Patents

Literature

32results about How to "Improve cleaning and maintenance efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

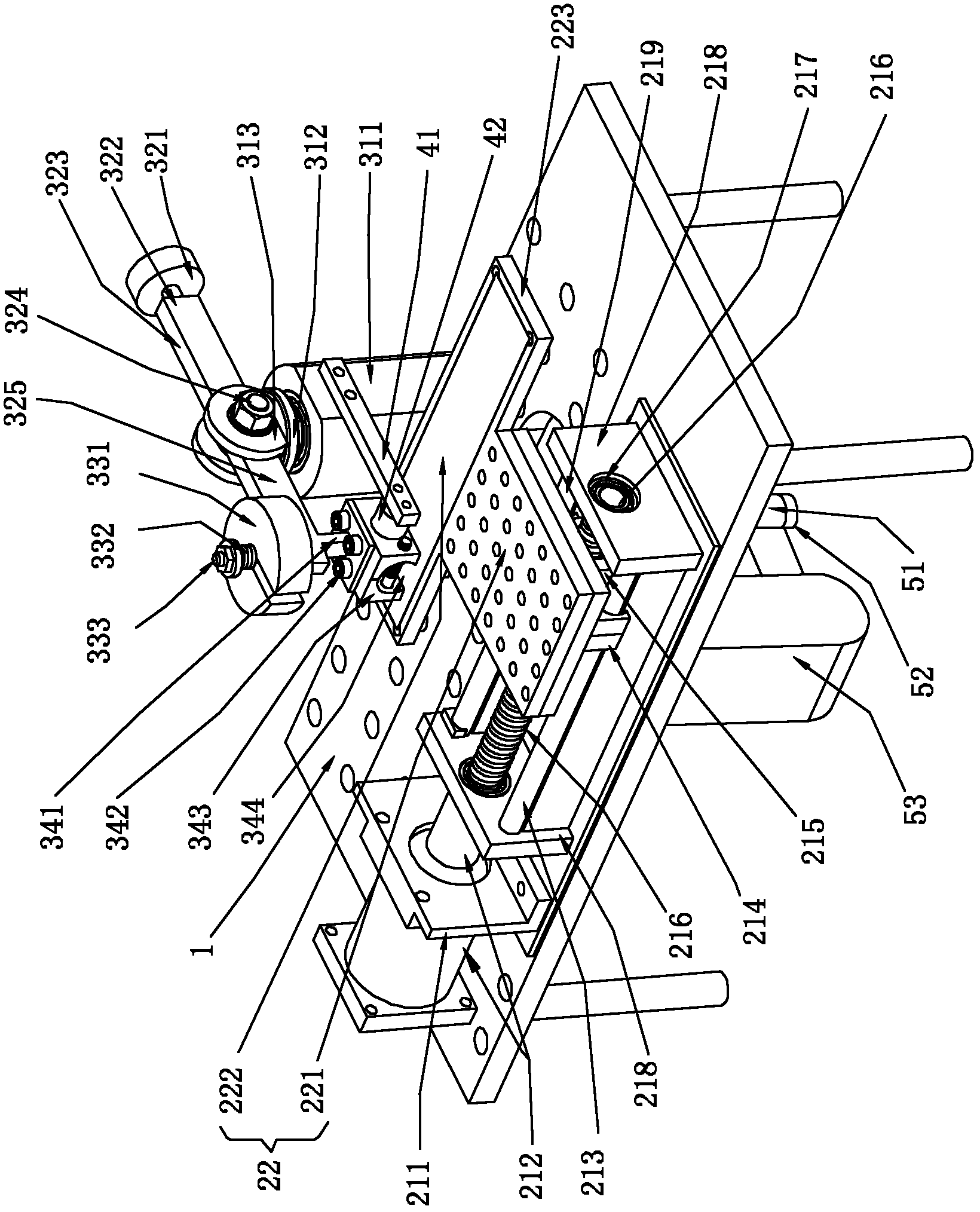

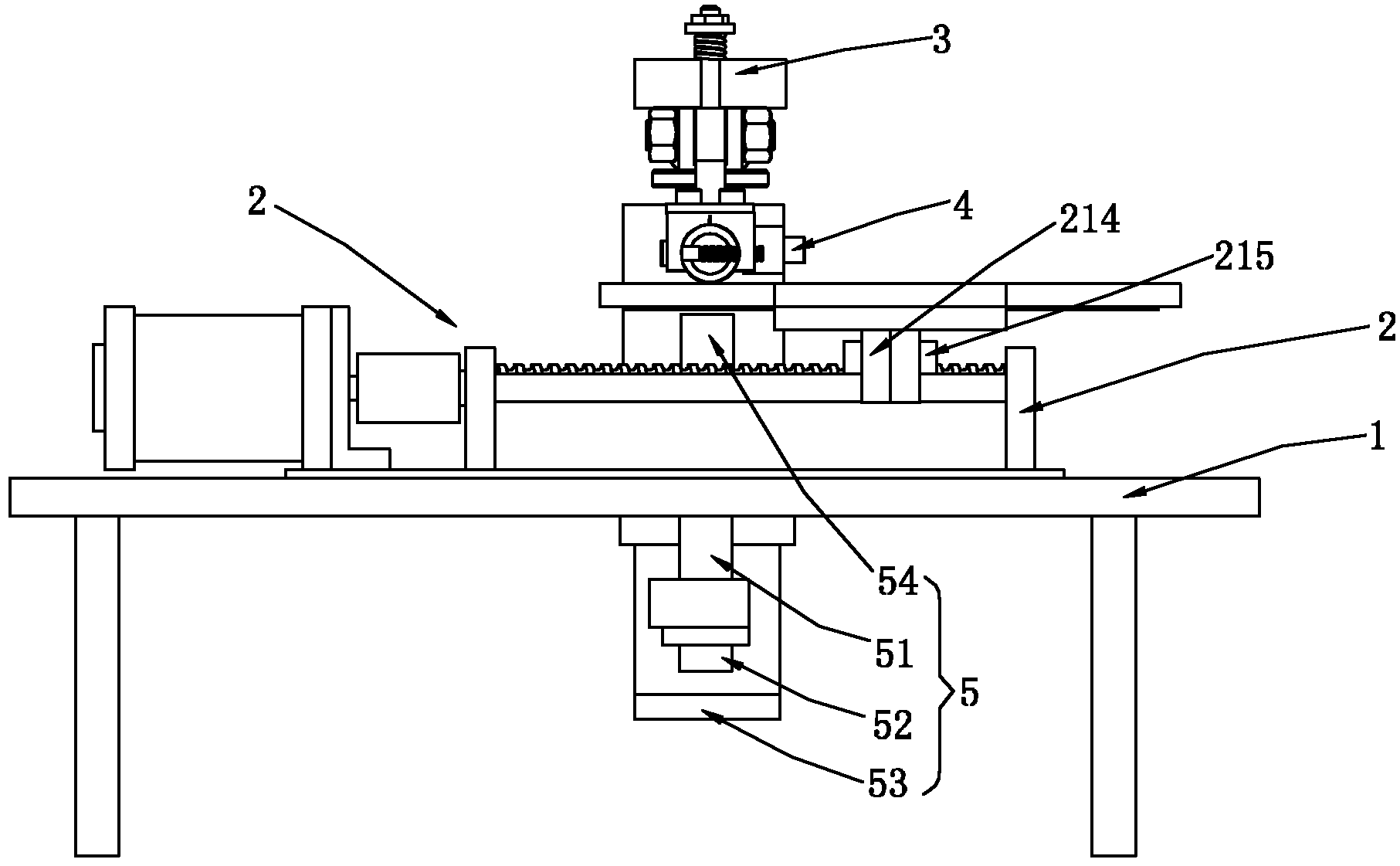

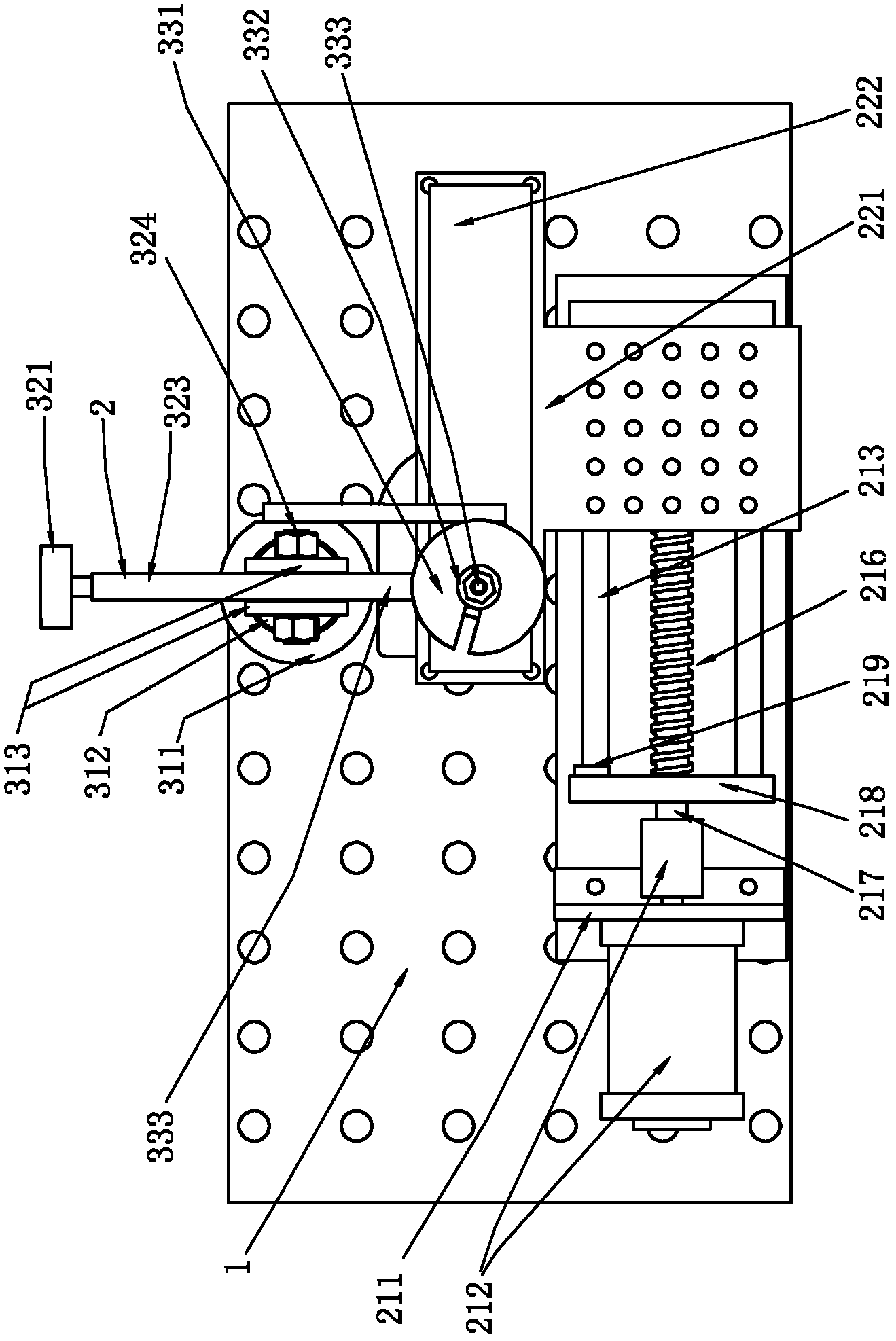

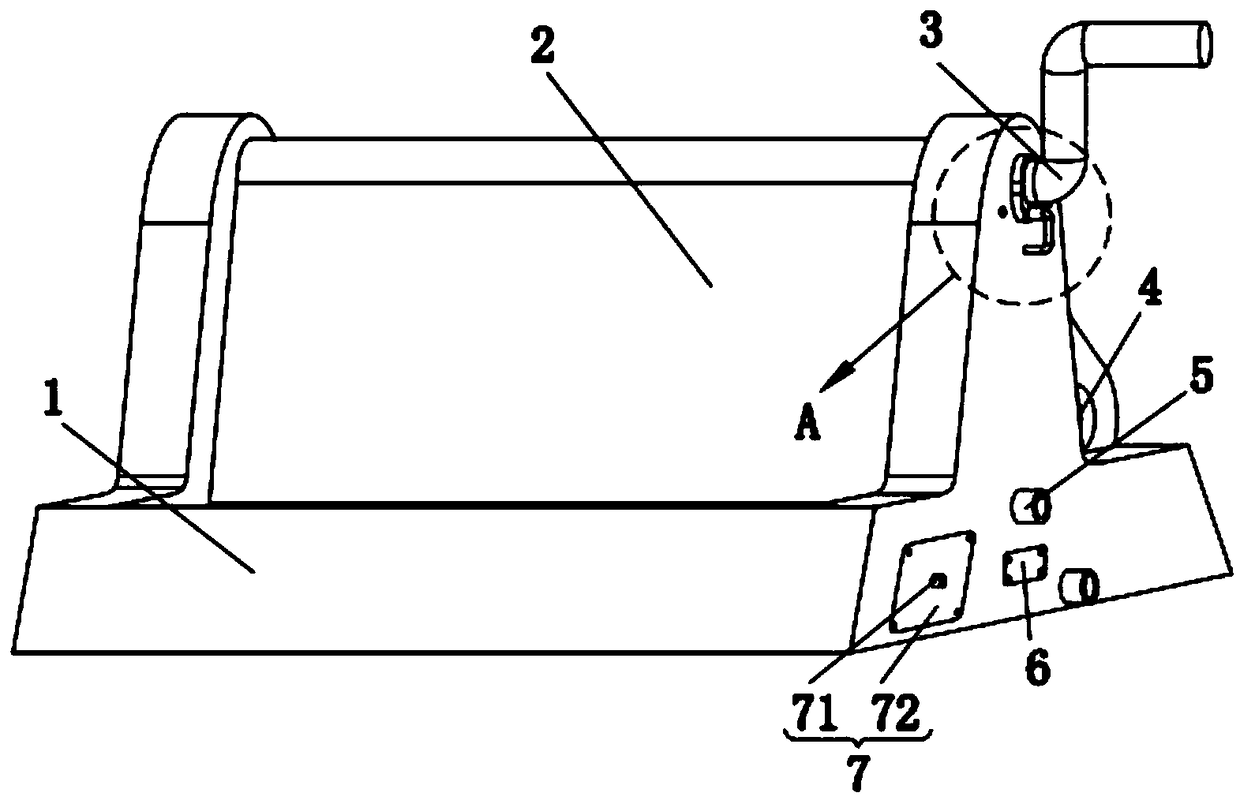

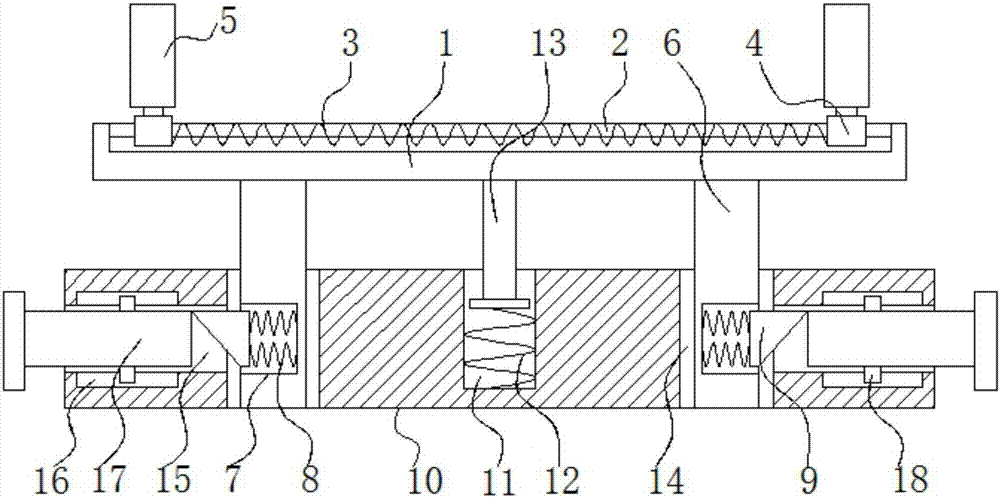

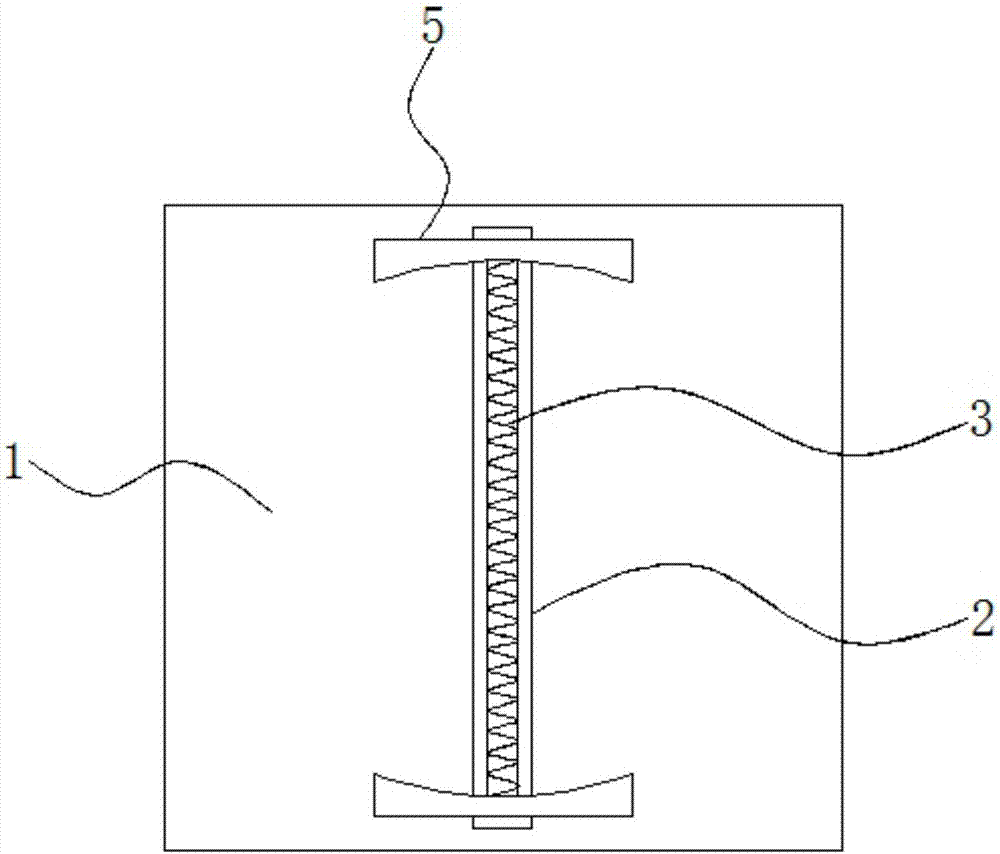

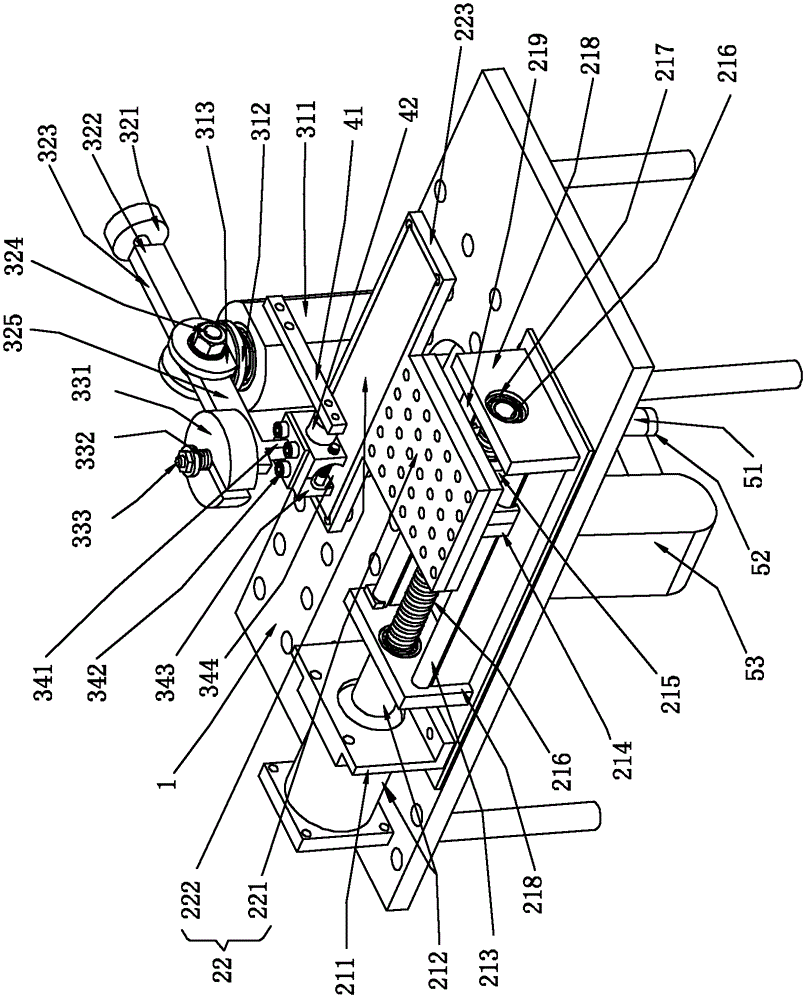

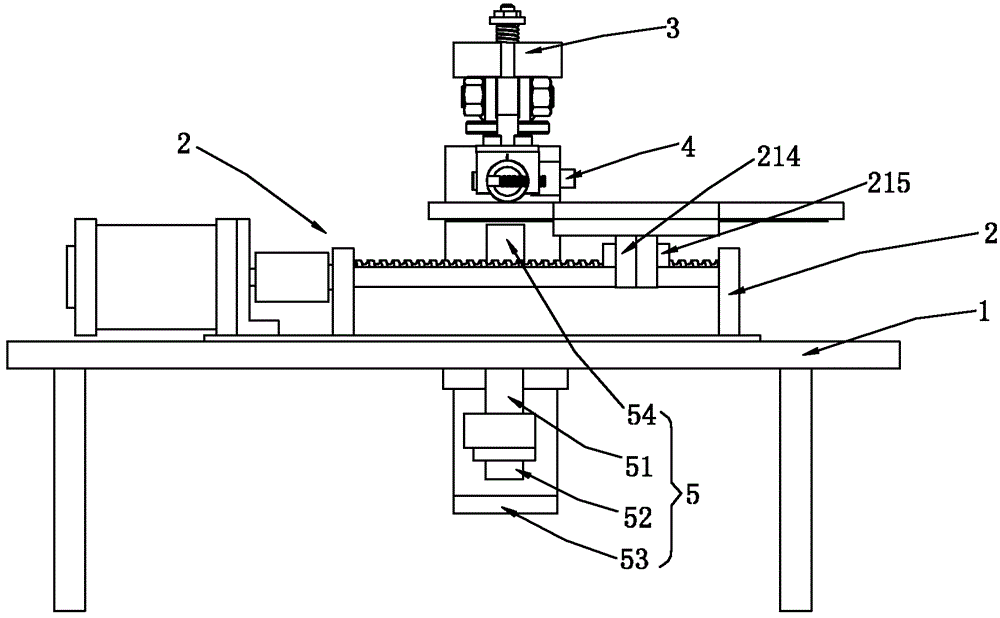

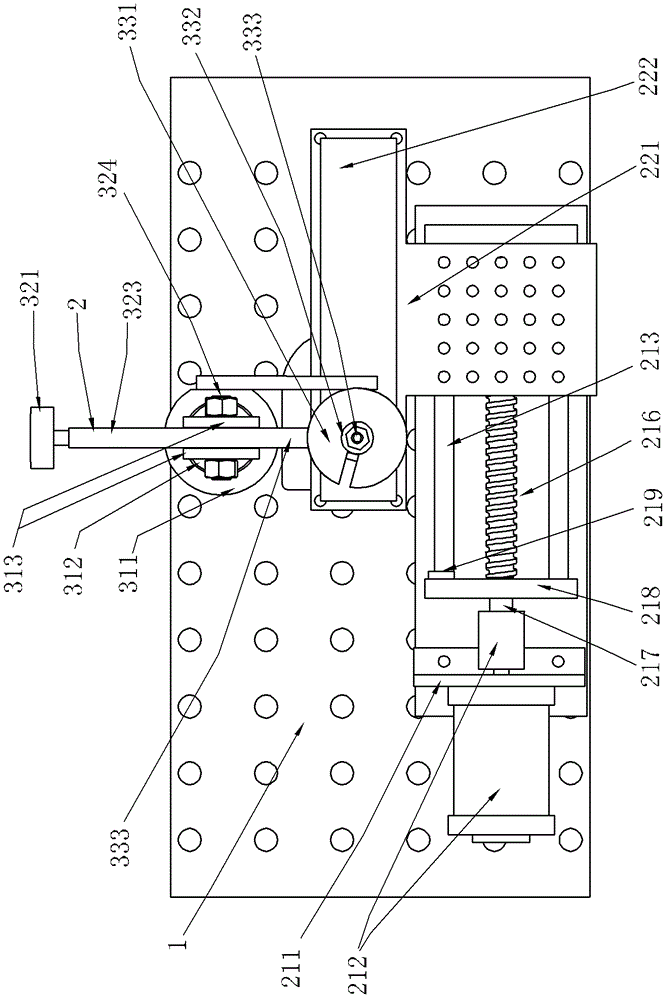

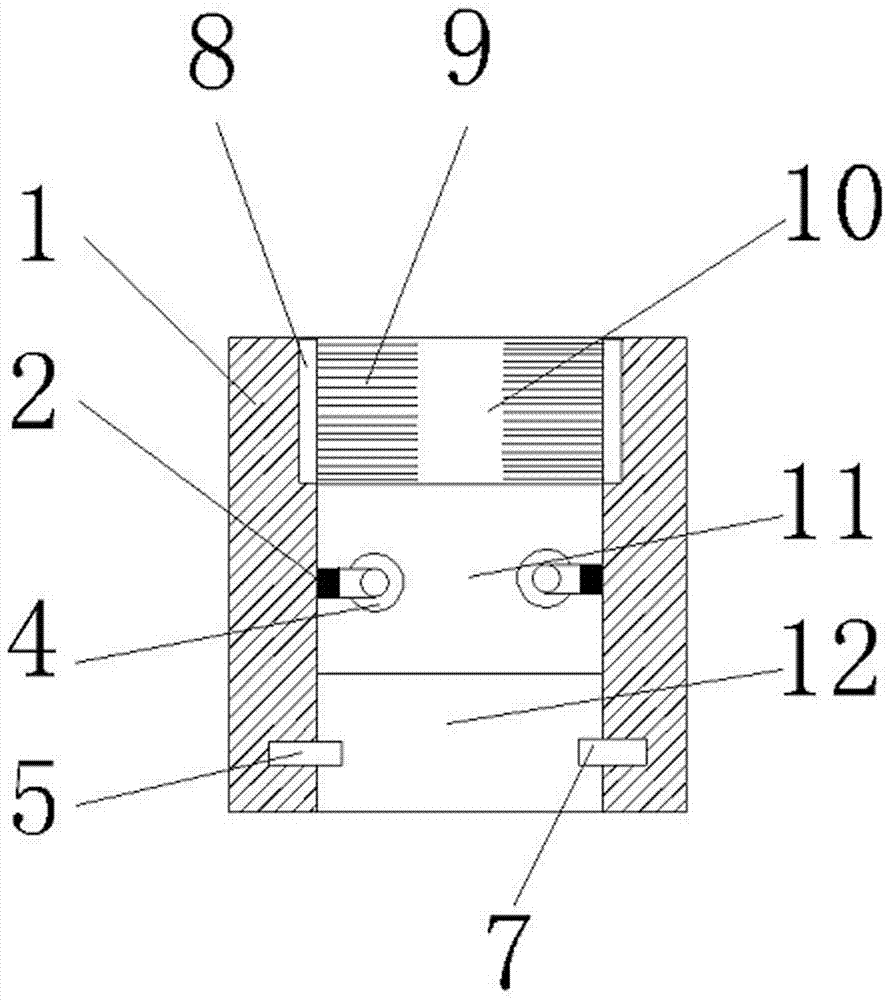

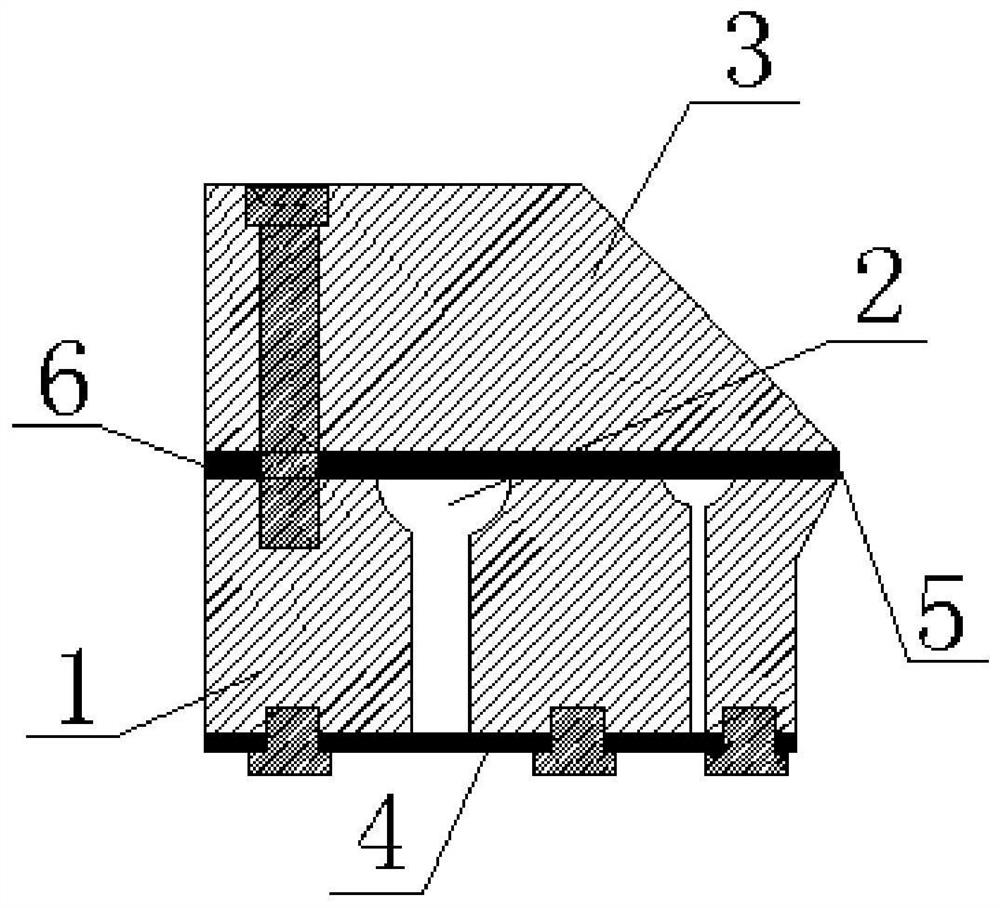

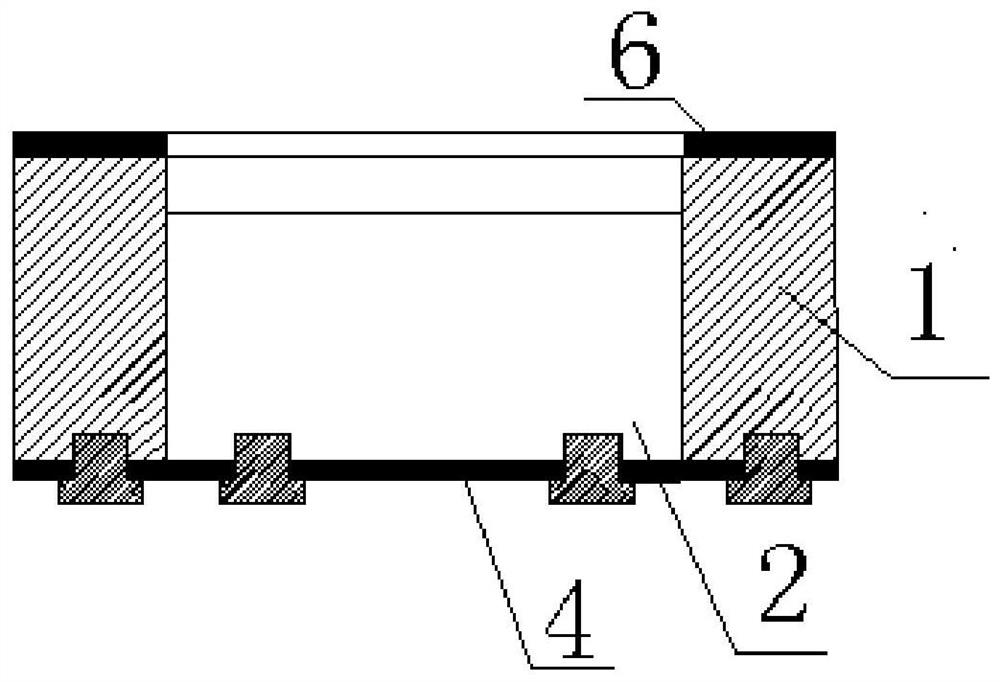

Direct-acting soft friction testing apparatus

InactiveCN102519867AImprove efficiencySimple structureUsing mechanical meansMaterial analysisElastic modulusFriction test

The invention relates to a direct-acting soft friction testing apparatus comprising a supporting stage. A lower sample fixing rack is arranged on the upper part of the supporting stage, and is connected with a driving mechanism. Under the driving of the driving mechanism, the fixing rack can move linearly in a plane. An upper sample assembly is arranged on the upper part of the lower sample fixing rack, and is connected to a loading mechanism which can apply a pressure downwards. A friction force detecting mechanism is connected with the upper sample assembly. Two samples with different elastic modulus are respectively fixed in the upper sample assembly and on the lower sample fixing rack. With the loading mechanism, the upper sample is pressed against the lower sample. The apparatus is advantaged in simple structure. Various testing parameters can be easily changed. When the lower sample is manufactured by using a transparent material, an elastic material surface deformation image and a residual liquid distribution image on a contact area can be acquired in real-time. Therefore, a solution is provided for optimizing selection of soft friction materials in complicated environments.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

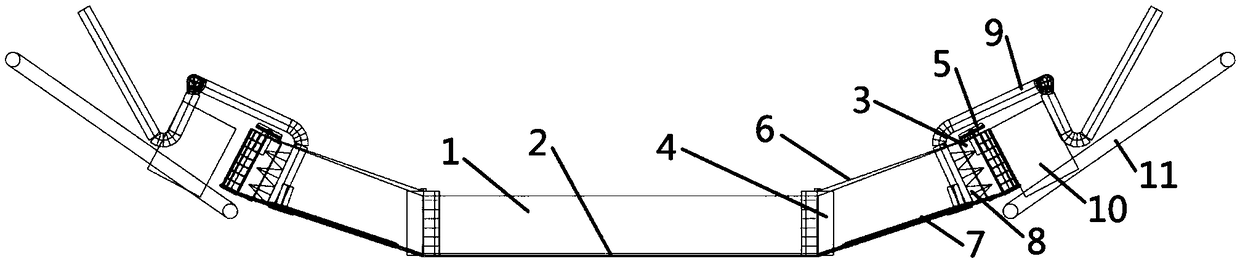

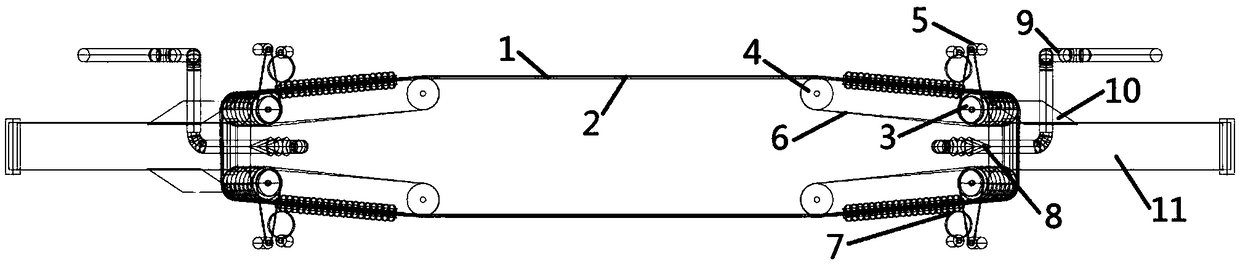

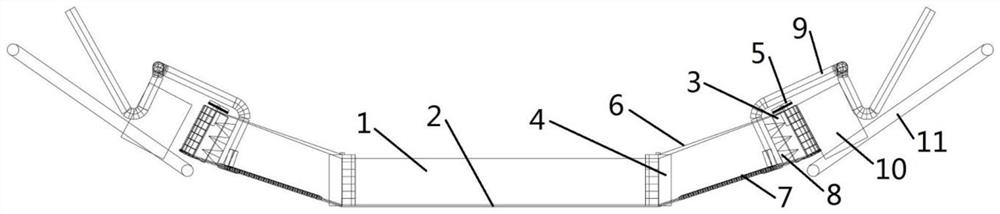

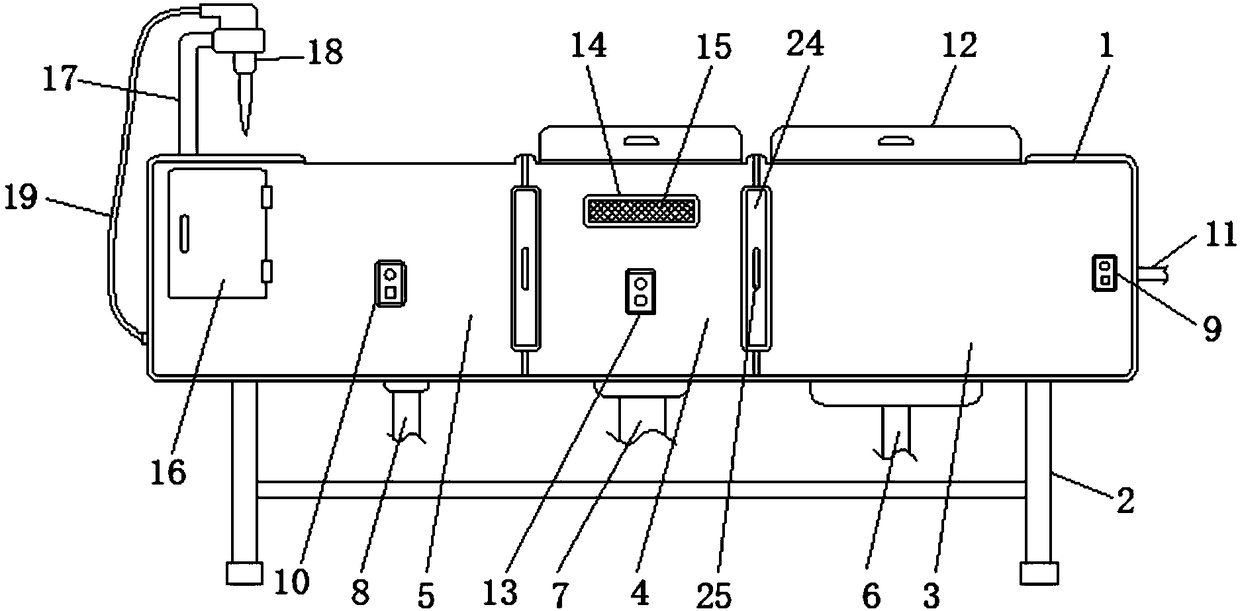

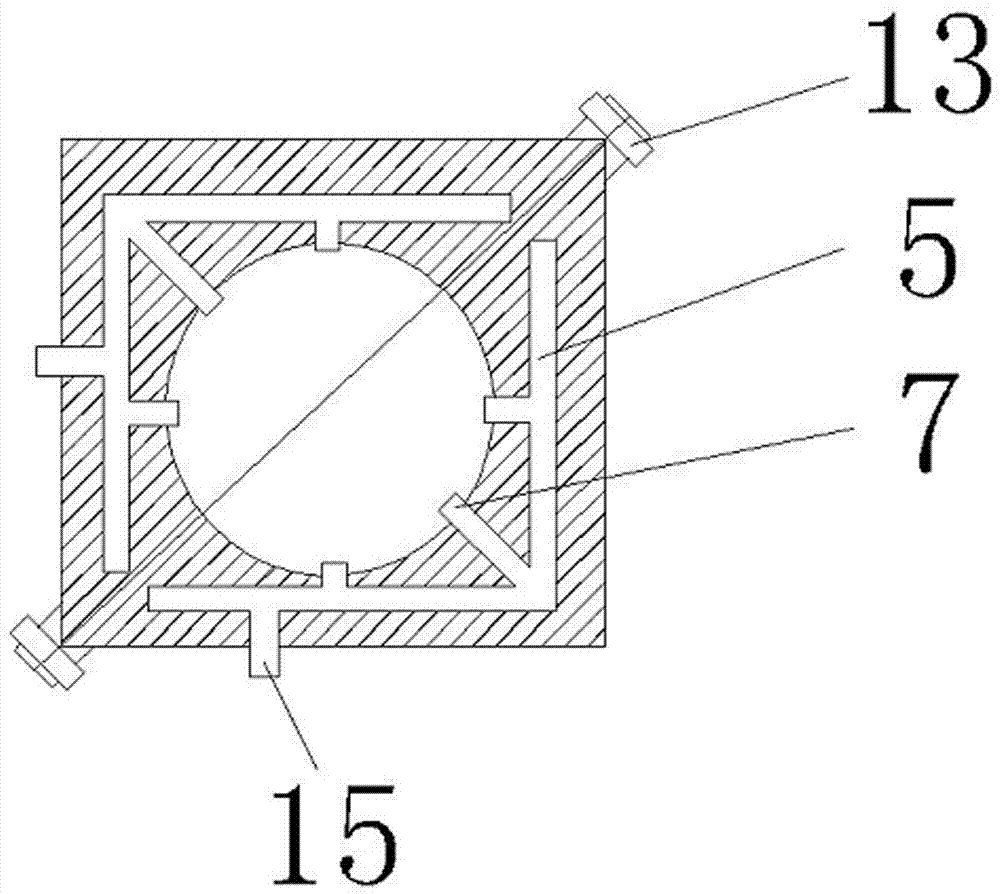

Automatic cleaning and trash blocking net device for power station seawater water-intaking open channel

ActiveCN109371916AHigh specific strengthSolution to short lifeArtificial water canalsPower stationWater channel

