Dosing and stirring system

A technology of stirring system and stirring shaft, which is applied in the direction of mixer accessories, mixers with rotating stirring devices, dissolving, etc., can solve the problems of limited space at the feeding port, poor effect, liquid leakage, etc., and achieve simple structure, convenient use, and improved efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

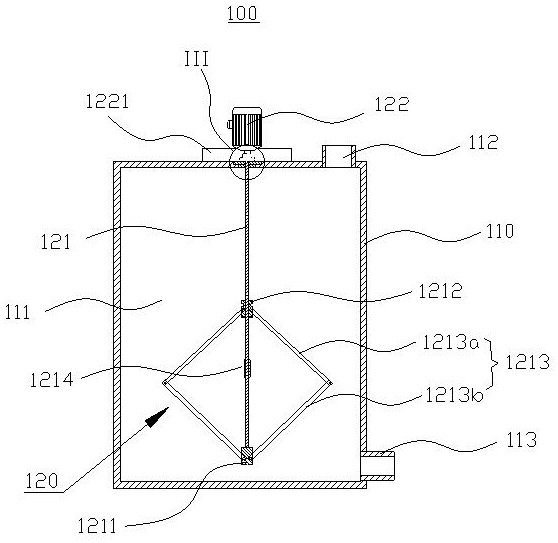

[0028] This embodiment provides a dosing and stirring system 100, refer to figure 1 As shown, it includes a tank body 110 and a stirring device 120 , a stirring chamber 111 is formed inside the tank body 110 , a feeding port 112 is provided at the top of the stirring chamber 111 , and a discharge port 113 is provided at the bottom.

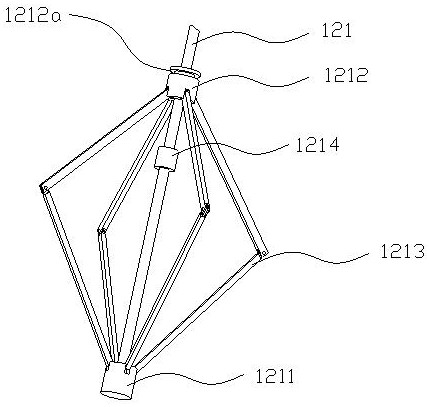

[0029] Among them, such as figure 1 and figure 2As shown, the stirring device 120 includes a stirring shaft 121 located in the stirring chamber 111 and a motor 122 for driving the stirring shaft 121 to rotate along its axis. The top end of the stirring shaft 121 passes through the tank body 110 and is connected to the motor 122 . The stirring shaft 121 is provided with a fixed part 1211, a sliding part 1212 and a stirring blade 1213, the fixed part 1211 is located at the bottom of the stirring shaft 121, and the sliding part 1212 is slidably sleeved on the stirring shaft 121, and can slide along the length direction of the stirring shaft 121 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com