Cleaning method of lithium battery coating die

A lithium battery and coating technology, which is applied to the device, coating, spraying device and other directions for coating liquid on the surface, which can solve the problem of inconsistent positioning and disassembly of the die head position, decreased consistency of coated products, and coated pole pieces. Scrap and other problems, to solve the problem of coating commissioning scrap, improve cleaning and maintenance efficiency, and avoid installation and positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

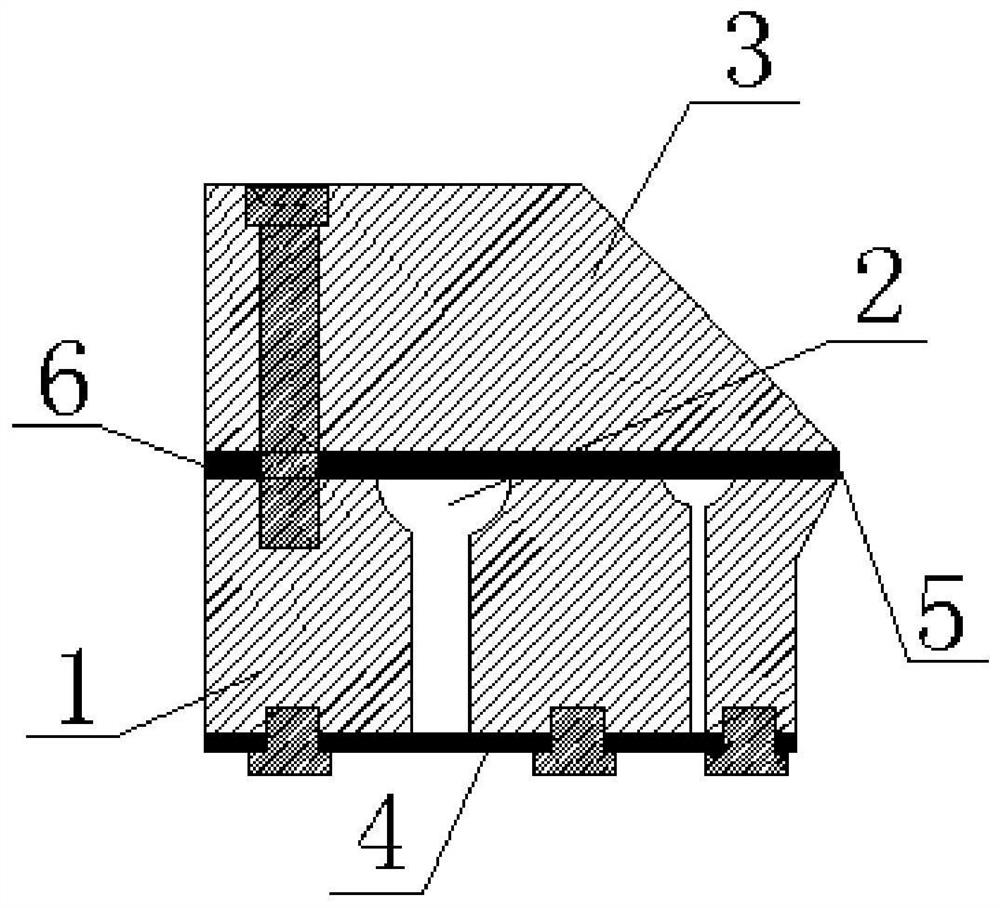

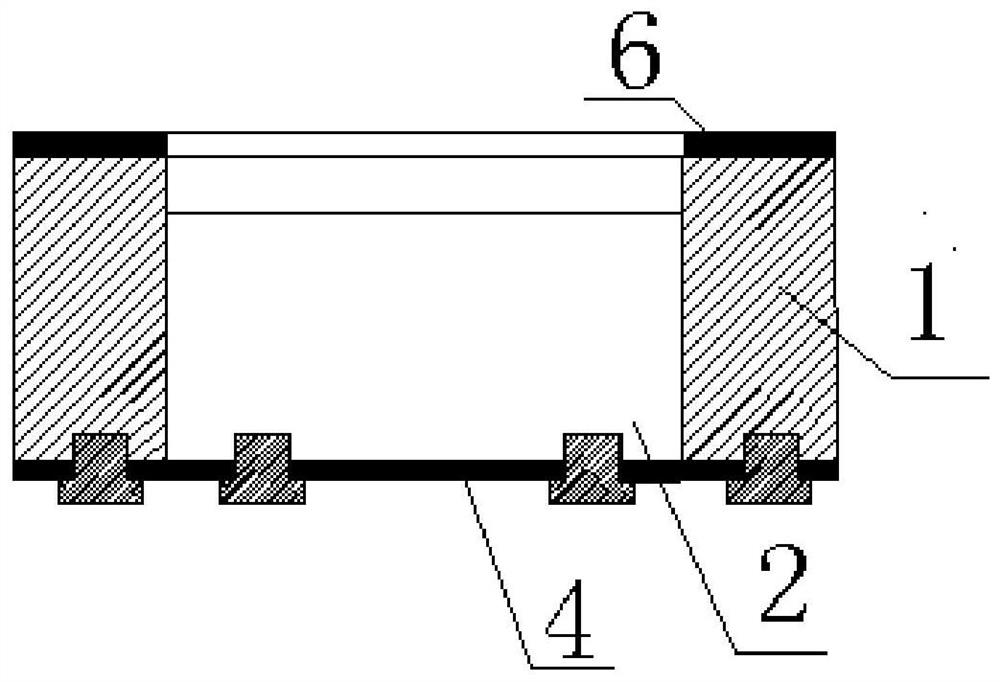

[0022] Such as figure 1 , figure 2 As shown, the lithium battery coating die head includes a lower die 1 , a cavity 2 , an upper die 3 , a cavity sealing plate 4 , a coating port 5 , a feed port (not shown in the figure), and a coating die 6 .

[0023] At least one material chamber 2 is opened on the lower mold 1, and the material chamber 2 is used to store the slurry used for coating. Setting a plurality of material chambers 2 can ensure that the flow rate of the slurry in the coating process meets the demand. The top runs through to the bottom, and the material cavity is a strip-shaped cavity whose length direction is along the left-right direction of the lower die 1 .

[0024] The material cavity 2 includes an upper cavity and a lower cavity, the upper cavity is the part from the top opening of the material cavity 2 to the middle of the material cavity 2, and the lower cavity is the part from the middle of the material cavity 2 to the material cavity 2 The bottom of the ...

Embodiment 2

[0031] The difference between this embodiment and Embodiment 1 is that the cleaning method of the lithium battery coating die head also includes the following steps: after the cavity sealing plate 4 is removed, the coating port 5 is blocked, and the feeding system passes through the feeding The mouth continues to supply material to the material cavity 2, so that the internal pressure of the material cavity 2 increases, and the residual slurry in the material cavity 2 is extruded by the new slurry and discharged from the bottom opening of the material cavity 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com