The invention relates to the technical field of nuclear power station maintenance, and particularly discloses an automatic cleaning and trash blocking net device for a power station seawater water-intaking open channel. The device is arranged in the water channel, dirt is intercepted through a concentric-square-shaped trash blocking net, moreover, the dirt in the water channel is taken away from the water surface by rotating, when the dirt rotates along with the concentric-square-shaped trash blocking net to the position between a driving roller and a follow-up roller, high-pressure water mistsprayed out of a back flushing nozzle is used for washing dirt which is adhered to the outer surface of the concentric-square-shaped trash blocking net away from a net body, the dirt is scraped awaythrough a back flushing baffle to be further collected onto a dirt conveying belt, and the dirt is transported to a collecting box at the top of a bank slope through the dirt conveying belt. Accordingto the device, electric control automatic cleaning is adopted to replace manpower to automatically intercept and clear the dirt in the seawater water-intaking open channel of the power station, so that the clearing and maintaining efficiency is improved, and the problem that the influences of weather and people on the existing trash blocking and trash removing construction activities are generally large is solved.

Owner:HAINAN NUCLEAR POWER CO LTD

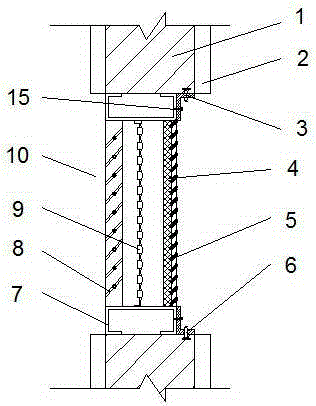

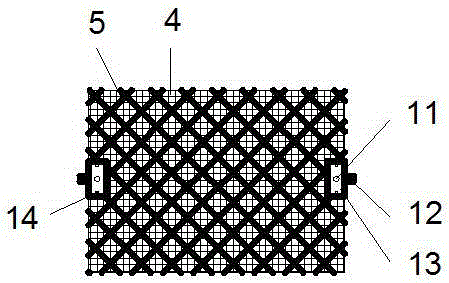

Ventilation window structure of substation

InactiveCN106532504ASmooth circulationEffective dustproofSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsWindow shutterEngineering

The invention provides a ventilation window structure of a substation. The ventilation window structure comprises a wall body and a ventilation opening, wherein the ventilation opening is provided with a border; a shutter is arranged in the border; the part between the outer side surface of the border and the inner wall of the ventilation opening is filled with a hemp thread; a metal net is arranged at the indoor side of the shutter in the border; a dustproof net is arranged at the outer side of the metal net; a plurality of large net holes are arranged in the metal net; a plurality of small net holes are arranged in the dustproof net; fixed devices are arranged at two sides of the metal net; a release button is arranged on each fixed device and is connected with a chuck through a spring mechanism in the fixed device; clamping grooves matched with the chucks are arranged in the border corresponding to the fixed devices; and angle steel is arranged between the periphery of the indoor side of the border and the inner wall of the ventilation opening; and two wall surfaces of the angle steel are locked on the inner wall of the ventilation opening and the peripheral surface of the indoor side of the border by using expansion bolts and rivets respectively. The ventilation window structure of the substation is simple and is convenient to clean and maintain; good ventilation and exhausting are achieved; and the dust is effectively prevented.

