Antifouling self-cleaning column type composite insulator

A composite insulator and self-cleaning technology, which is applied in the field of post insulators, can solve the problems of reducing the service life of insulators, easily accumulating dirt on insulators, and time-consuming and laborious cleaning effects, so as to improve the service life of equipment, improve anti-pollution self-cleaning ability, The effect of saving post-maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

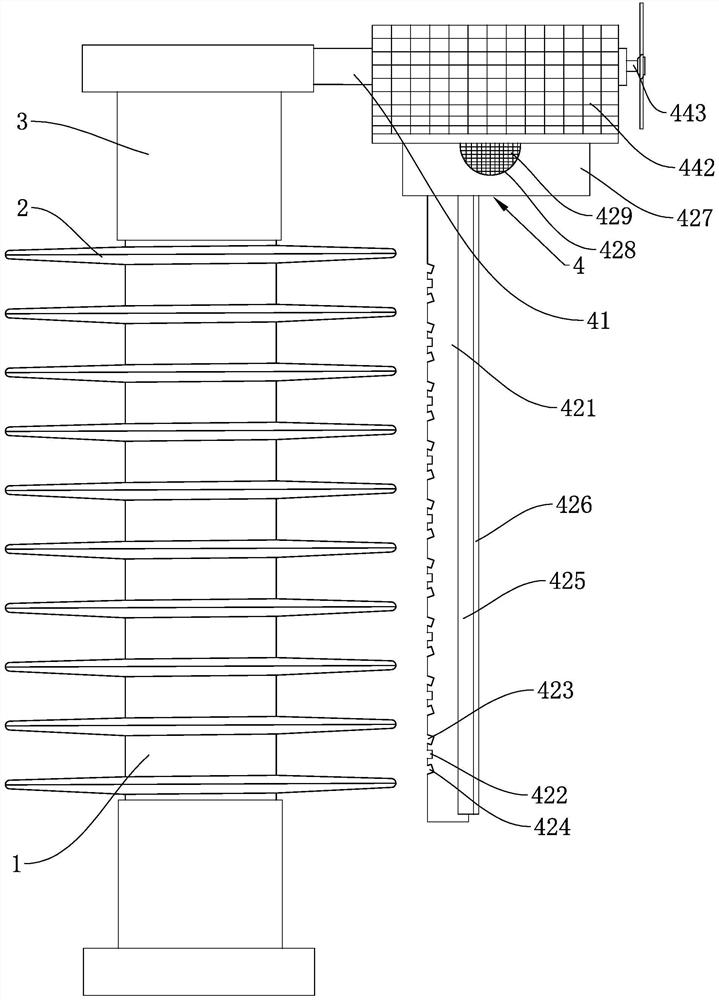

[0035] The following is attached Figure 1-2 The application is described in further detail.

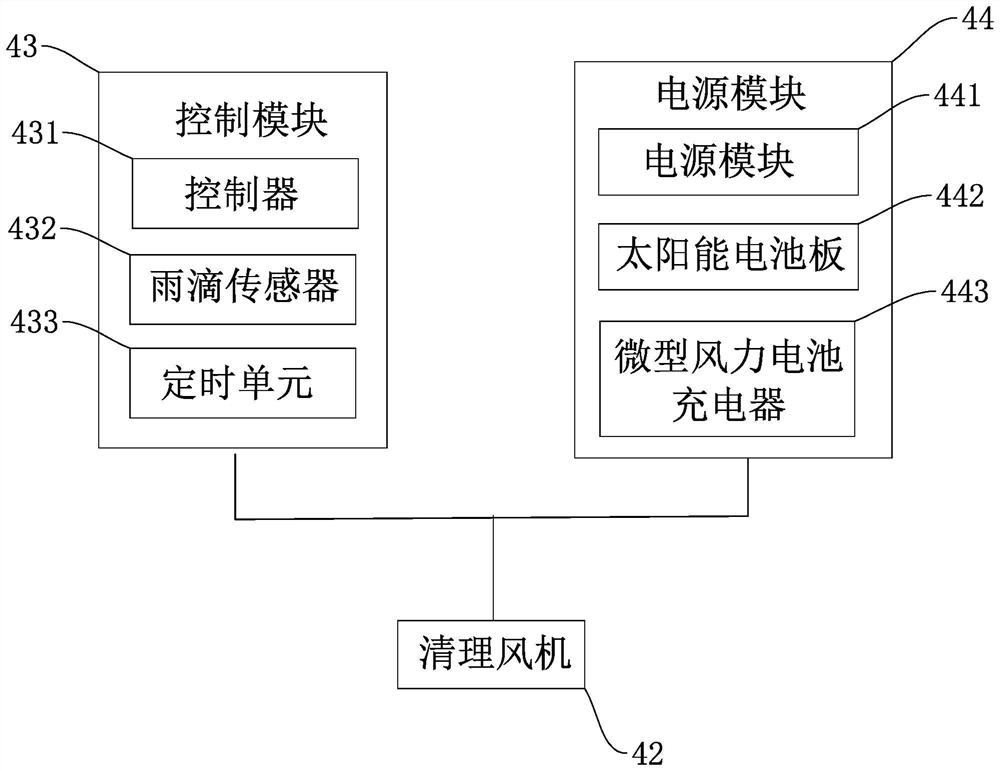

[0036] The embodiment of the present application discloses an anti-pollution self-cleaning post type composite insulator. refer to figure 1 and figure 2 , an anti-fouling self-cleaning post type composite insulator, comprising an insulating core 1, a plurality of sheds 2 sleeved on the insulating core 1 and connecting fittings 3 installed at both ends of the insulating core 1. The fittings on the top of the insulating core 1 are connected with a cleaning mechanism 4 for cleaning the shed 2 . The cleaning mechanism 4 includes a base 41 , a cleaning blower 42 installed on the base 41 , a control module 43 for controlling the start of the cleaning blower 42 and a power supply module 44 for powering the cleaning blower 42 and the control module 43 . The air outlet of the cleaning fan 42 is connected with a cleaning air duct 421. The cleaning air duct 421 is arranged along the length...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com