conditions and loads are applied to the lug structure 1, and the stress value of the lug structure 1 in the global coordinate system under the load is obtained. The tangential stress of each grid unit on the edge of the lug hole is the stress on the hole wall 3) Transform the stress value of the lug structure 1 in the global coordinate system into the tangential...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com