Owner:国网山东济南市长清区供电公司 +1

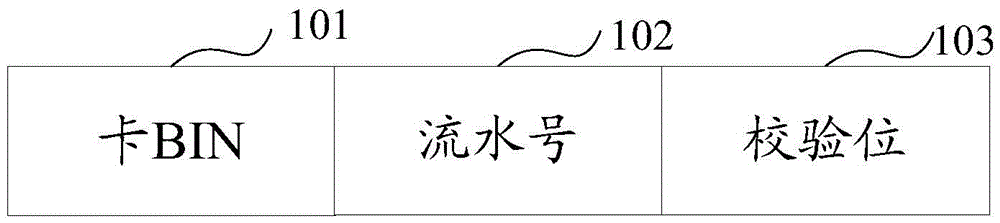

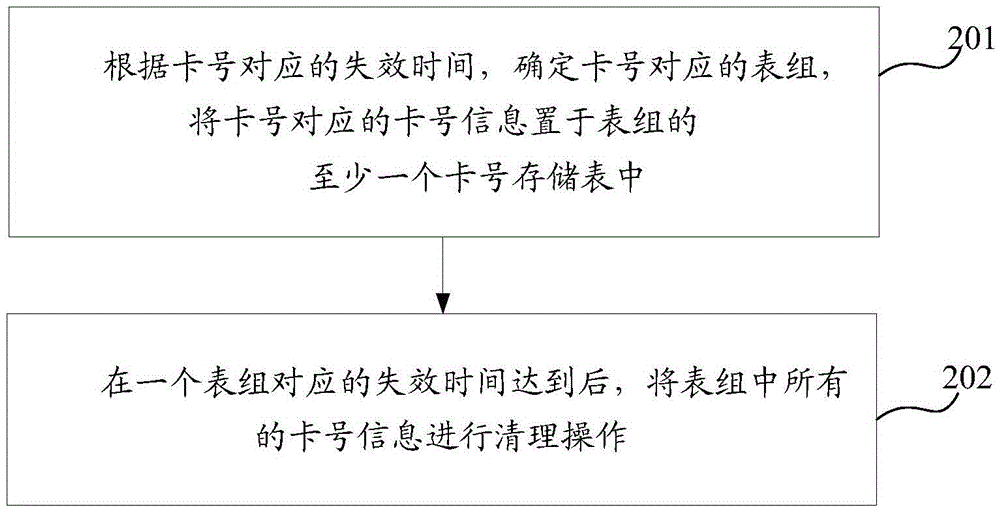

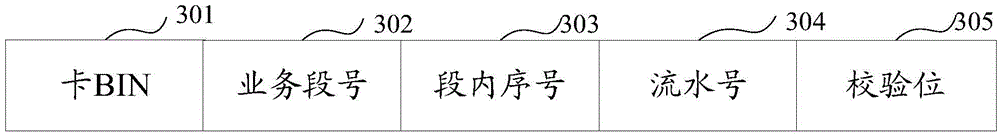

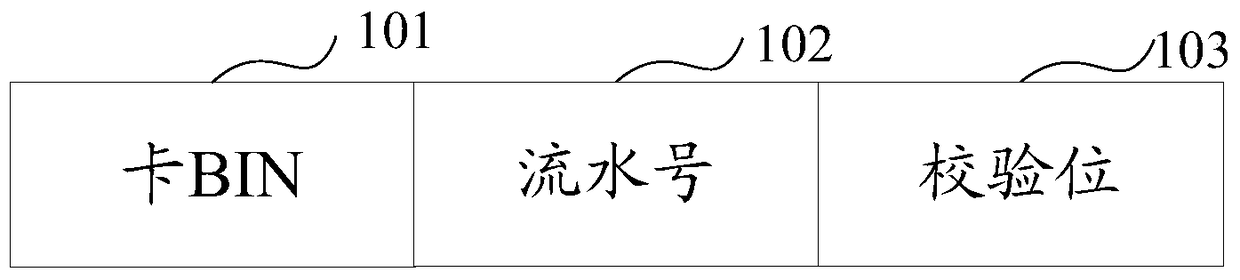

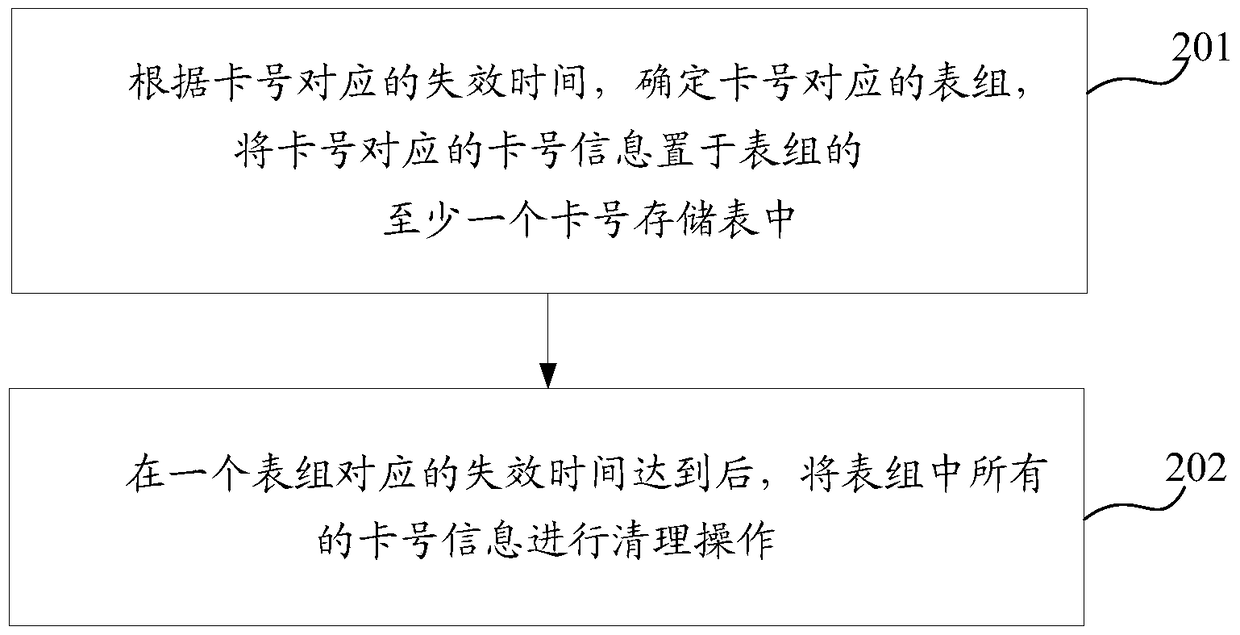

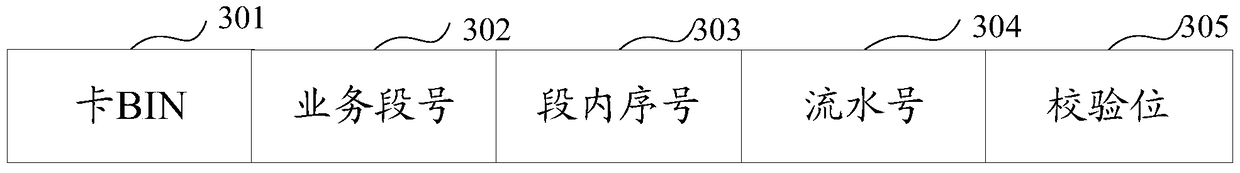

Method and apparatus for processing card number data

ActiveCN105930331AImprove cleaning and maintenance efficiencyReduce maintenance costsDatabase updatingPayment architectureComputer hardwareData treatment

The invention discloses a method and apparatus for processing card number data. According to the failure time corresponding to a card number, a table group corresponding to the card number is determined, and card number information corresponding to the card number is put into at least one card number storage table of the table group; the table group is composed of a plurality of card number storage tables, each table group corresponds to one failure time, the failure time corresponding to all the card numbers in the table group is the same as the failure time corresponding to the table group, and the card number information includes the card number and associated data with the card number; and when the failure time corresponding to one table group is reached, all card number information in the table group are cleaned up. The method and apparatus provided by the embodiment of the invention can improve the cleaning maintenance efficiency of the method for processing the card number data and reduce the maintenance cost.

Owner:CHINA UNIONPAY

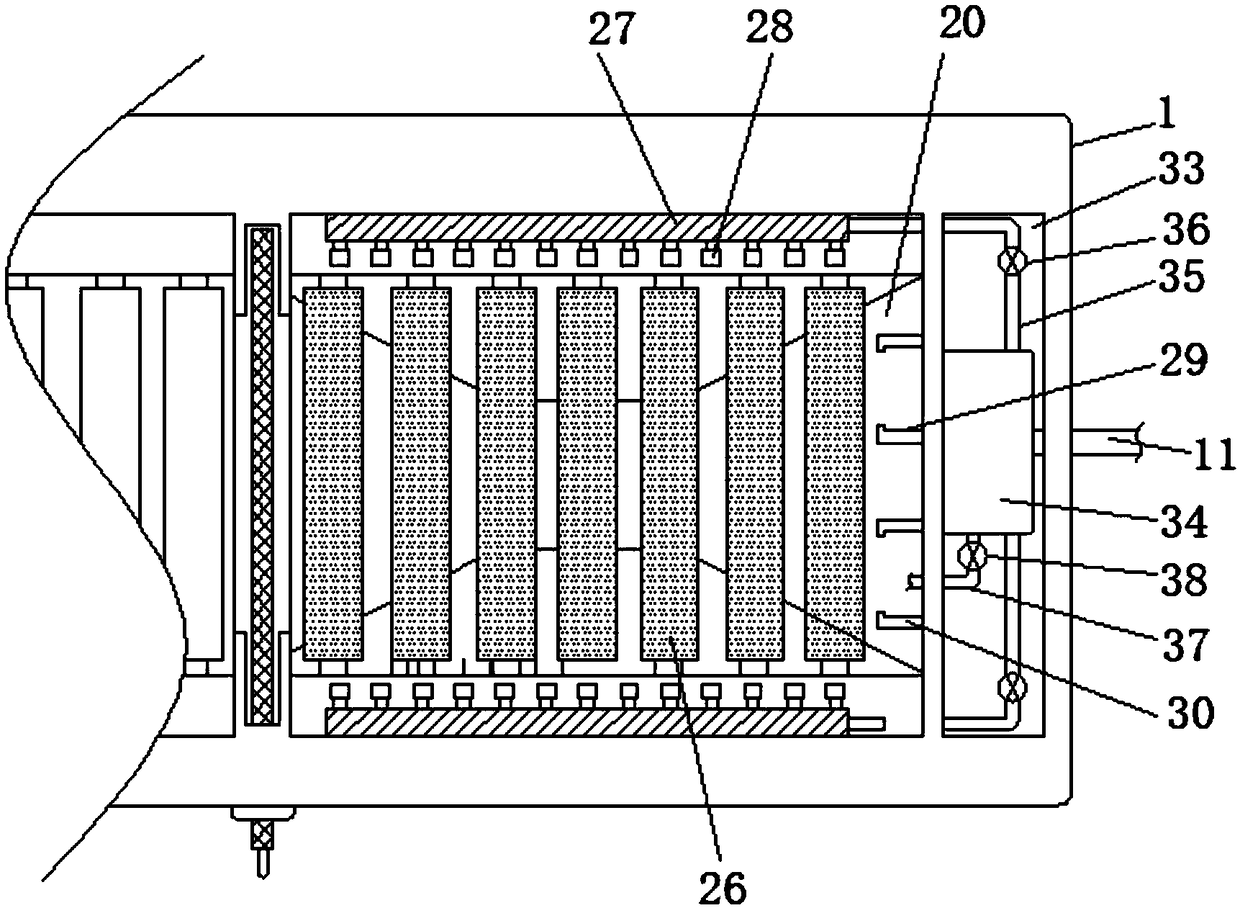

Heavy metal waste liquid treatment process

ActiveCN109133485AImprove efficiencyImprove cleaning and maintenance efficiencyWater contaminantsTreatment involving filtrationIndustrial wasteHeavy metals

The invention relates to the technical field of an industrial waste liquid treatment process, in particular to a heavy metal waste liquid treatment process. The heavy metal waste liquid treatment process comprises the following steps: heavy metal waste liquid is introduced into a filtering box and large particles in the metal waste liquid are filtered through the filtering box; the filtering box is arranged above waste liquid treatment equipment, and the filtering box and the waste liquid treatment equipment are connected through an electromagnetic disk; the filtered waste liquid is introducedinto the waste liquid treatment equipment; two electromagnetic disks are symmetrically arranged on the inclined surface of a supporting sleeve of the waste liquid treatment equipment; the lower end face of each electromagnetic disk is fixedly connected with the upper end of an iron rod, a net bag is arranged at the lower end of the iron rod and the lower end of the iron rod extends into a cavityof the waste liquid treatment equipment; when the waste liquid treatment equipment adjusts the position of a filtering structure, the net bag is dismantled in the process of the dismantling the filtering structure, and performing unified cleaning at the same time so as to improve the efficiency of the waste liquid treatment equipment. By the heavy metal waste liquid treatment process, heavy metalparticles can be efficiently eliminated.

Owner:江苏邦腾环保技术开发有限公司

LED streetlamp capable of being cleaned automatically

InactiveCN110645520APull out and replace in timeEasy to cleanMechanical apparatusLighting support devicesEngineeringStructural engineering

The invention discloses an LED streetlamp capable of being cleaned automatically, the LED streetlamp comprises a box in which an inner cavity is arranged, wherein a lower side pipe is fixedly arrangedon the lower end wall of the inner cavity; an opening pipe inner cavity is arranged in the lower side pipe; the pipe inner cavity communicates with the inner cavity; a distribution block is fixedly arranged on the lower end wall of the pipe inner cavity; the distribution block is opposite to the inner cavity; a bottom block is fixedly arranged on the lower end face of the lower side pipe; a connection pipe is arranged in the bottom block; and a symmetrical switch valve is arranged in the connection pipe in a communicating manner. The equipment provided by the invention is simple in structure,adopts a rotary cleaning mode to efficiently and accurately clean the multiple LED lamp groups, and thus the cleaning and maintenance efficiency of the LED lamps is greatly improved; and the multiplearranged LED lamp groups are used at the same time, and after being failed, the certain LED can be effectively and timely replaced and supplemented, so that the use effect of the LED is improved, andthe labor burdens of workers are reduced.

Owner:朱佳甜

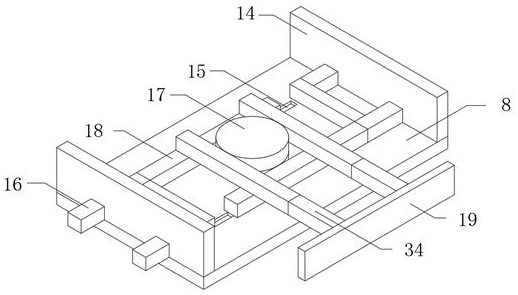

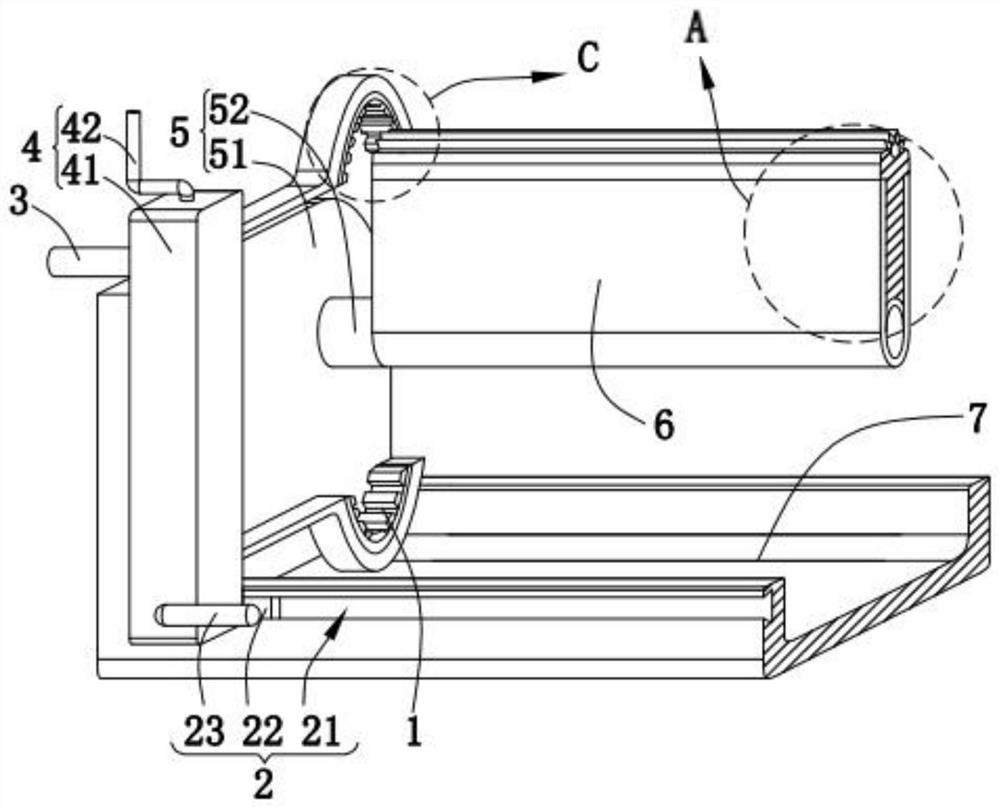

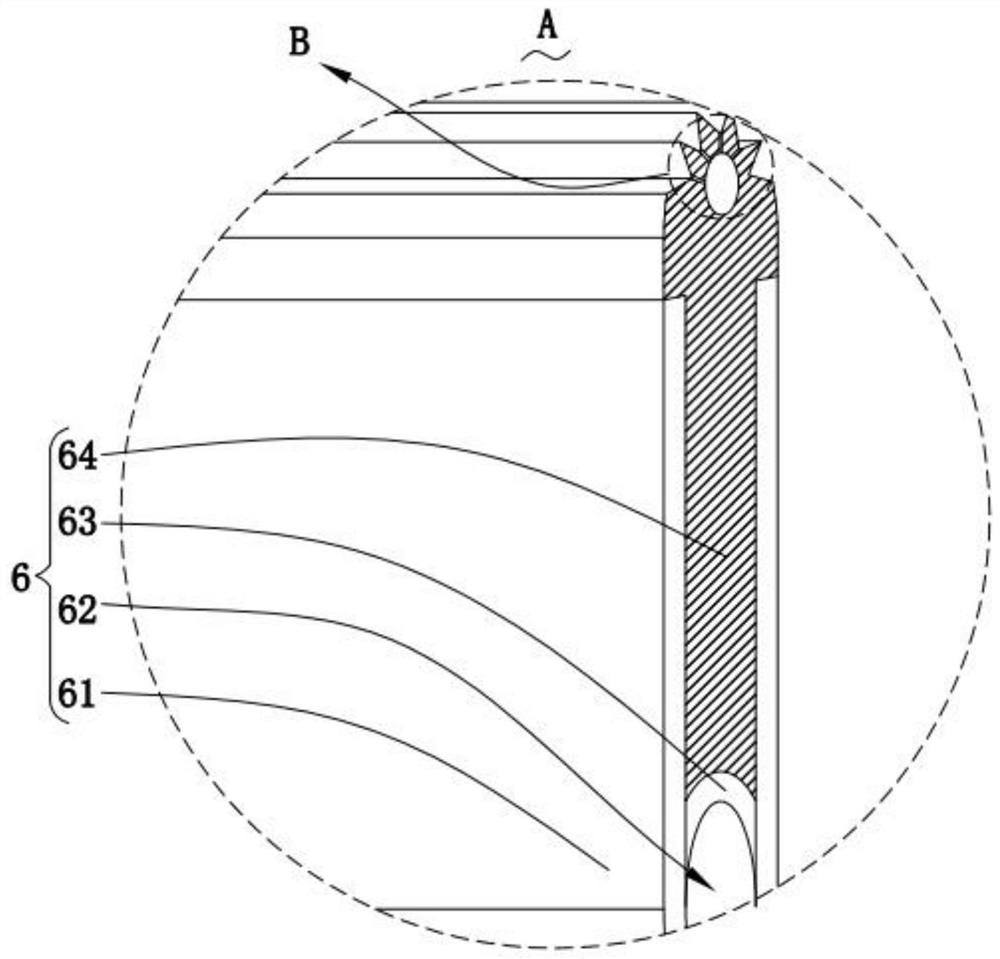

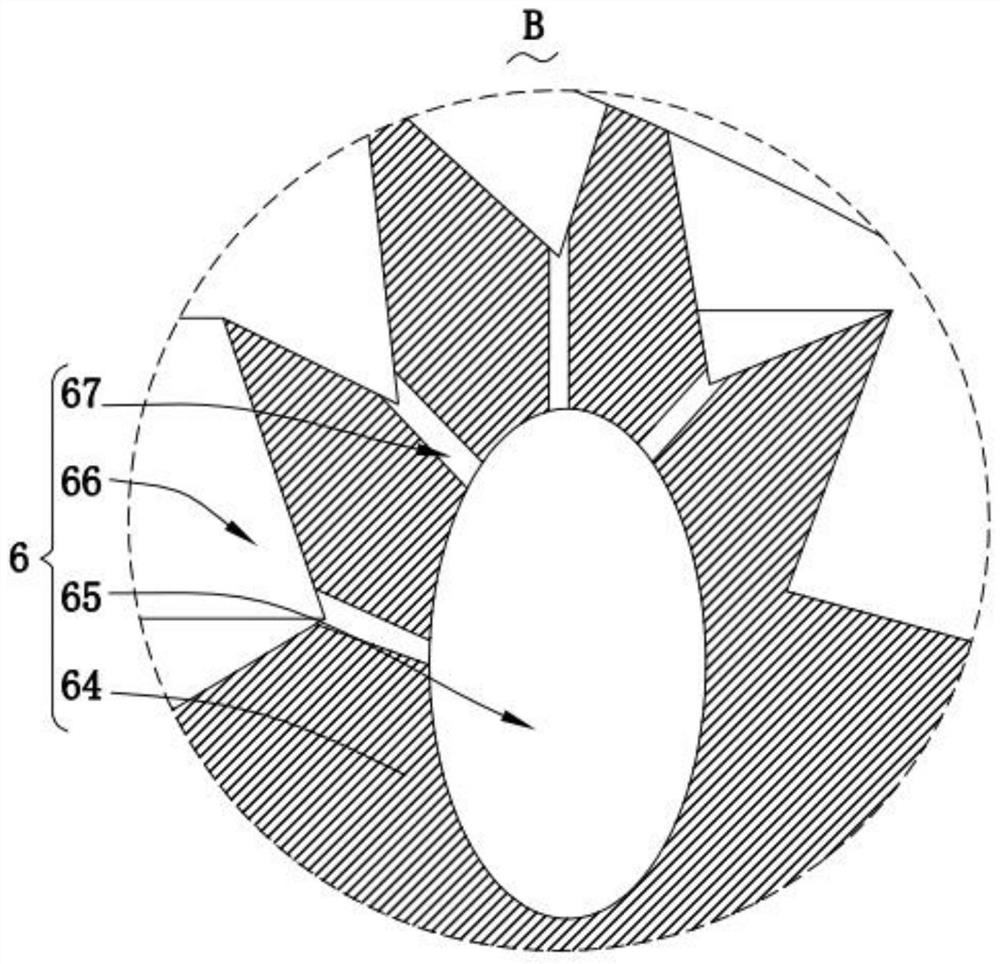

Paint spraying tray capable of being rapidly replaced and cleaned for aluminum alloy hub machining

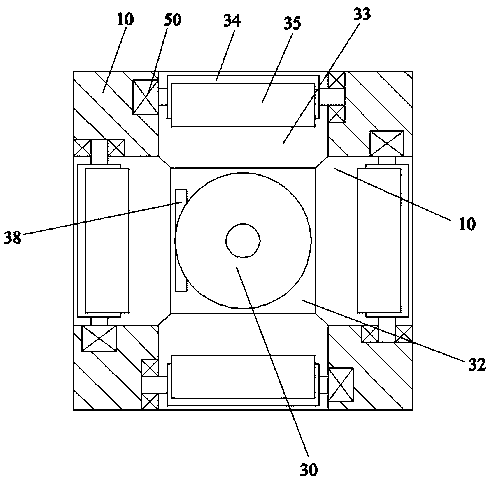

InactiveCN107570358AEasy to disassembleSimple device structureSpraying apparatusEngineeringAluminium alloy

The invention discloses a paint spraying tray capable of being rapidly replaced and cleaned for aluminum alloy hub machining. The paint spraying tray comprises a main body, wherein two fixing rods aresymmetrically welded at the bottom part of the main body, and the fixing rods are perpendicular to the main body; first grooves are formed in the ends, away from the main body, of the two fixing rods, and the opening directions of the two first grooves are far away from each other; two second springs are connected to each of the interiors of the first grooves, and the ends, extending out of the first grooves, of the second springs are connected with limiting blocks; and a mounting base is arranged below the main body, wherein a second groove is formed in the middle position of the mounting base, a third spring is arranged in the second groove in a sleeved mode, and the end, extending out of the second groove, of the third spring is connected with a restoration rod. The paint spraying trayhas the advantages of being simple in structure and novel in design, the tray can be mounted and dismounted conveniently, tray cleaning time is shortened, and tray cleaning and maintaining efficiencyis improved.

Owner:ZHEJIANG CHANGXING KECHUANG METAL PROD CO LTD

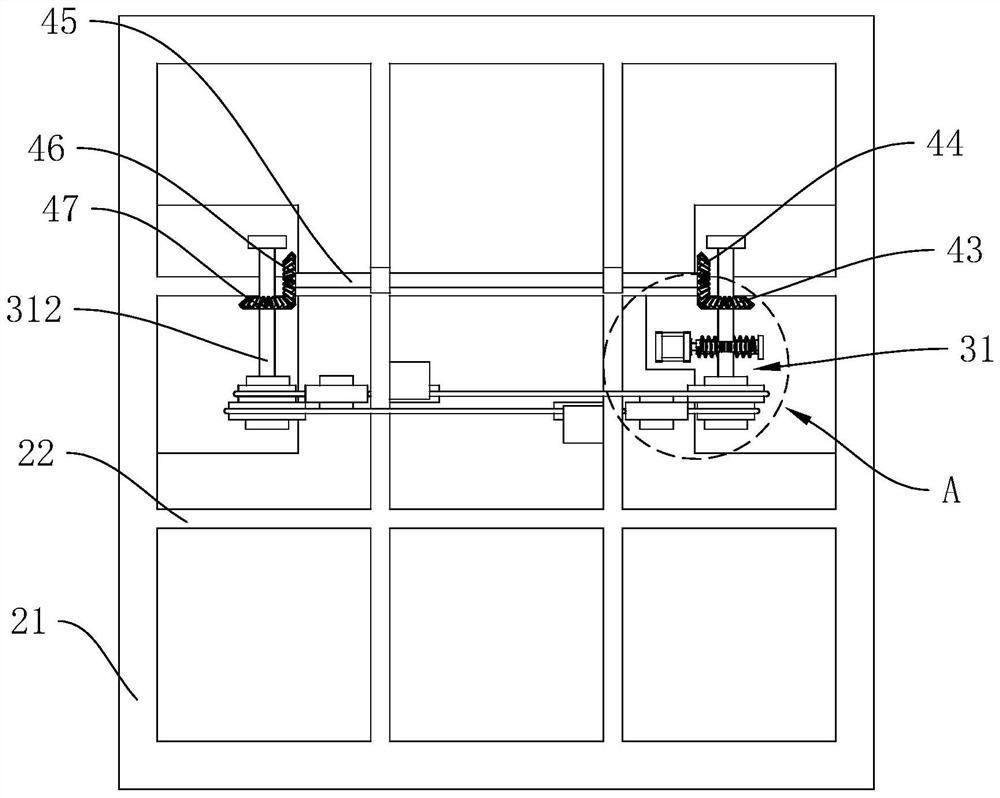

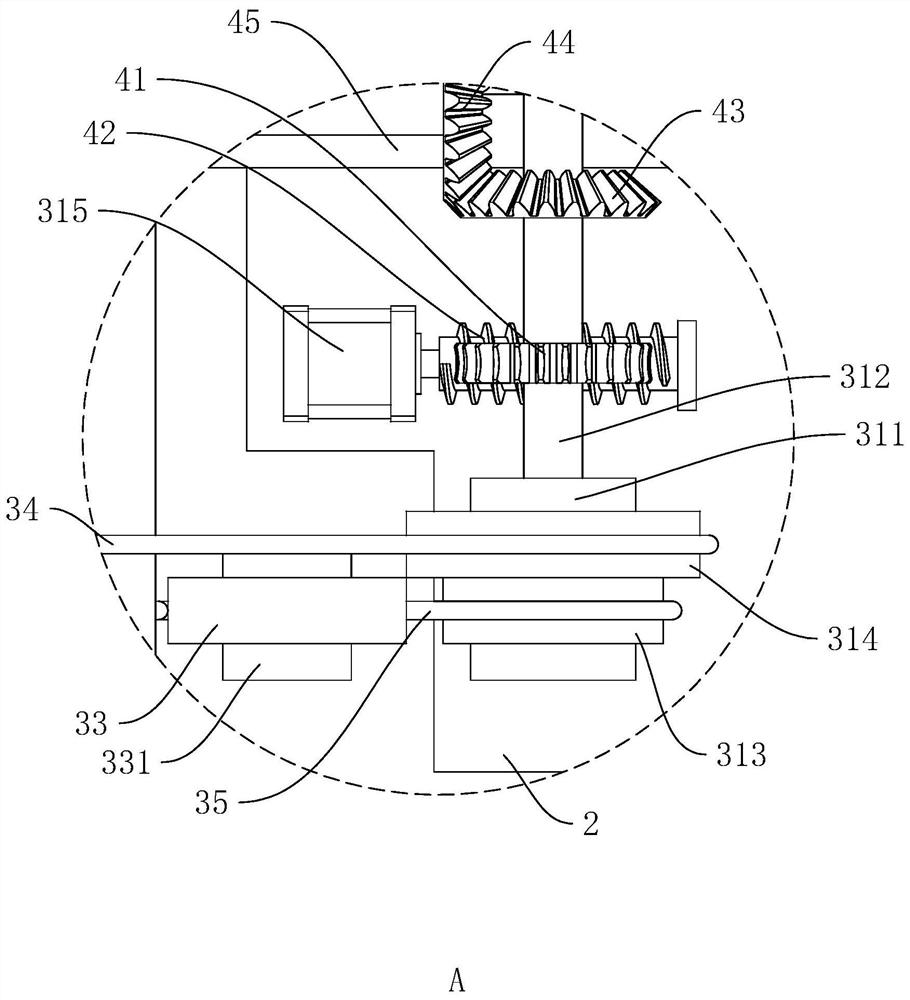

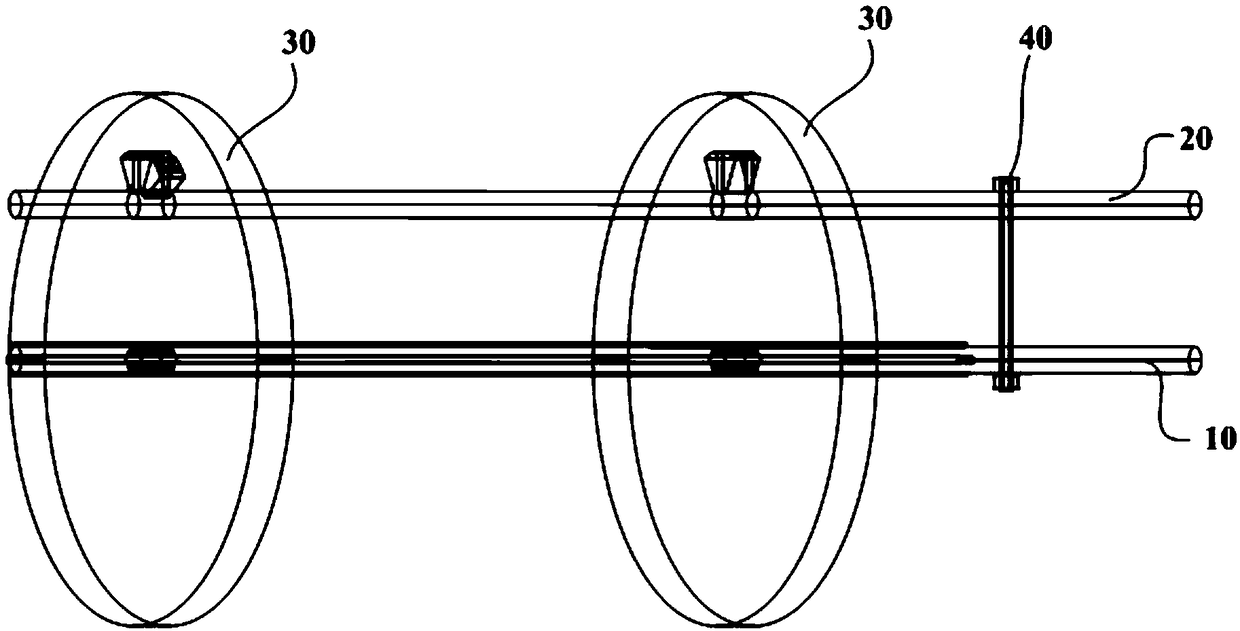

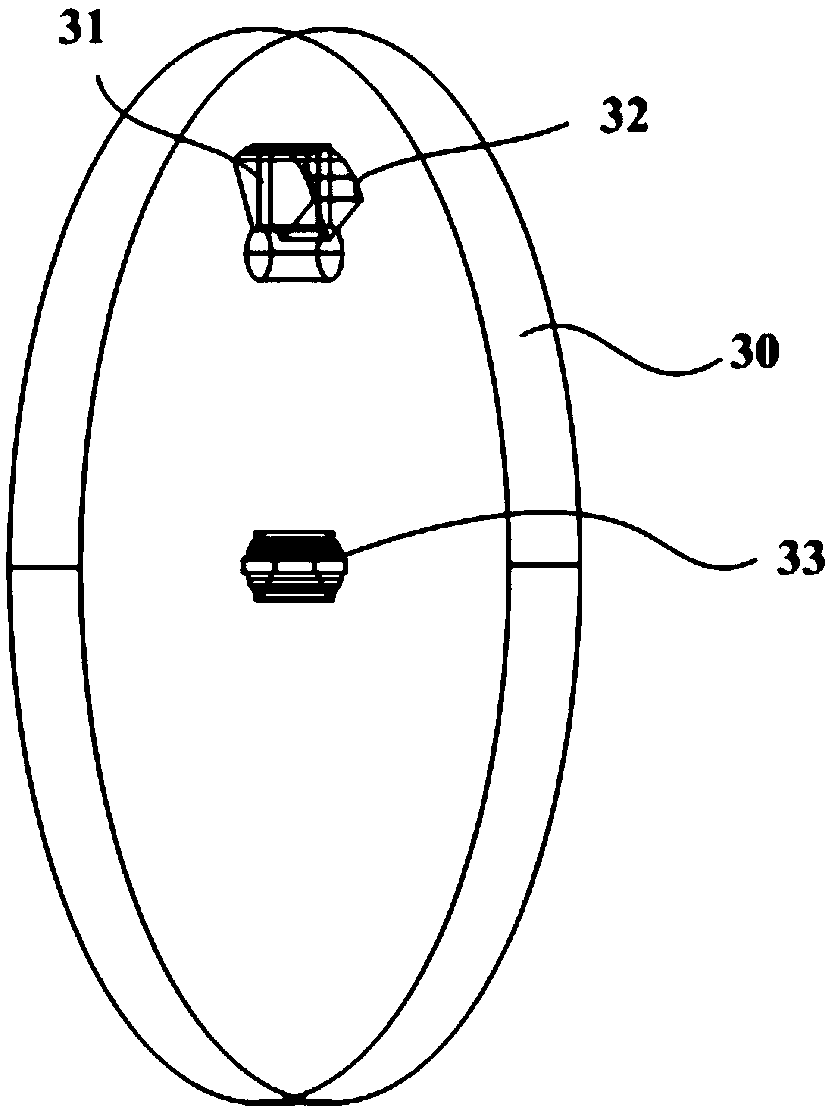

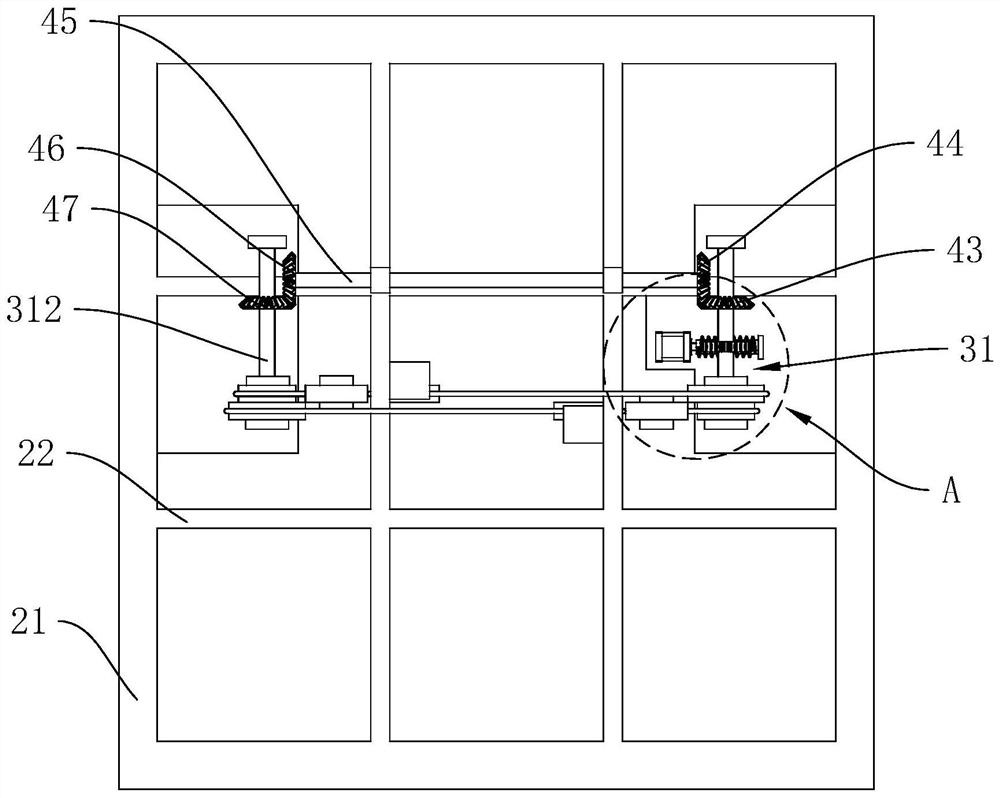

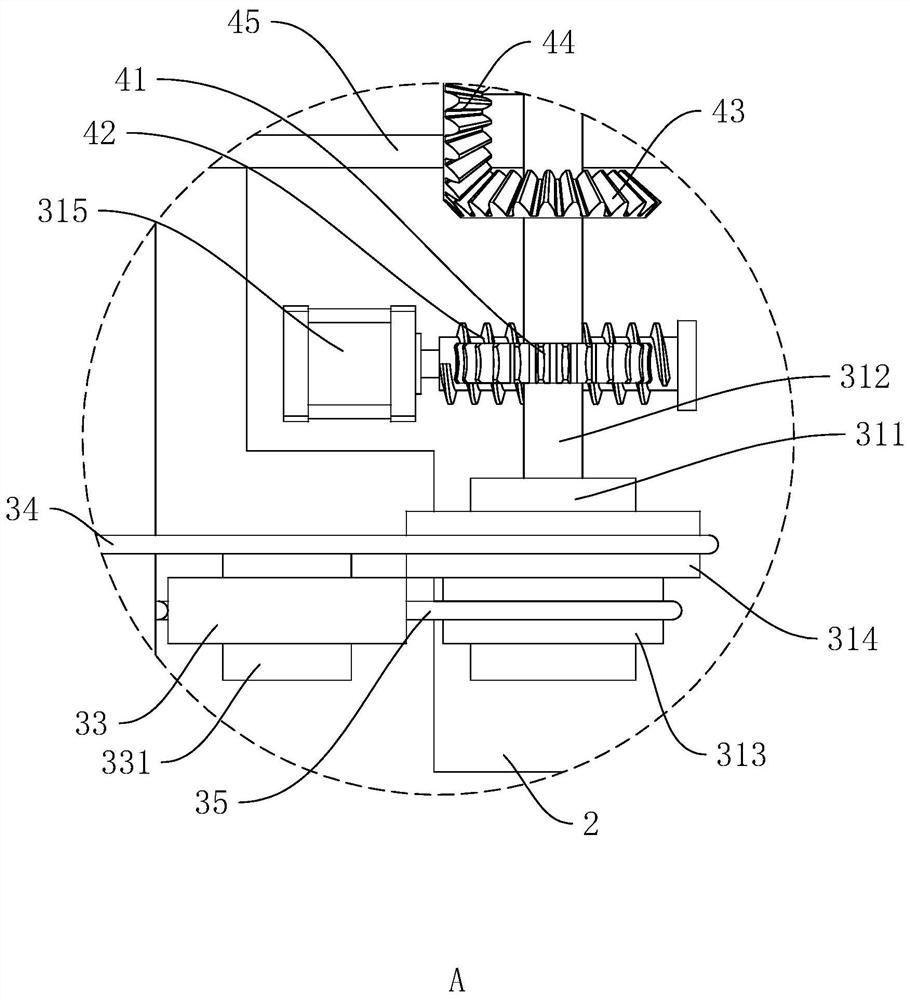

A device for automatically cleaning trash-stop nets in seawater intake channels of power stations

ActiveCN109371916BImprove cleaning and maintenance efficiencyReduce drowningArtificial water canalsPower stationNuclear power

The invention relates to the technical field of nuclear power station maintenance, and particularly discloses an automatic cleaning and trash blocking net device for a power station seawater water-intaking open channel. The device is arranged in the water channel, dirt is intercepted through a concentric-square-shaped trash blocking net, moreover, the dirt in the water channel is taken away from the water surface by rotating, when the dirt rotates along with the concentric-square-shaped trash blocking net to the position between a driving roller and a follow-up roller, high-pressure water mistsprayed out of a back flushing nozzle is used for washing dirt which is adhered to the outer surface of the concentric-square-shaped trash blocking net away from a net body, the dirt is scraped awaythrough a back flushing baffle to be further collected onto a dirt conveying belt, and the dirt is transported to a collecting box at the top of a bank slope through the dirt conveying belt. Accordingto the device, electric control automatic cleaning is adopted to replace manpower to automatically intercept and clear the dirt in the seawater water-intaking open channel of the power station, so that the clearing and maintaining efficiency is improved, and the problem that the influences of weather and people on the existing trash blocking and trash removing construction activities are generally large is solved.

Owner:HAINAN NUCLEAR POWER CO LTD

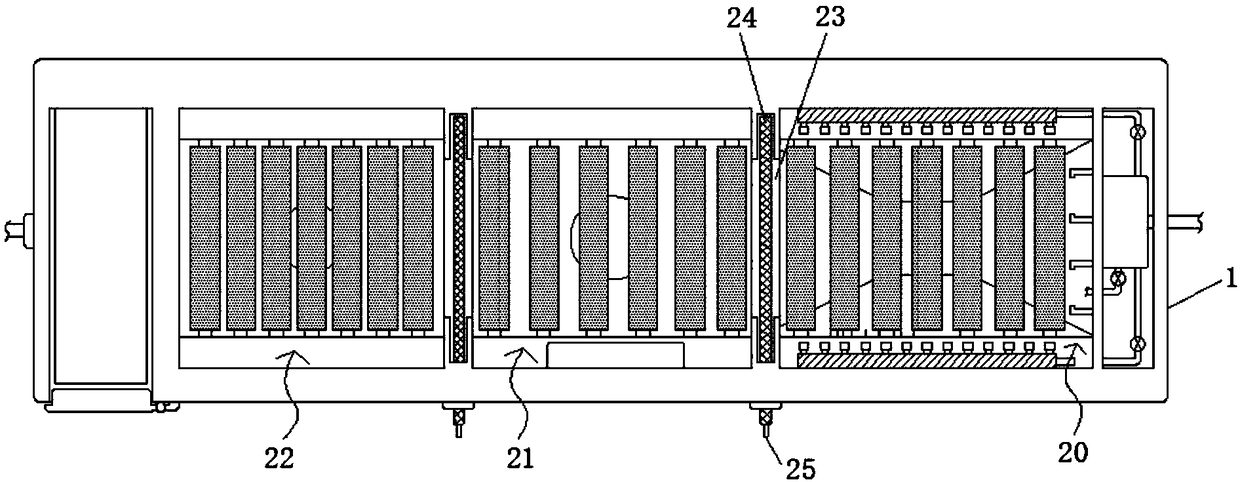

A heavy metal waste liquid treatment system for industrial production

ActiveCN109126246BImprove processing qualityLarge filter areaStationary filtering element filtersProcess engineeringTreatment system

The invention relates to the field of industrial production heavy metal waste liquid treatment systems and in particular discloses an industrial production heavy metal waste liquid treatment system which comprises a support rack, a support sleeve, an adjusting structure, two filtering structures, connecting tubes and two driving structures, wherein a driving structure communicated with the connecting tubes is arranged on the support rack; an adjusting structure for adjusting the angle of the support sleeve is arranged on a side wall of the support rack; the support sleeve is fixed on the adjusting structure; two filtering structures for filtering waste residues in a waste liquid are arranged at one end back to the adjusting structure, of the support sleeve. Two connecting tubes which are symmetrically arranged on the support rack of the system are connected with the filtering structures on the support sleeve through the driving structures, so that the filtering area of the waste residues is increased, and the anti-blocking property is improved; due to adoption of two filtering structures, positions of the filtering structures can be adjusted through the adjusting structure, furthermore the two filtering structures are alternatively arranged between the two driving structures, the filtering structures can be rapidly and conveniently mounted and dismounted, and the cleaning and maintenance efficiency of the filtering structures can be greatly improved.

Owner:阜阳全科智能技术设计有限公司

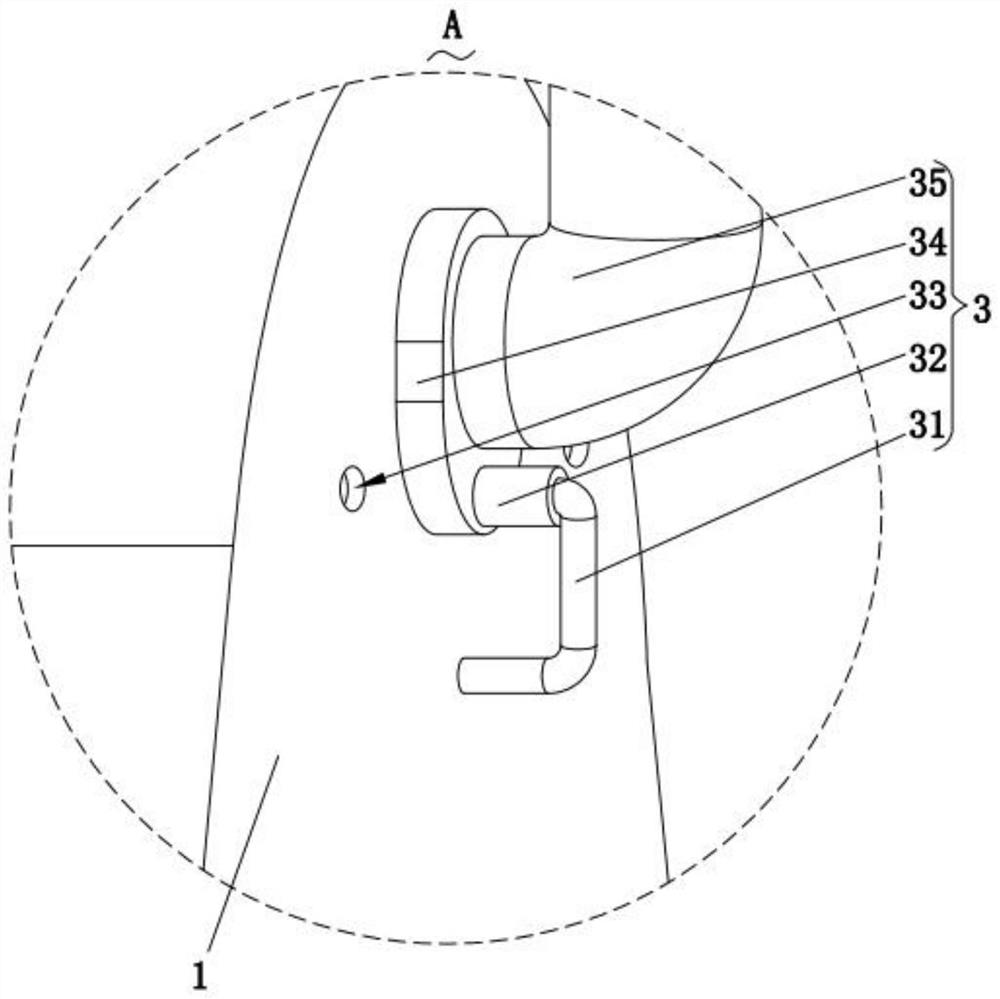

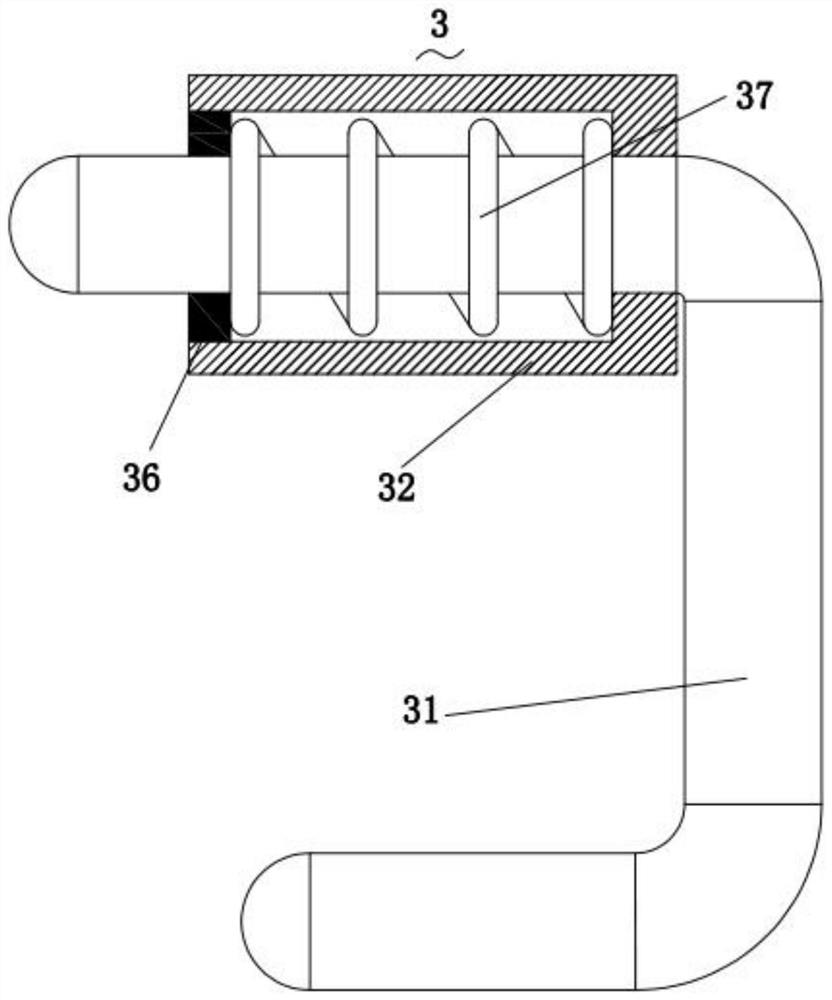

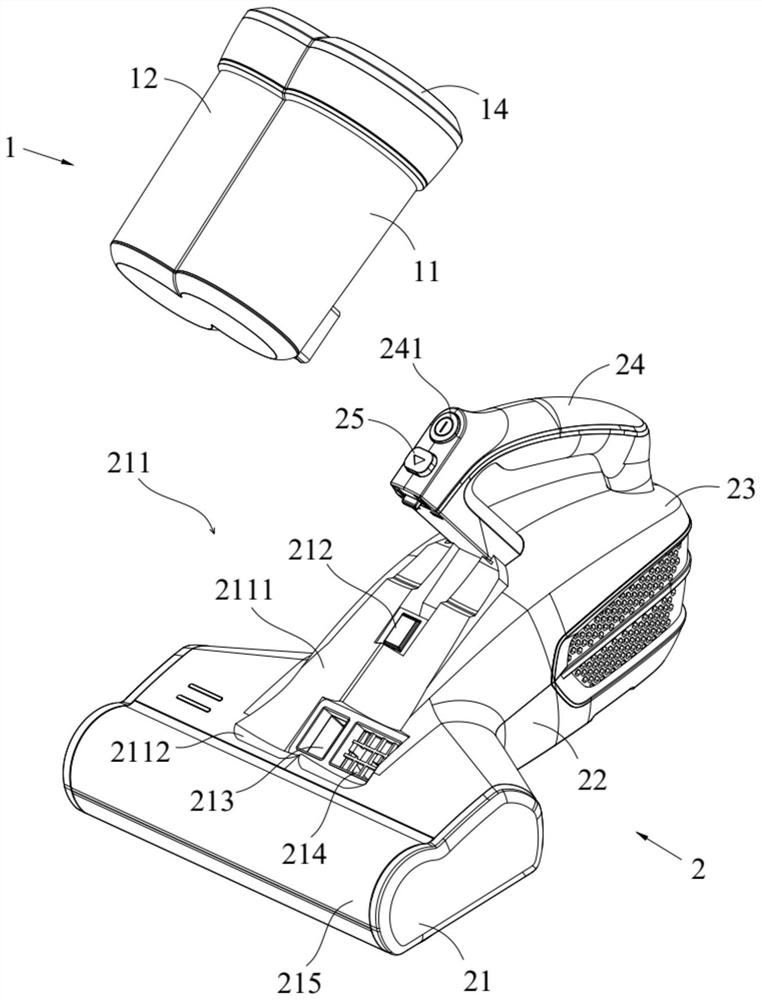

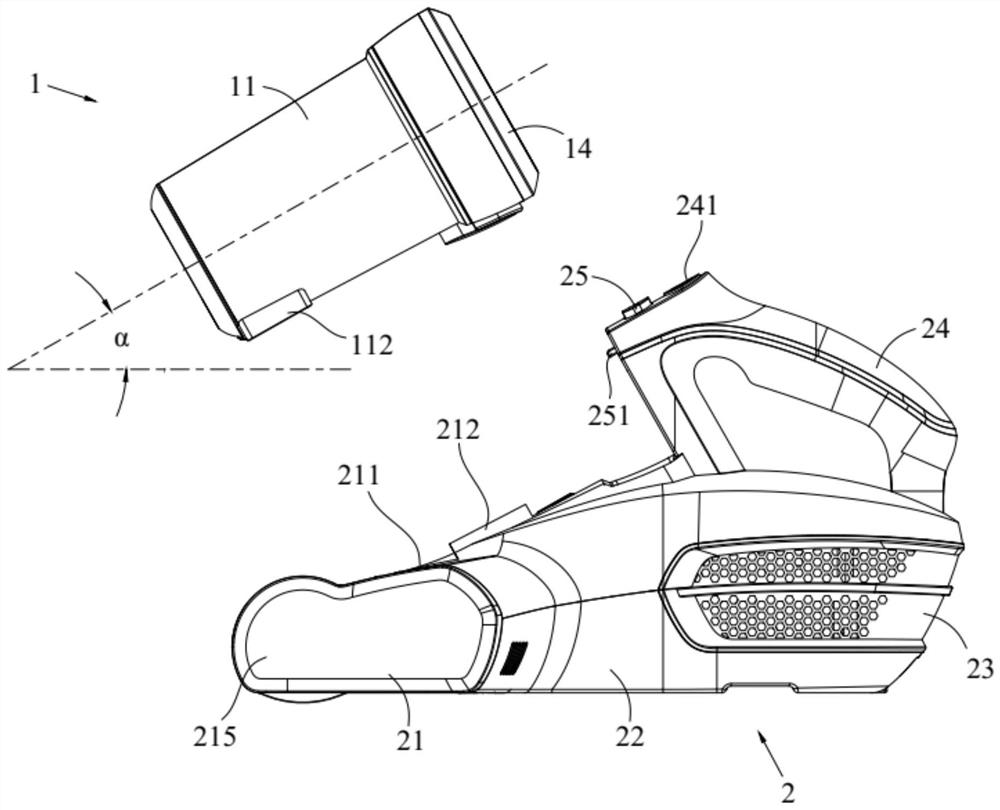

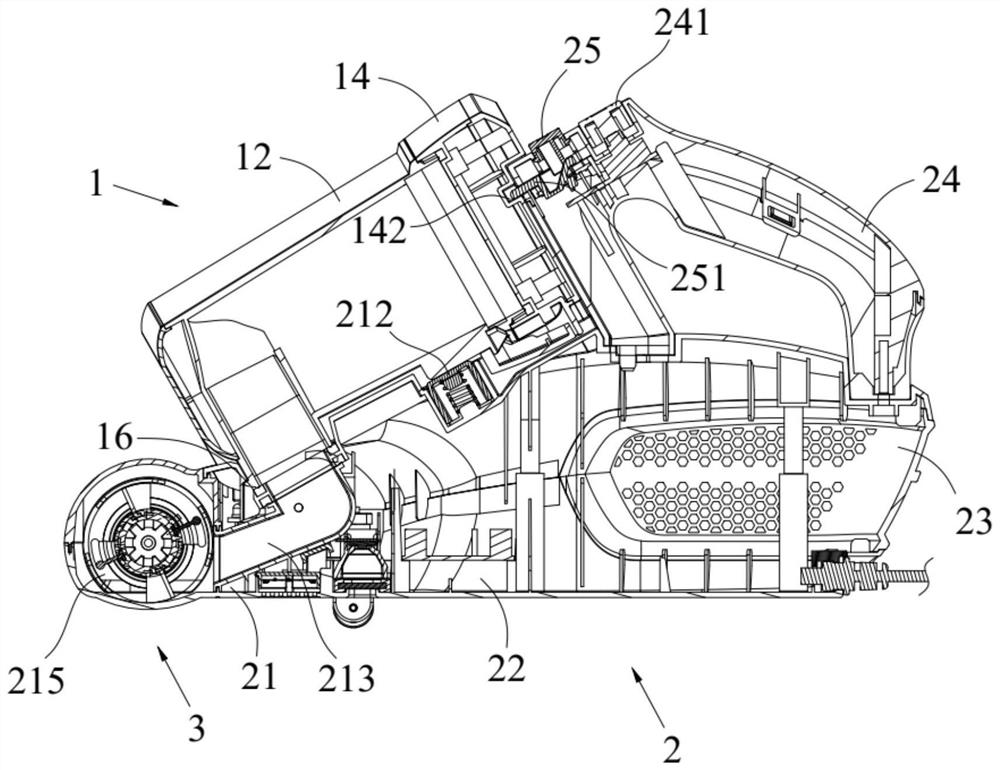

A mite remover

ActiveCN112155471BEasy to remove for cleaningImprove user experienceSuction filtersSuction nozzlesSuction forceMedicine

Owner:苏州睿克斯科技有限公司

Cigarette packaging system and operation method thereof

ActiveCN110451004AEasy to cleanImprove cleaning and maintenance efficiencyPackaging cigarettePackaging cigarsEngineeringPackaging machine

The invention relates to a cigarette packaging system and an operation method thereof for solving the problem that the cleaning efficiency is low. The cigarette packaging system comprises a packagingmachine internally provided with a photoelectric detector, a cleaning rod, a cleaning head and air supply equipment. The cleaning rod is internally provided with a cavity and arranged to stretch intothe packaging machine. The cleaning head is arranged at the first end of the cleaning rod, and the cleaning head is arranged to arrive at the position where the photoelectric detector is located whenthe cleaning rod stretches into the packaging machine. The cleaning head is provided with an air spraying hole communicating with the cavity. The air supply equipment communicates with the cavity of the cleaning rod. By means of the cigarette packaging system and the operation method thereof, the photoelectric detector arranged in a narrow area can be conveniently and rapidly cleaned, and the robot cleaning and maintaining efficiency is improved.

Owner:LONGYAN CIGARETTE FACTORY

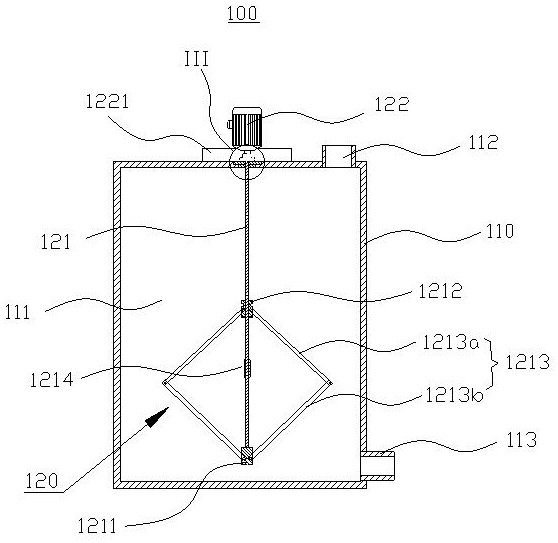

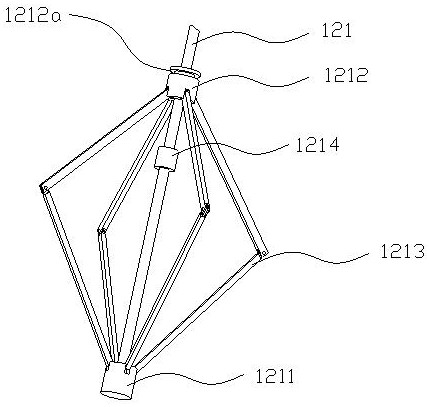

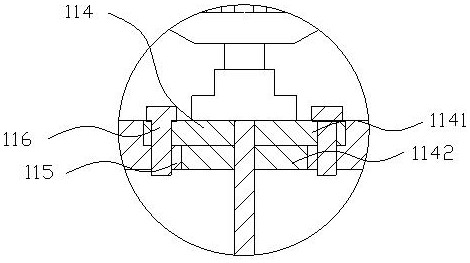

Dosing and stirring system

PendingCN113145002ASimple structureEasy to useRotary stirring mixersTransportation and packagingMechanical engineeringEngineering

The invention discloses a dosing and stirring system, which relates to the field of pharmaceutical equipment and comprises a tank body and a stirring device. The stirring device comprises a stirring shaft located in the stirring cavity, the stirring shaft is provided with a fixed part, a sliding part and stirring blades, the fixed part is located at the bottom end of the stirring shaft, and the sliding part slidably sleeves the stirring shaft and can slide in the length direction of the stirring shaft; the stirring blades comprise a long-strip-shaped first stirring blade and a long-strip-shaped second stirring blade, one end of the first stirring blade is hinged to the second stirring blade, and the other end of the first stirring blade is hinged to the sliding part; and one end of the second stirring blade is hinged with the first stirring blade, and the other end is hinged with the fixed part. By pulling the sliding part upwards, the stirring blades can be straightened, so that the stirring device can be conveniently taken out. And when the stirring device is placed, the fixed part naturally falls down, so that the stirring blades can be unfolded, and the stirring capacity is recovered. The dosing and stirring system is simple in structure and convenient to use. The cleaning and maintenance efficiency can be obviously improved.

Owner:重庆灏宁生物技术有限公司

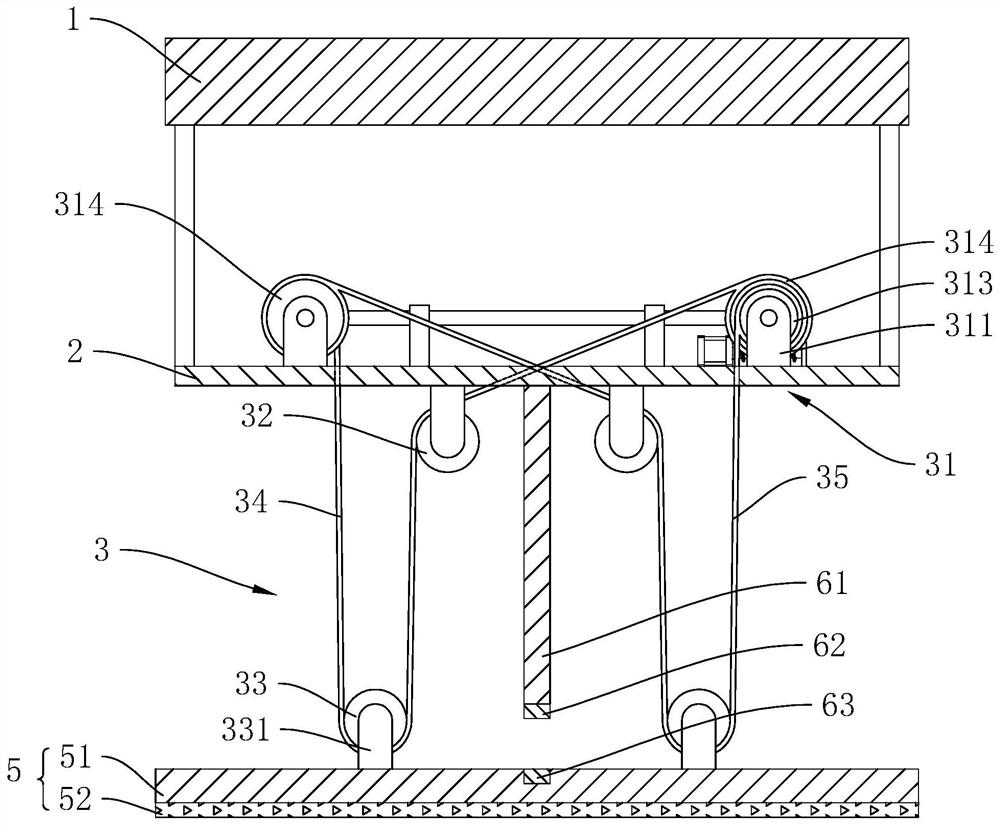

Embossment type suspended ceiling and process thereof

ActiveCN112538925AImprove cleaning efficiencyImprove maintenance efficiencyCeilingsPortable liftingDrive wheelKeel

The invention relates to an embossment type suspended ceiling. The embossment type suspended ceiling comprises a keel hanging bracket hung on the top of a building, lifting devices are arranged on thekeel hanging bracket, and embossment plates are hung on the lifting devices; each lifting device comprises a winding wheel set, a driven wheel and a hanging wheel, the winding wheel set is installedon the edge of the keel hanging bracket, the driven wheel is installed at the position, close to the center, of the keel hanging bracket, and the hanging wheel is installed on the side, facing the winding wheel set, of the embossment plates; the number of the lifting devices is two, a first rope and a second rope are in transmission connection between the two lifting devices, rotating directions of the two winding wheel sets are opposite, and the first rope is used for hoisting one hanging wheel; the two ends of the first rope are connected with the two winding wheel sets correspondingly, thesecond rope is used for hoisting the other hanging wheel, and the two ends of the second rope are connected with the two winding wheel sets correspondingly. According to the embossment type suspendedceiling, high-altitude work is avoided, the cleaning and maintaining efficiency of the embossment plates can be effectively improved, and the labor intensity of workers is greatly relieved.

Owner:广东正通博雅装饰工程有限公司

Preparation process of ventilated and breathable digital printing T-shirt

PendingCN114653144AImprove air qualityAvoid damageMechanical apparatusDispersed particle filtrationPolyesterTextile printer

The invention relates to the technical field of digital printing T-shirts, and discloses a preparation process of a ventilated and breathable digital printing T-shirt, which is characterized by comprising the following steps: preparing raw materials: preparing 120-150g of cotton fiber, 10-20g of spandex fiber, 20-40g of polyester fiber and 10-20g of viscose acetal fiber, preparing the T-shirt: preparing 120-150g of cotton fiber, 10-20g of spandex fiber, 20-40g of polyester fiber and 10-20g of viscose acetal fiber, and preparing the T-shirt by uniformly mixing the raw materials with the cotton fiber, the spandex fiber, the polyester fiber and the viscose acetal fiber; 20-40 g of polyester fibers and 10-20 g of viscose fibers are made into the T-shirt through a conventional technology, and pattern selection is conducted, specifically, a webpage is browsed on a computer, a pattern which finally needs to be printed is selected, then the pattern is edited, and the final pattern is made. According to the preparation process of the ventilated and breathable digital printing T-shirt, by arranging the air purification device, peculiar smell generated during ink jetting can be filtered and purified, in this way, the process has the peculiar smell removal function, the generated peculiar smell can be adsorbed and filtered when ink jetting is conducted on the T-shirt, the air quality of a workshop is improved, and the production cost is reduced. And the damage to the body health of workers is reduced.

Owner:福建蓝帝狮校园服饰有限公司

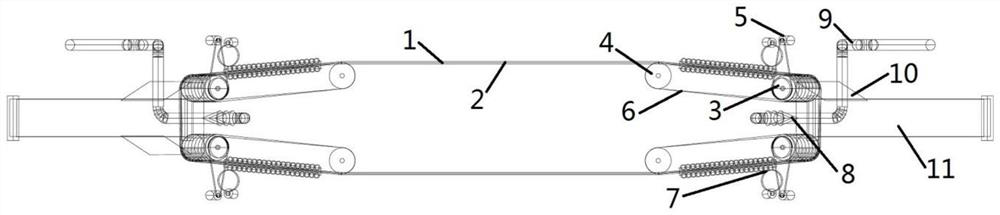

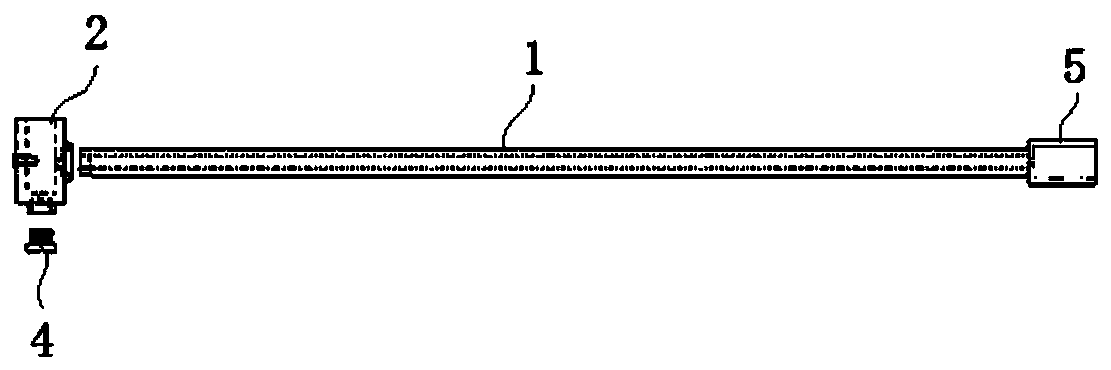

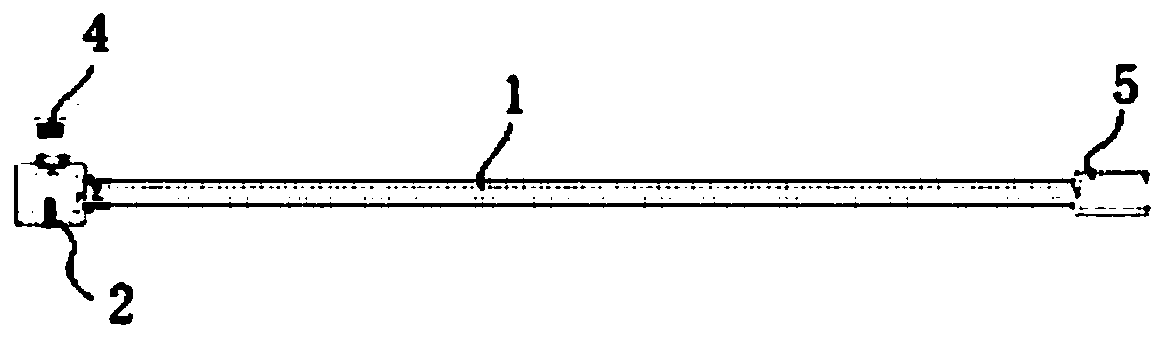

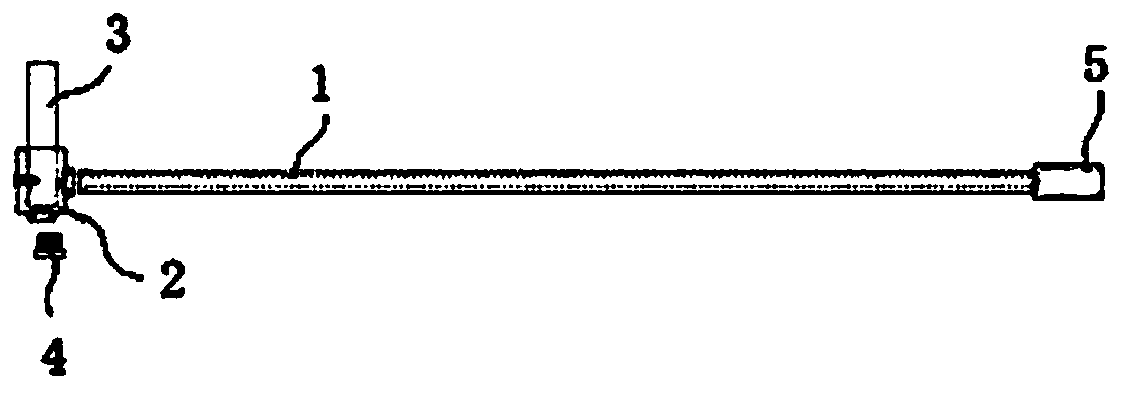

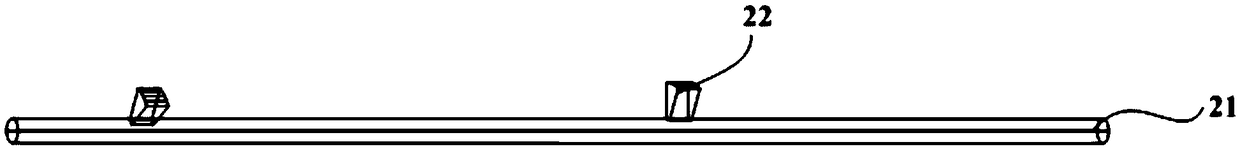

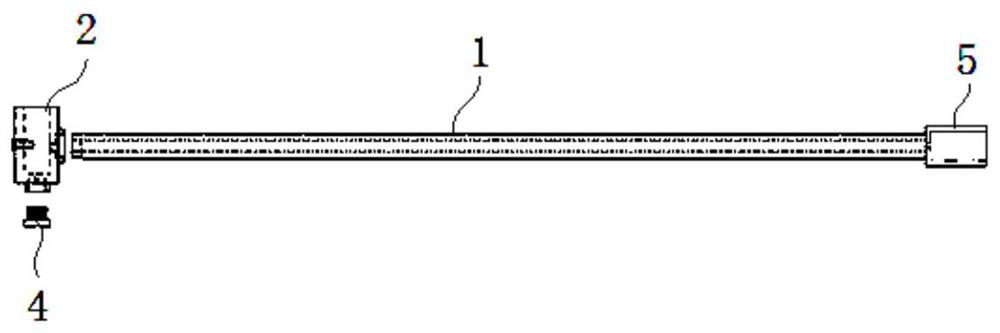

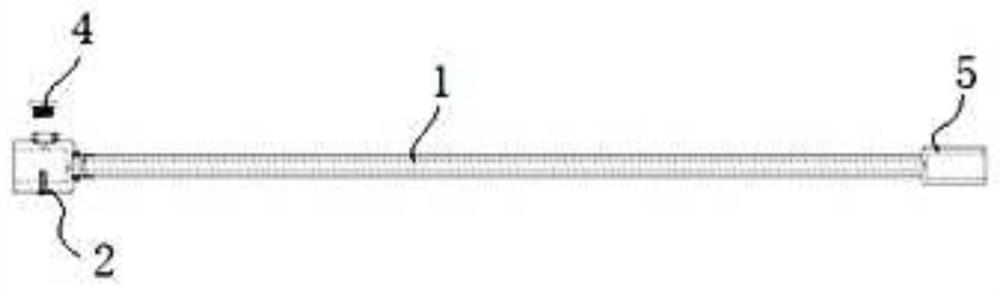

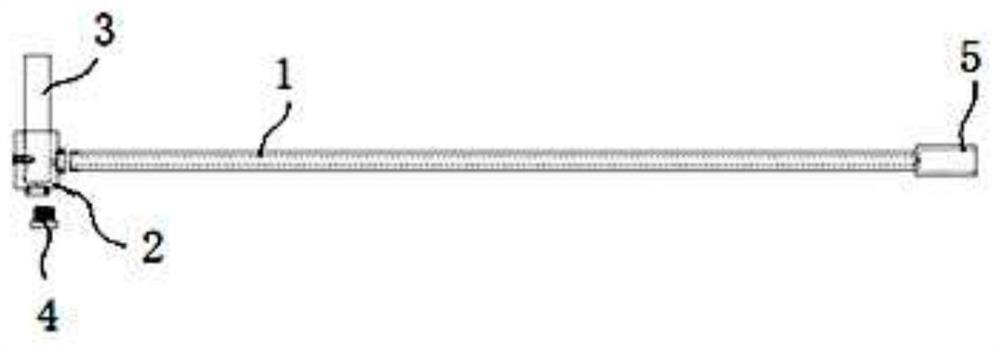

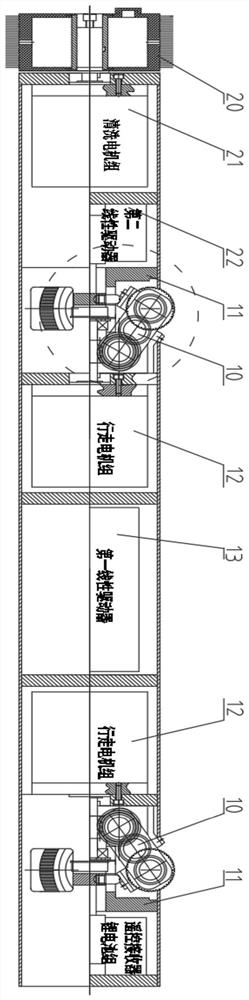

Substrate transfer device, substrate transfer device, and disassembly method thereof

ActiveCN106976693BReduce the difficulty of operationImprove cleaning and maintenance efficiencyMechanical conveyorsLocking mechanismEngineering

The invention relates to the technical field of substrate conveying and discloses a substrate conveying device, substrate conveying equipment and a detaching method thereof. The substrate conveying device comprises a plurality of substrate conveying units. Each substrate conveying unit comprises a rotating shaft, a fixed shaft, a plurality of rollers arranged on the rotating shaft and the fixed shaft in a sleeving mode and a locking mechanism. The rotating shafts are arranged at the centers of the multiple rollers which can rotate around the rotating shafts and can move in the length directions of the rotating shafts. Each fixed shaft comprises a fixed shaft body and a plurality of positioning protruding blocks protruding out of the fixed shaft body. The position protruding blocks and the rollers are arranged in one to one correspondence. The fixed shafts are arranged between the centers and the edges of the multiple rollers. The rollers are provided with avoiding positions avoiding the positioning protruding blocks and limiting grooves communicating with the avoiding positions. The positioning protruding blocks rotate to the avoiding positions, arranged correspondingly to the positioning protruding blocks, of the rollers, and then can be limited in the limiting grooves communicating with the avoiding positions. The locking structures are used for enabling the rotating shafts and the fixed shafts to keep relative fixing.

Owner:BOE TECH GRP CO LTD +1

Cigarette packaging system and method of operation thereof

ActiveCN110451004BEasy to cleanImprove cleaning and maintenance efficiencyPackaging cigarettePackaging cigarsPhotodetectorGas supply

The invention relates to a cigarette packaging system and its operating method, which are used to alleviate the problem of low cleaning efficiency. Among them, the cigarette packaging system includes: a packaging machine, which is provided with a photoelectric detector; a cleaning rod, which is provided with a cavity, and the cleaning rod is configured to extend into the packaging machine; a cleaning head is located on the The first end of the cleaning rod, the cleaning head is configured to reach the position of the photoelectric detector when the cleaning rod extends into the packaging machine; the cleaning head is provided with an air jet hole, the an air jet hole communicates with the cavity; and an air supply device communicates with the cavity of the cleaning rod. The invention can conveniently and quickly clean the photoelectric detector installed in a narrow area, and improves the cleaning and maintenance efficiency of the machine.

Owner:LONGYAN CIGARETTE FACTORY

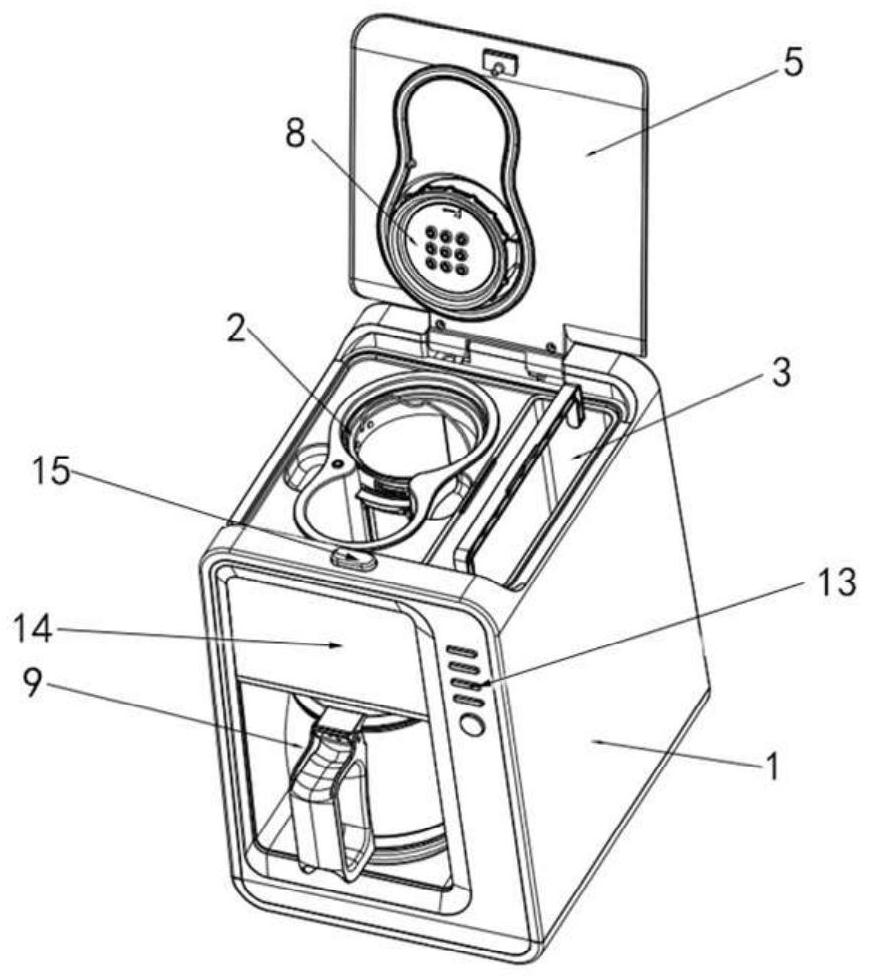

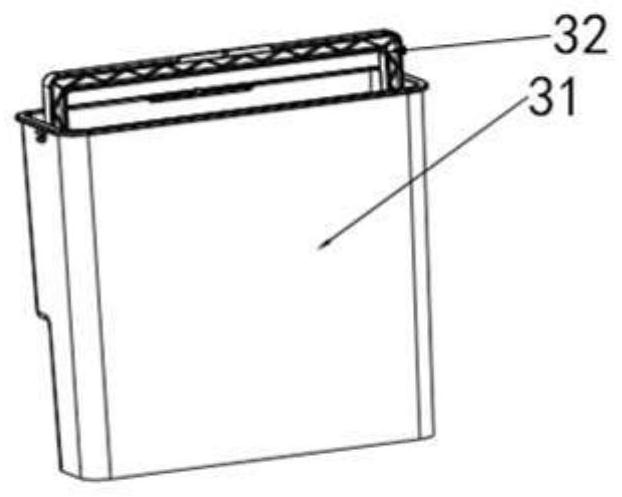

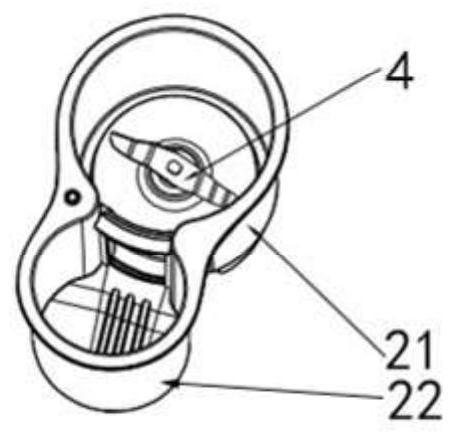

Bean grinding coffee machine

PendingCN112773194AEasy to disassembleImprove cleaning and maintenance efficiencyBeverage vesselsGround-beanMechanical engineering

The embodiment of the invention discloses a bean grinding coffee machine. The bean grinding coffee machine comprises a machine body, a brewing chamber and a water tank, the machine body is provided with a first containing cavity and a second containing cavity, the top of the first containing cavity and the top of the second containing cavity are open, the first containing cavity and the second containing cavity are arranged side by side, the brewing chamber is detachably installed in the first containing cavity, the water tank is detachably installed in the second containing cavity, and the volume ratio of the brewing chamber to the water tank ranges from 1: 102 to 1: 17. According to the embodiment of the invention, the brewing chamber can be detached from the machine body due to the fact that the brewing chamber is detachably mounted in the first accommodating cavity, the purpose of convenient detachment is achieved, the cleaning and maintenance efficiency is improved, and meanwhile, the water tank can be detached from the machine body due to the fact that the water tank is detachably mounted in the second accommodating cavity. The purpose of convenient disassembly is achieved, and the cleaning and maintenance efficiency is improved.

Owner:青岛海氏烘焙电器有限公司

Direct-acting soft friction testing apparatus

InactiveCN102519867BChange the relative sliding speedImprove cleaning and maintenance efficiencyUsing mechanical meansMaterial analysisEngineeringFriction force

The invention relates to a direct-acting soft friction testing apparatus comprising a supporting stage. A lower sample fixing rack is arranged on the upper part of the supporting stage, and is connected with a driving mechanism. Under the driving of the driving mechanism, the fixing rack can move linearly in a plane. An upper sample assembly is arranged on the upper part of the lower sample fixing rack, and is connected to a loading mechanism which can apply a pressure downwards. A friction force detecting mechanism is connected with the upper sample assembly. Two samples with different elastic modulus are respectively fixed in the upper sample assembly and on the lower sample fixing rack. With the loading mechanism, the upper sample is pressed against the lower sample. The apparatus is advantaged in simple structure. Various testing parameters can be easily changed. When the lower sample is manufactured by using a transparent material, an elastic material surface deformation image and a residual liquid distribution image on a contact area can be acquired in real-time. Therefore, a solution is provided for optimizing selection of soft friction materials in complicated environments.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

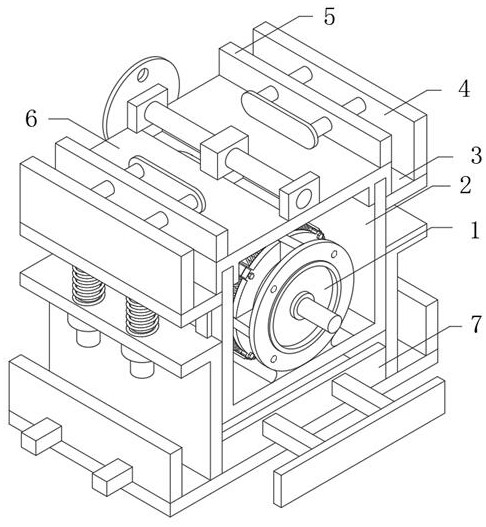

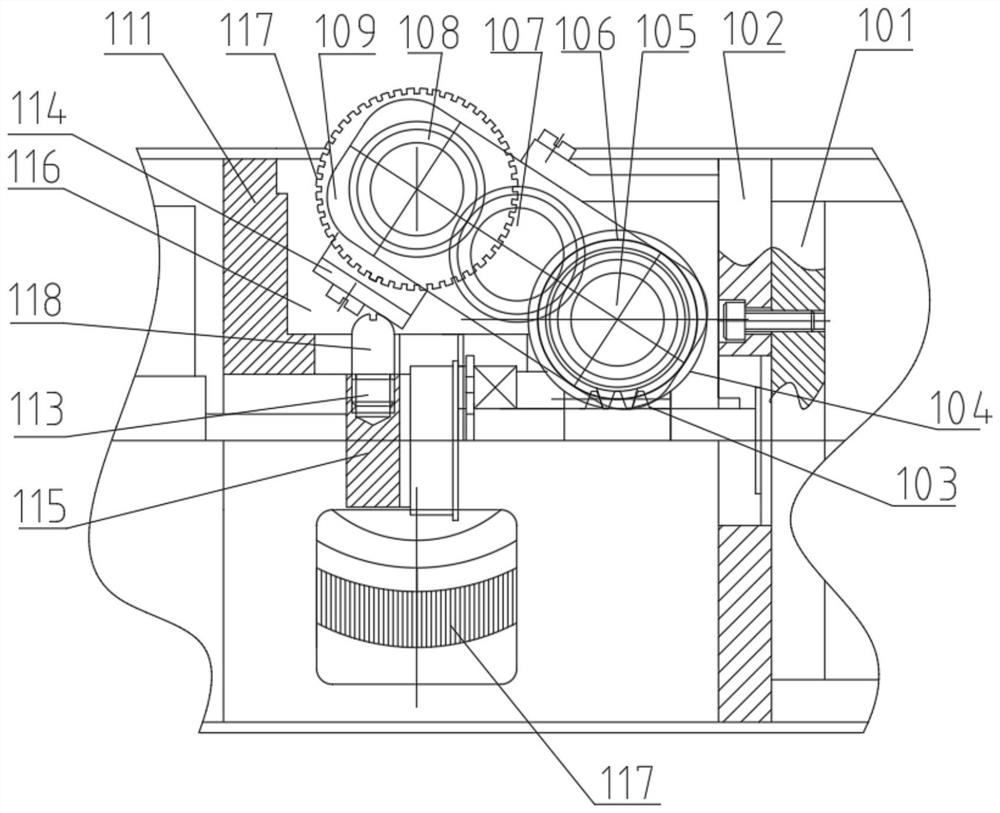

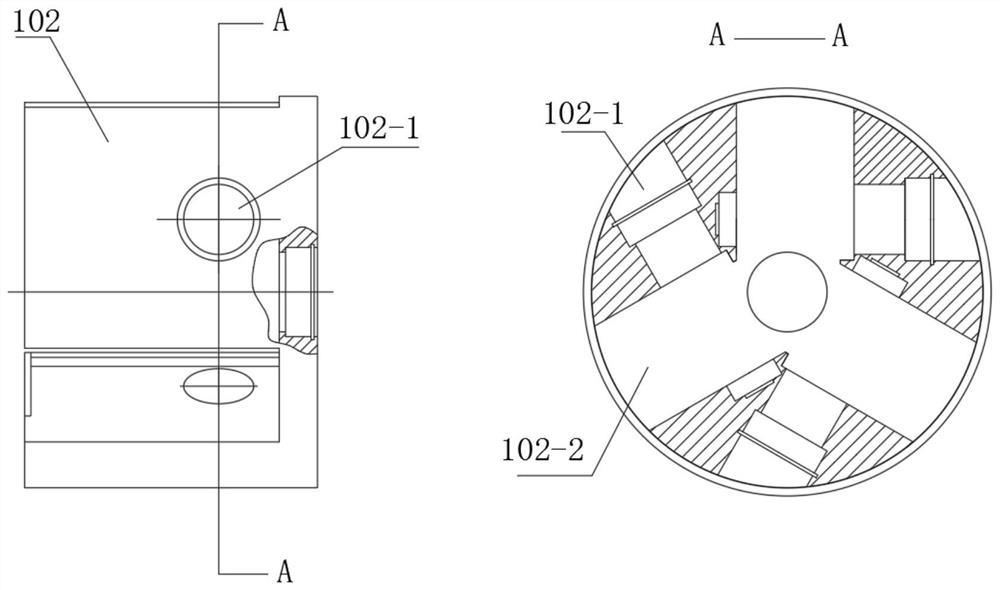

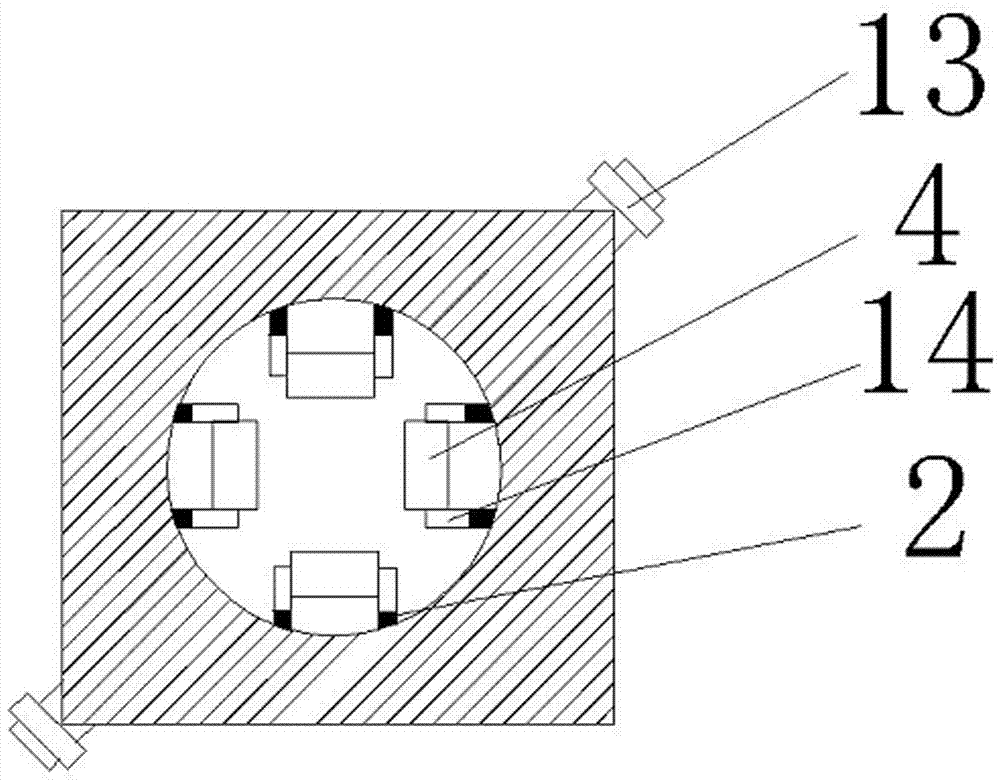

Motor unit convenient to clean and maintain and maintenance method thereof

PendingCN112713700AEasy to disassembleEasy maintenanceManufacturing dynamo-electric machinesCleaning using toolsGear driveElectric machine

The invention discloses a motor unit convenient to clean and maintain and a maintenance method thereof. The motor unit comprises a motor unit body, wherein a first positioning frame is fixedly arranged at the bottom end of the motor unit body, first sliding strips are fixedly arranged at the two ends of the two sides of the first positioning frame correspondingly, and first sliding grooves are slidably formed in the four first sliding strips correspondingly; by pulling a baffle, the baffle drives a second rack to be engaged with the top end of the outer wall of a gear, the gear rotates, one end of the outer wall of the second rack is connected with one end of one side of a first positioning plate in a penetrating mode, and the two ends of the bottom of the outer wall of the gear drive two first racks to rotate; bottom ends of the two first racks slide with first sliding grooves formed in the two ends of the bottom of the inner wall of the second positioning frame correspondingly to drive the two positioning frames to contract inwards, so the second positioning frame is separated from the external environment, the motor unit is disassembled conveniently, the motor unit is convenient to overhaul, and maintenance and detection efficiency of the motor unit is improved.

Owner:南通硕兴机电有限公司

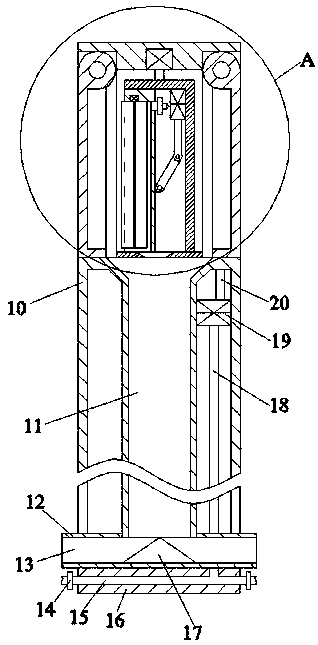

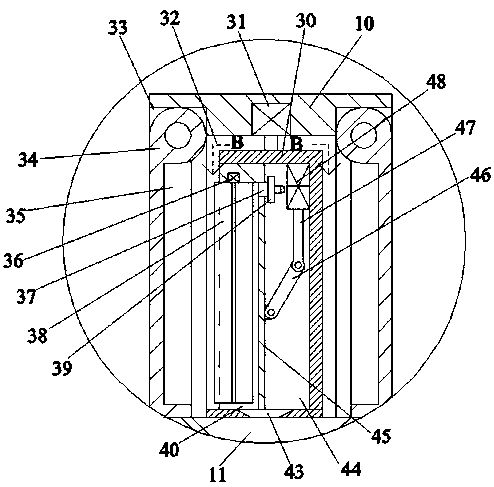

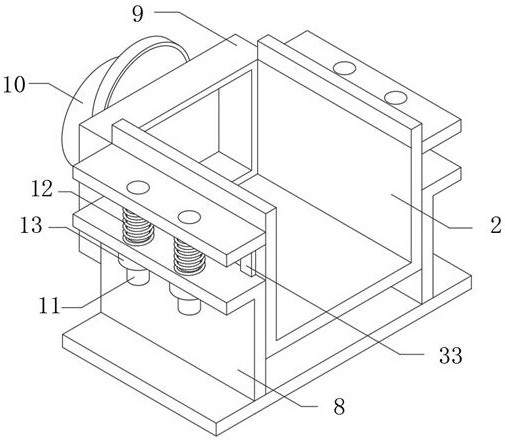

A barrel cleaning device

ActiveCN110617733BGuaranteed normal operationGuaranteed smooth progressWeapon cleaningStructural engineeringGun barrel

A gun bore cleaning device relates to the cleaning field of weapons, including a cleaning part and a driving part, the driving part and the cleaning part are coaxially arranged and fixed to each other, and a worm gear transmission is arranged in the driving part, and a device with a tension force is provided. The spring device is used to increase the convenience and practicability of the gun bore cleaning equipment, and the rubber wheels are arranged in a reasonable circumferential direction to further ensure the stability of the gun bore cleaning equipment in the gun bore.

Owner:湖北才韬科教仪器有限公司

Cleaning and maintenance device for mechanical parts

InactiveCN108993978AClean upPrevent rustDrying gas arrangementsCleaning using toolsExhaust pipeReliability engineering

The invention discloses a cleaning and maintenance device for mechanical parts. The cleaning and maintenance device comprises a cleaning and maintenance cabinet. Supporting legs are fixedly connectedto the bottom of the cleaning and maintenance cabinet. The cleaning and maintenance cabinet comprises a cleaning section, a drying section and an oiling section. A drain pipe is fixedly connected to the bottom of the cleaning section. An exhaust pipe is fixedly connected to the bottom of the drying section. A blow-off pipe is fixedly connected to the bottom of the oiling section. Though the arrangement of the cleaning and maintenance cabinet, the cleaning section, the drying section and the oiling section, the cleaning and maintenance device can achieve manual cleaning and auxiliary manual cleaning of the mechanical parts automatically, and the mechanical parts can be cleaned more completely; the mechanical parts are dried with hot air after being cleaned so as to be prevented from be rusted; the mechanical parts are oiled after being dried, so that when used again, the service life of the mechanical parts is prolonged, and the safety performance of the mechanical parts is improved; and meanwhile, by adoption of the cleaning and maintenance device, the labor cost can be reduced, the cleaning and maintenance effect of the mechanical parts is improved, and accordingly, the use requirements of people can be met.

Owner:吴帅英

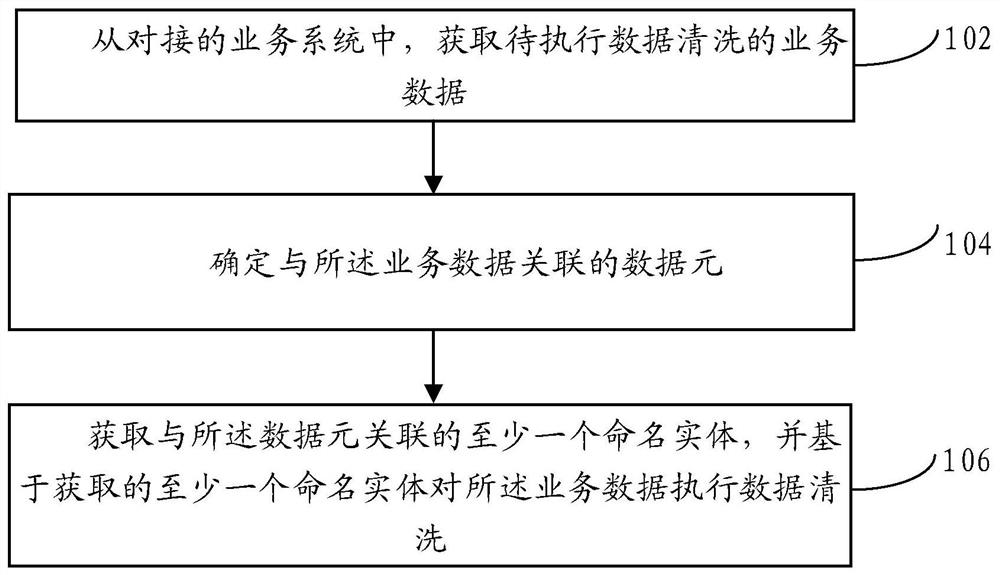

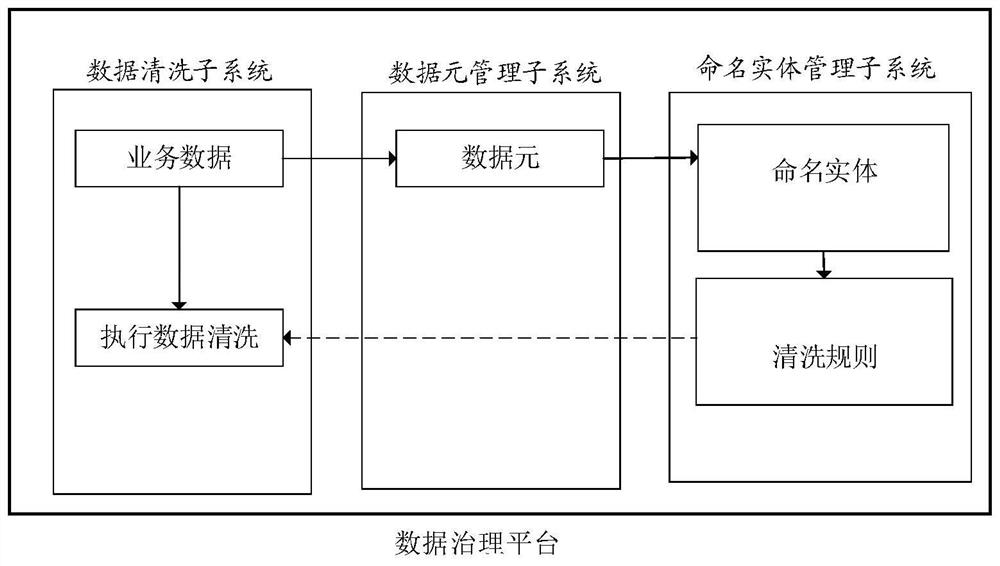

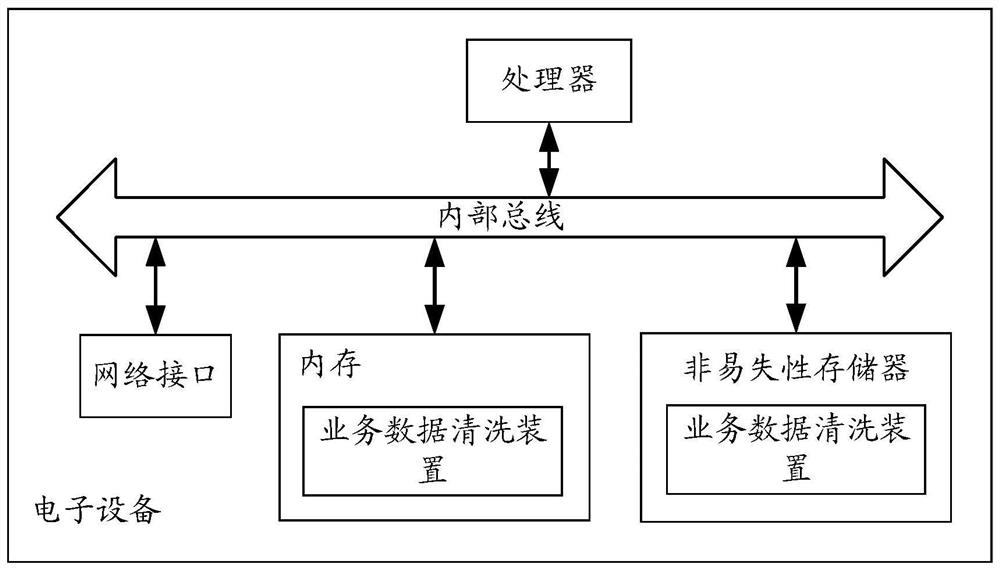

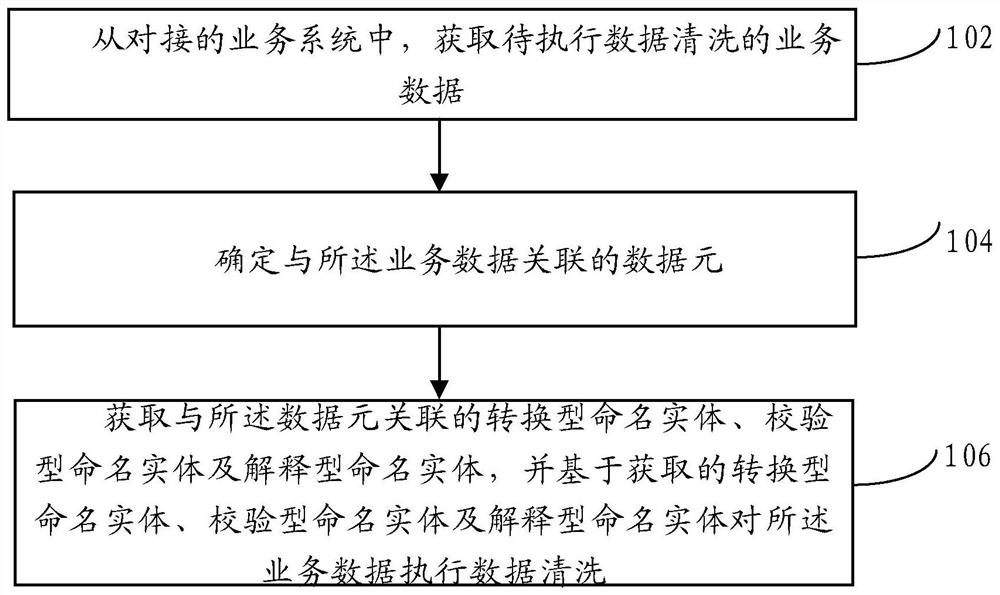

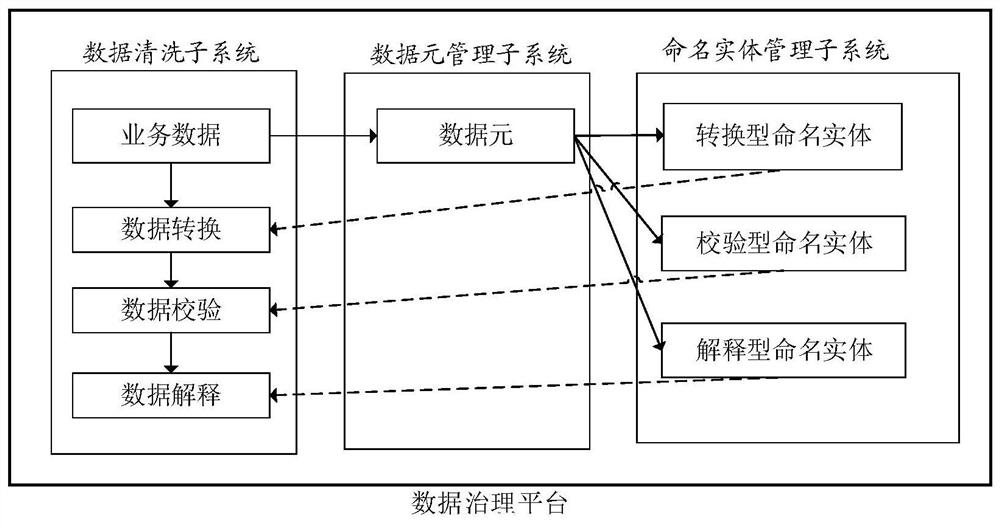

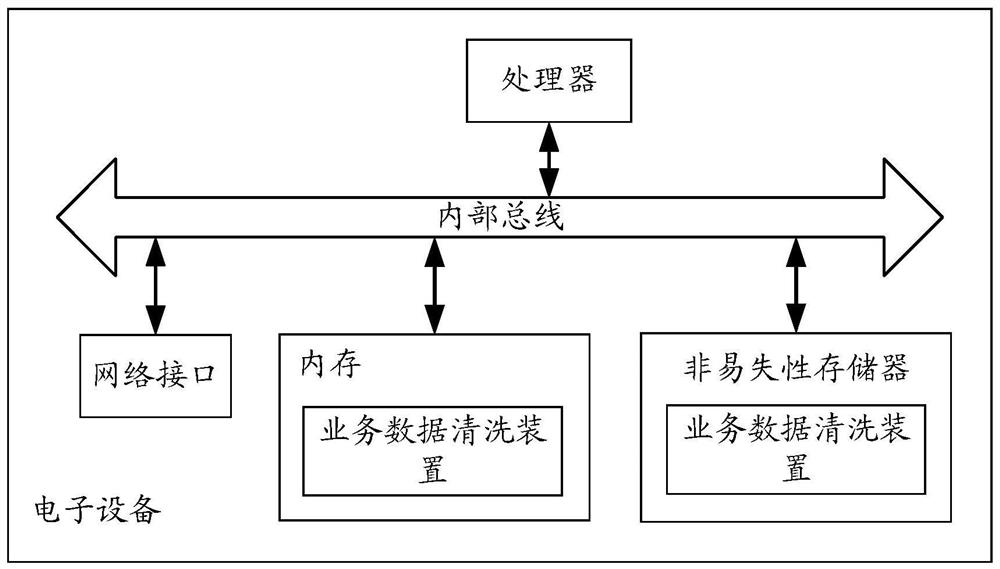

Service data cleaning method, device and electronic equipment

PendingCN112256689AImprove cleaning and maintenance efficiencyPromote accumulationDigital data information retrievalSpecial data processing applicationsData elementData mining

The invention discloses a service data cleaning method, a device, electronic equipment and a machine readable storage medium. The method comprises the steps of obtaining service data to be subjected to data cleaning from a butted service system; determining a data element associated with the service data; and obtaining at least one named entity associated with the data element, and performing datacleaning on the service data based on the obtained at least one named entity. Data cleaning is carried out based on the named entity which is what you see is what you get, tedious data cleaning configuration of a user is avoided, data cleaning maintenance efficiency is improved, and accumulation and sharing utilization of the named entity are facilitated.

Owner:HANGZHOU DT DREAM TECH

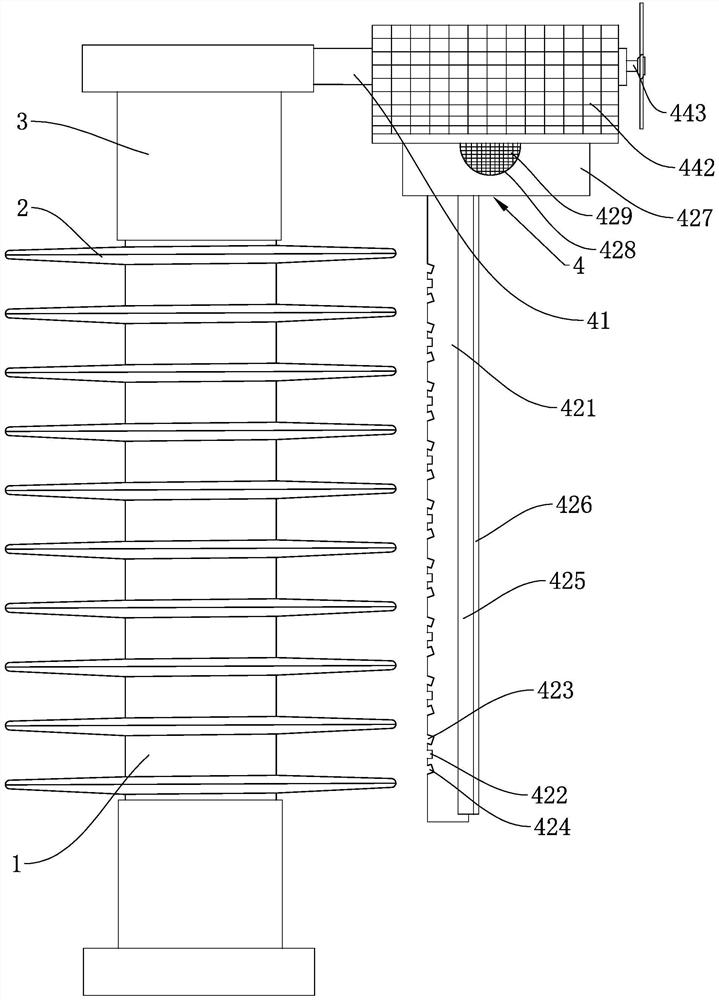

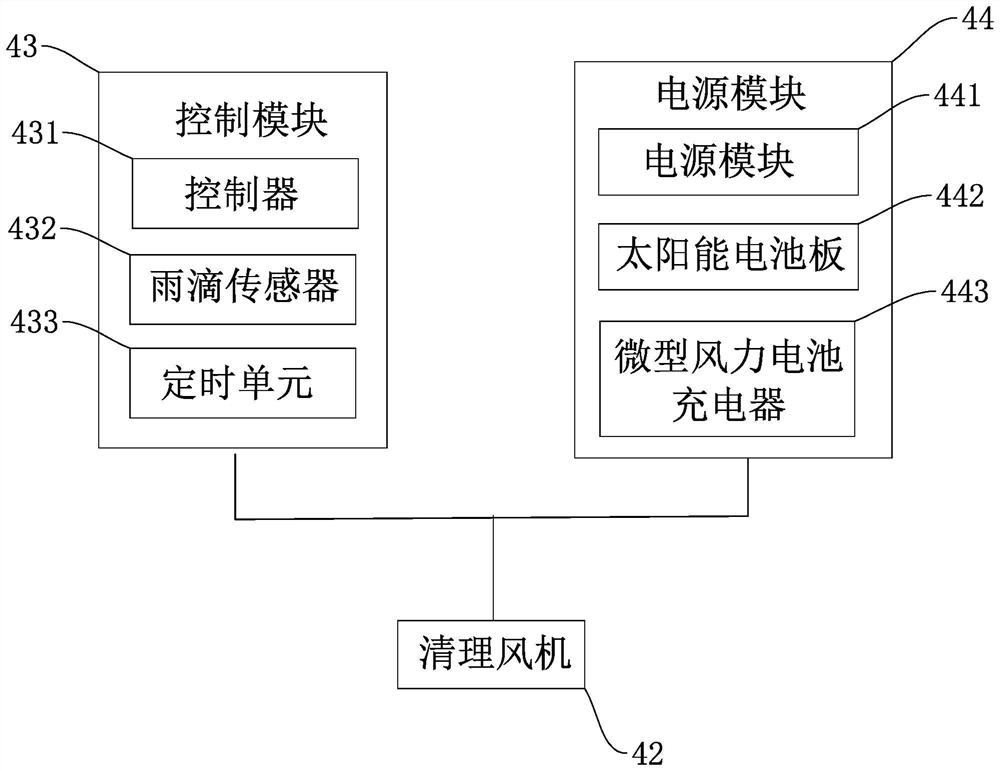

Antifouling self-cleaning column type composite insulator

PendingCN114464383AAchieve antifouling self-cleaning effectExtended service lifeDispersed particle filtrationInsulatorsComposite insulatorsStructural engineering

The invention relates to an antifouling self-cleaning column type composite insulator which comprises an insulating core, a plurality of umbrella skirts arranged on the insulating core in a sleeving mode and connecting hardware fittings installed at the two ends of the insulating core, and the hardware fitting at the top of the insulating core is connected with a cleaning mechanism used for cleaning the umbrella skirts. The cleaning mechanism comprises a base, a cleaning fan, a control module and a power module; an air outlet of the cleaning fan is connected with a cleaning air pipe, the cleaning air pipe is arranged in the length direction of the insulating core, the end, away from the cleaning fan, of the cleaning air pipe is closed, and a plurality of cleaning air openings are formed in the outer side wall of the cleaning air pipe in the length direction of the cleaning air pipe and all face the umbrella skirt; the control module comprises a controller and a raindrop sensor, the raindrop sensor is installed on the top of the base, and the raindrop sensor, the cleaning fan and the power module are all connected with the controller. The composite insulator can be conveniently and rapidly cleaned and maintained, and the service life of the composite insulator is effectively prolonged.

Owner:徐剑刚

A heavy metal waste liquid treatment process

ActiveCN109133485BHEPA filterImprove processing efficiencyWater contaminantsTreatment involving filtrationEnvironmental engineeringToxic industrial waste

The invention relates to the technical field of industrial waste liquid treatment technology, specifically a heavy metal waste liquid treatment process, which includes the following steps: passing the heavy metal waste liquid into a filter box, and filtering the large particles in the metal waste liquid through the filter box Filter; the filter box is installed above the waste liquid treatment equipment, and the filter box and the waste liquid treatment equipment are connected by an electromagnet; the filtered waste liquid is passed into the waste liquid treatment equipment; in the waste liquid treatment Two electromagnet disks are installed symmetrically on the slope of the support sleeve of the equipment; the lower end of the electromagnet disk is fixedly connected to the upper end of the iron rod, the lower end of the iron rod is installed with a net bag, and the lower end of the iron rod extends into the cavity of the waste liquid treatment equipment; when the waste liquid When the treatment equipment adjusts the position of the filter structure, the net bag is also removed during the process of dismantling the filter structure, and the cleaning is performed at the same time, thereby improving the efficiency of the waste liquid treatment equipment; the invention realizes the efficient removal of heavy metal particles.

Owner:江苏邦腾环保技术开发有限公司

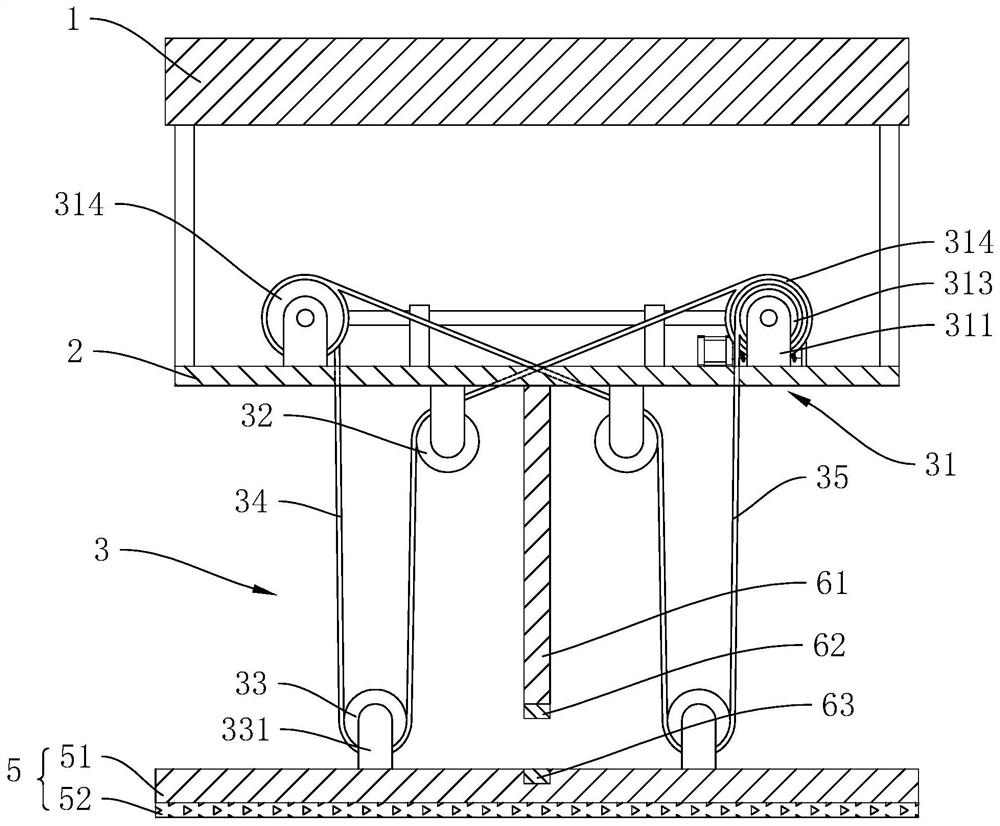

A kind of embossed ceiling and its technology

ActiveCN112538925BImprove cleaning and maintenance efficiencyReduce labor intensityCeilingsPortable liftingDrive wheelKeel

The application relates to an embossed ceiling, which includes a keel hanger hoisted on the top of a building, a lifting device is arranged on the keel hanger, a relief plate is hoisted on the lifting device, and the lifting device includes a winding wheel set, a driven wheel and a hoisting device. The winding wheel set is installed at the edge of the keel hanger, the driven wheel is installed at the center of the keel hanger, the hoisting wheel is installed on the side of the embossed plate facing the winding wheel set, and the lifting devices are set to two groups, two groups A first rope and a second rope are drivingly connected between the lifting devices. The rotation directions of the two rewinding wheel groups are opposite. The first rope is used to hoist one of the hoisting wheels. The second rope is used for hoisting another hoisting wheel, and the two ends of the second rope are respectively connected with two winding wheel sets. The proposed solution avoids high-altitude operation, can effectively improve the cleaning and maintenance efficiency of the embossed board, and greatly reduce the labor intensity of the staff.

Owner:广东正通博雅装饰工程有限公司

Service data cleaning method, device and electronic equipment

PendingCN112256688AAvoid data cleaning configurationImprove maintenance efficiencyMetadata text retrievalDatabase management systemsService systemData cleansing

The invention discloses a service data cleaning method, a device, electronic equipment and a machine readable storage medium. The method comprises the steps of obtaining service data to be subjected to data cleaning from a butted service system; determining a data element associated with the service data; and obtaining a conversion type named entity, a verification type named entity and an interpretation type named entity associated with the data element, and performing data cleaning on the service data based on the obtained conversion type named entity, verification type named entity and interpretation type named entity. According to the method, ordered data cleaning is carried out in sequence based on the plurality of named entities which are what you see is what you get, so that tediousdata cleaning configuration of a user is avoided, the data cleaning maintenance efficiency is improved, and accumulation and sharing utilization of the named entities are facilitated.

Owner:HANGZHOU DT DREAM TECH

Automatic drill rod cleaning device

InactiveCN107983689AImprove cleaning efficiencyEasy to cleanLiquid surface applicatorsDrying solid materials without heatHigh pressure waterHigh pressure

The invention relates to an automatic drill rod cleaning device, and belongs to the technical field of automatic cleaning devices for drilling tools. The device is disassembled through a fixing pieceand is arranged on a drill rod support, the fixing piece is fastened, a water inlet of a high pressure water pipeline is connected with a high pressure water pump, a high pressure water injector headinside a high pressure water jet part ejects high pressure water to clean a drill rod, the drill rod cleaned through the high pressure water jet part is wiped and dried through a rolling brush insidea rolling brush drying part, and after drying, a hairbrush inside an anti-rust oil applying part uniformly applies anti-rust oil in an anti-rust oil pipeline onto the drill rod.

Owner:常州琨瑶纺织品有限公司

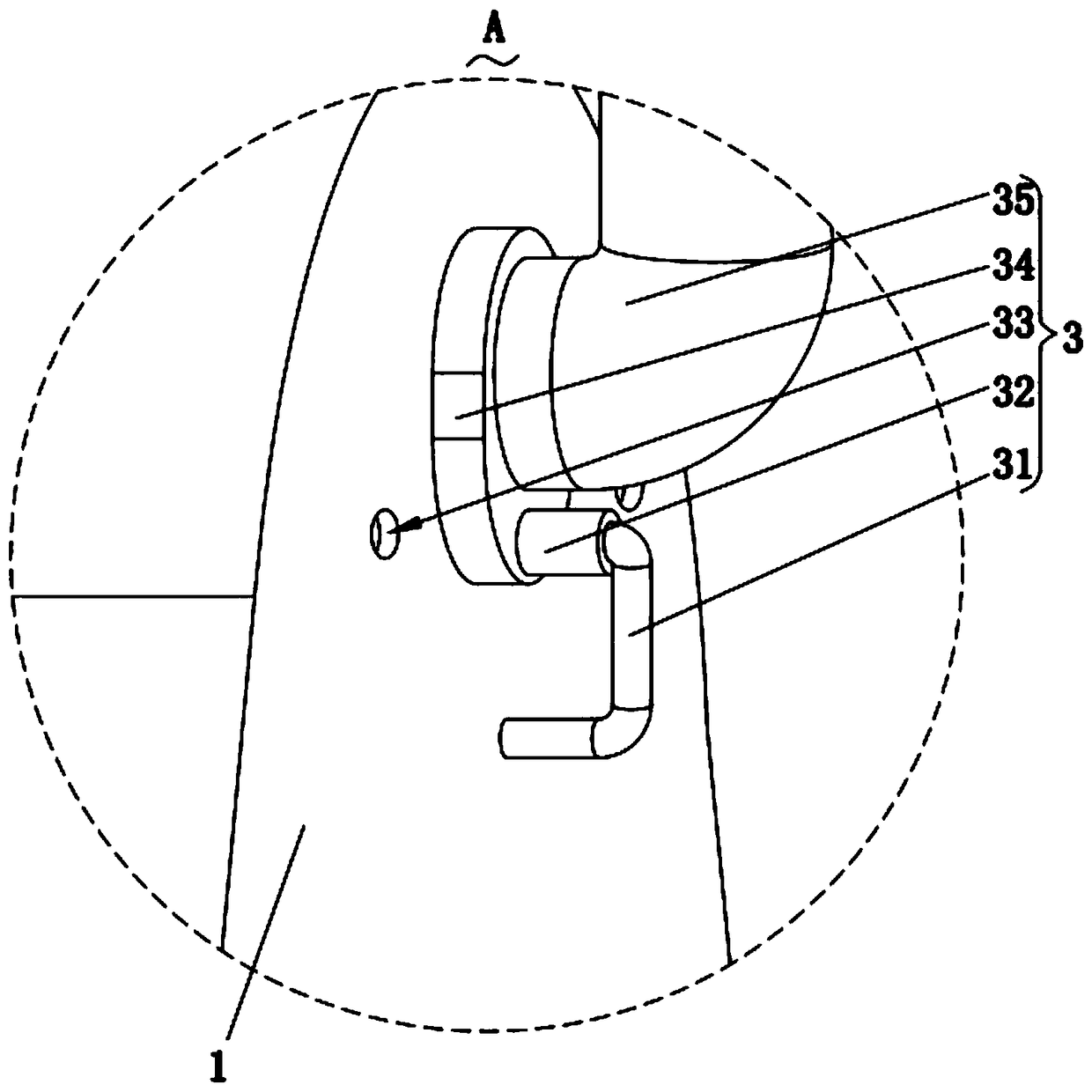

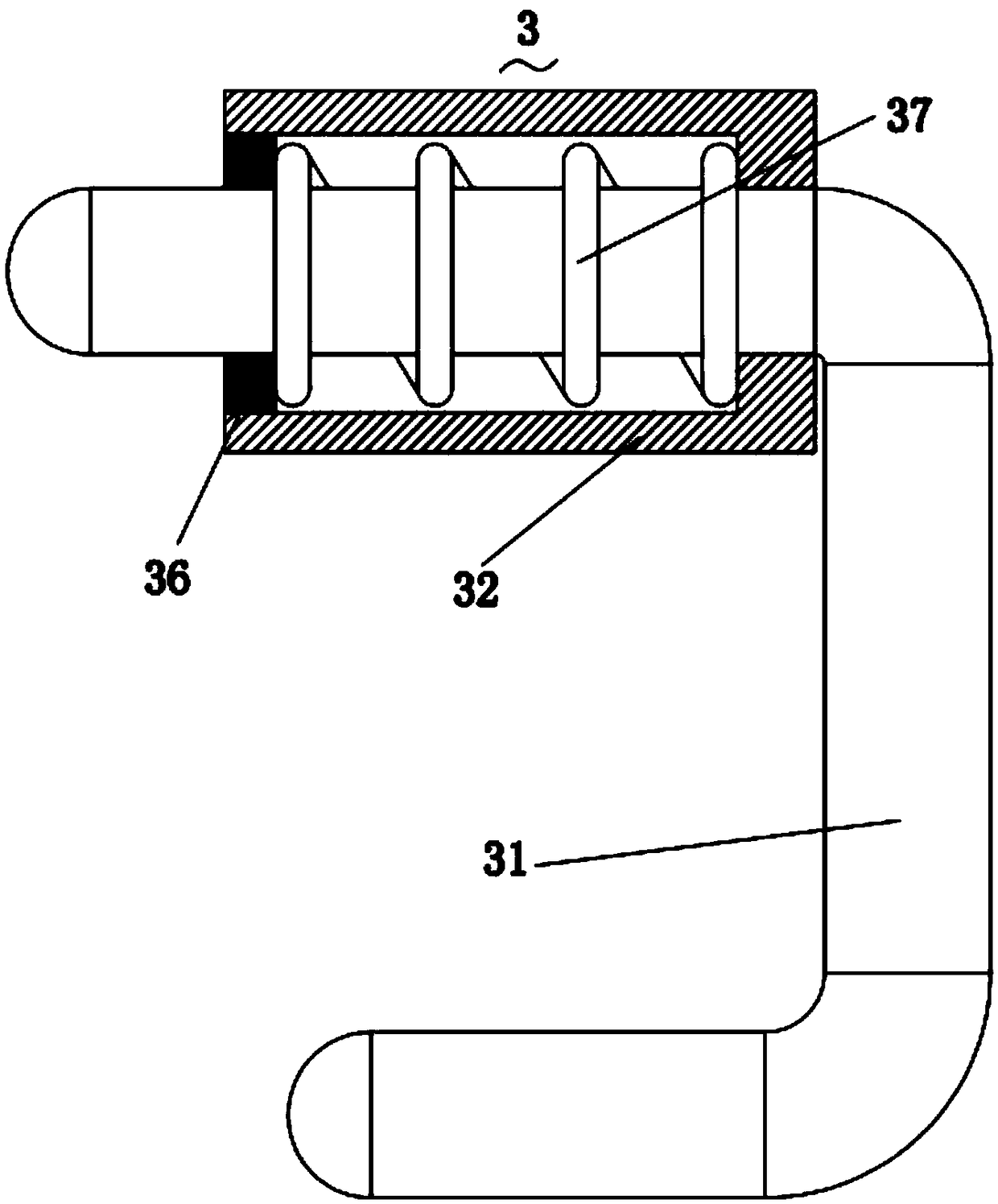

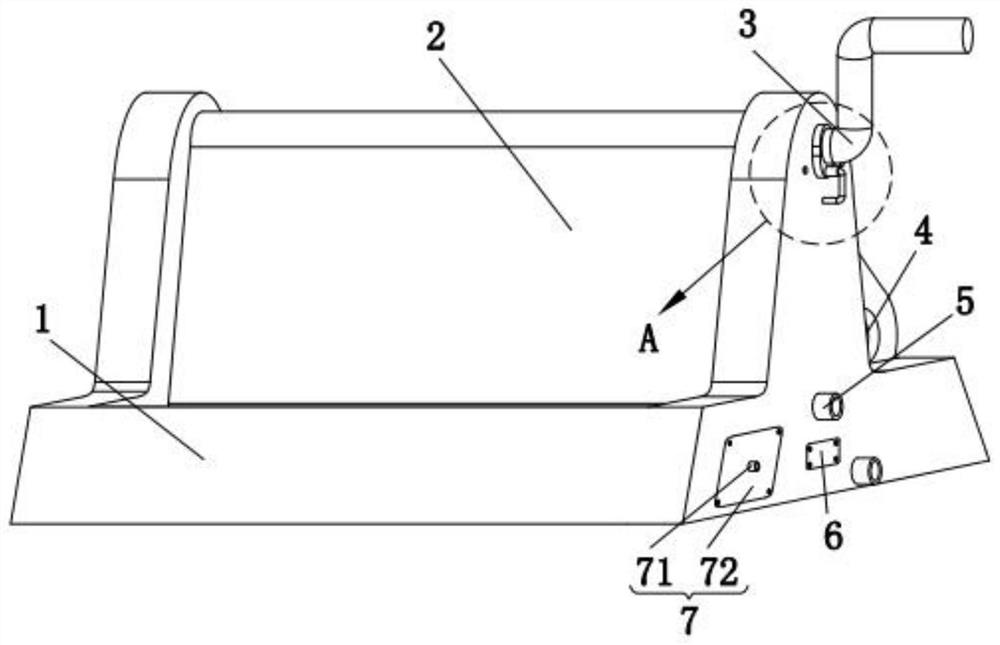

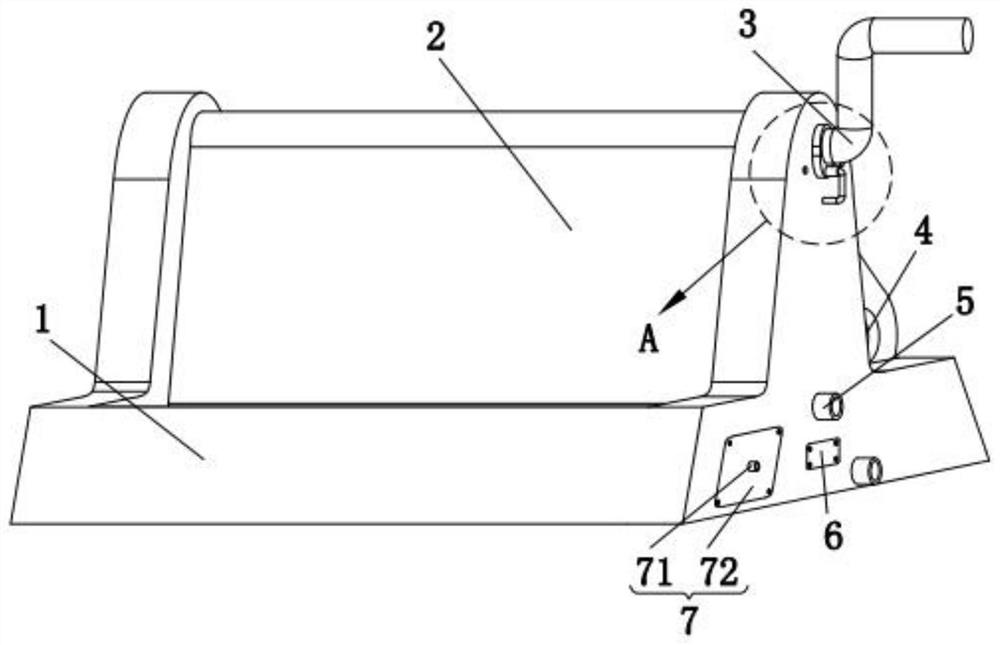

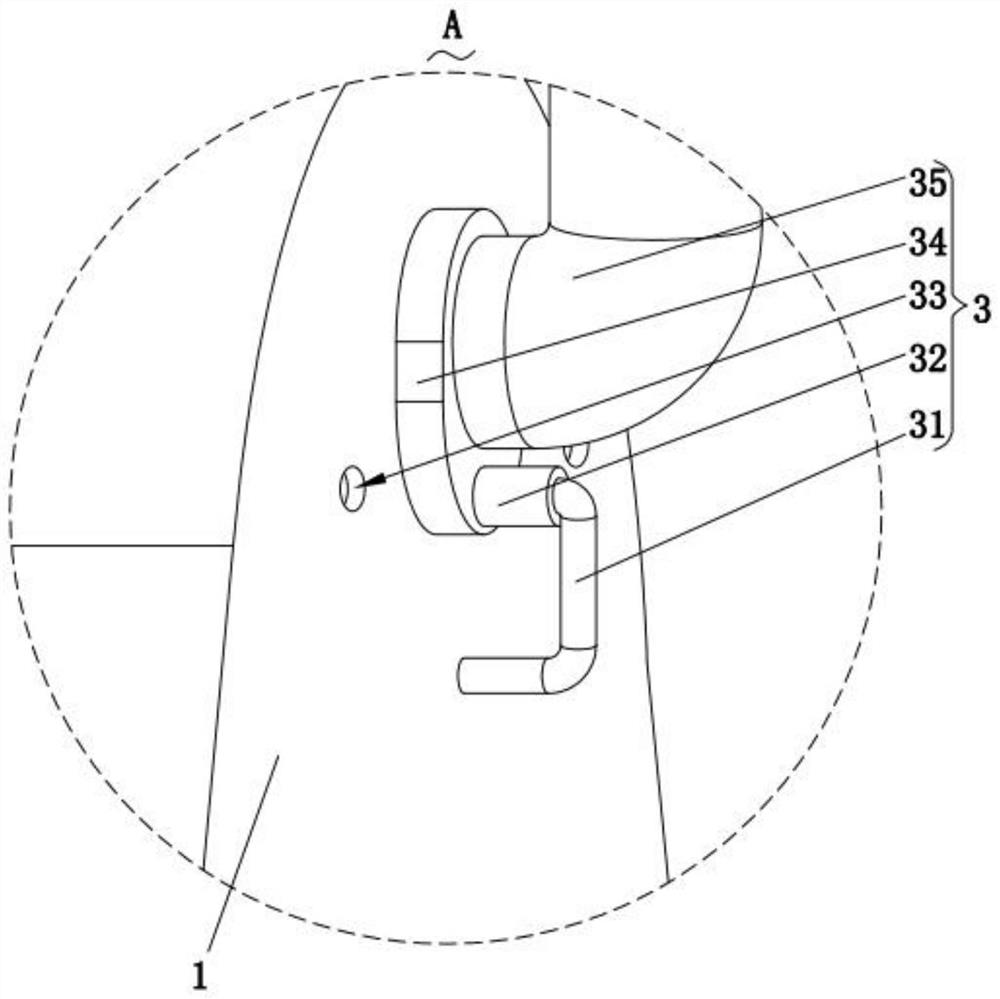

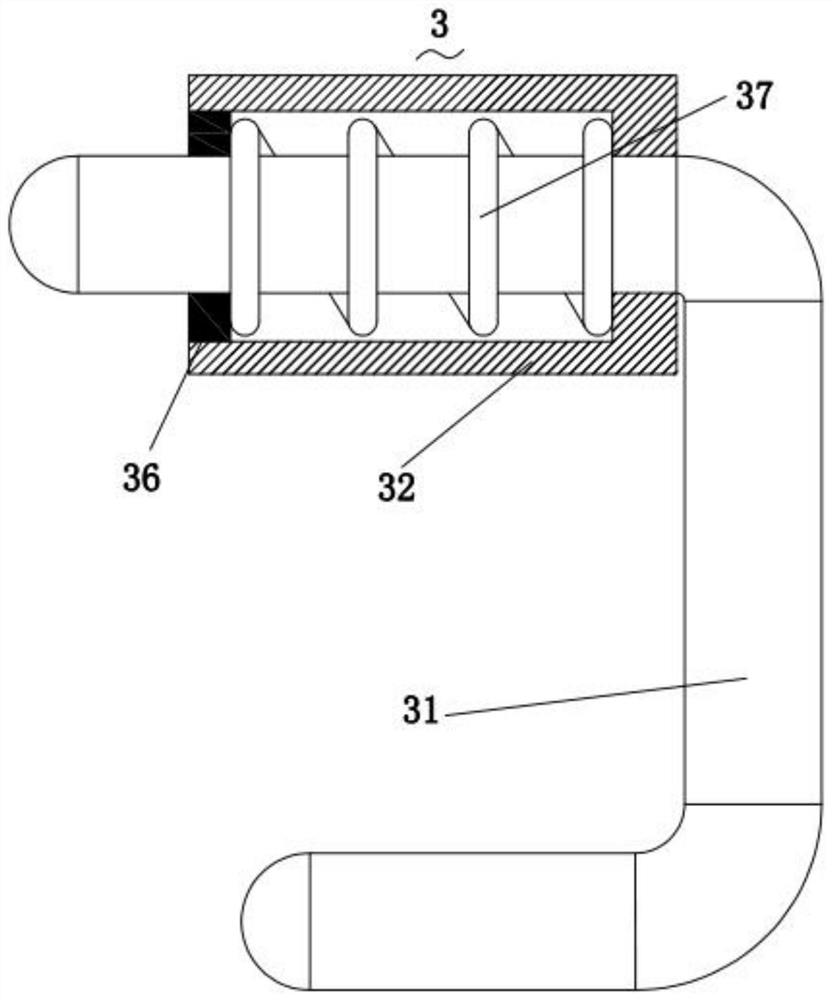

Oil pipeline oil cleaning device

ActiveCN109550751BImprove operational flexibilityEasy to fixHollow article cleaningThermodynamicsPetroleum oil

The invention relates to the field of pipeline cleaning equipment, in particular to an oil pipeline greasy dirt cleaning device, which comprises clamping structures, a guiding structure, a rocker, driving structures, a transmission structure, a cleaning structure and a storage frame. The side wall of a support frame of the rectangular structure for storing a cleaning waste liquid is provided withthe guiding structure for adjusting the distance between the two adjacent driving structures; the driving structures are provided with the clamping structures for clamping oil pipelines of different diameters; the end of the storage frame is fixedly provided with the transmission structure; and the transmission structure is provided with the cleaning structure for cleaning the oil pipeline. The two clamping structures of the invention are used together to facilitate the fixing of oil pipelines with different diameters, and the driving structures and the guiding structure are matched to be fixed to the side walls of the storage frame, so as to quickly fix oil pipelines of different lengths; and at the same time, the distance between the side wall of the cleaning structure and the center ofrotation of the transmission structure can be adjusted, which greatly improves the quality of cleaning and maintenance.

Owner:刘韬 +1

A method and device for processing card number data

ActiveCN105930331BImprove cleaning and maintenance efficiencyReduce maintenance costsDatabase updatingPayment architectureComputer hardwareExpiration Time

The invention discloses a method and device for processing card number data. According to the expiration time corresponding to the card number, the table group corresponding to the card number is determined, and the card number information corresponding to the card number is placed in at least one card number storage table of the table group; The table group is composed of multiple card number storage tables, each table group corresponds to an expiration time, and the expiration time corresponding to all card numbers in the table group is the same as the expiration time corresponding to the table group, and the card number information includes the card number and the card number Associated data; after the expiration time corresponding to a table group is reached, all the card number information in the table group is cleaned up. The card number data processing method and device provided in the embodiments of the present invention can improve the cleaning and maintenance efficiency of the card number data processing method and reduce maintenance costs.

Owner:CHINA UNIONPAY

Cleaning method of lithium battery coating die

ActiveCN113058810BGuaranteed accuracyImprove cleaning and maintenance efficiencyLiquid surface applicatorsSpraying apparatusMechanical engineeringLithium battery

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com