Automatic drill rod cleaning device

An automatic cleaning and drill pipe technology, which is applied to the device, cleaning method and utensils for coating the surface with liquid, cleaning method using liquid, etc. , large energy consumption and other problems, to achieve the effect of convenient automatic cleaning, improve operation efficiency, and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

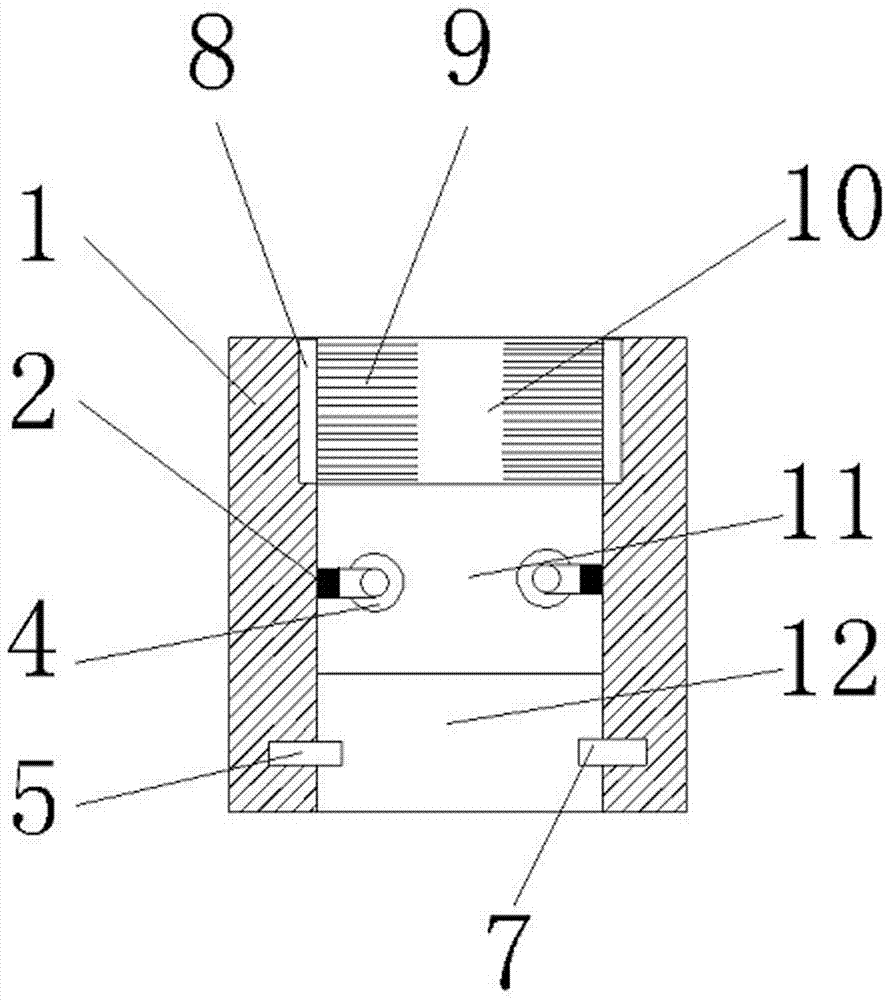

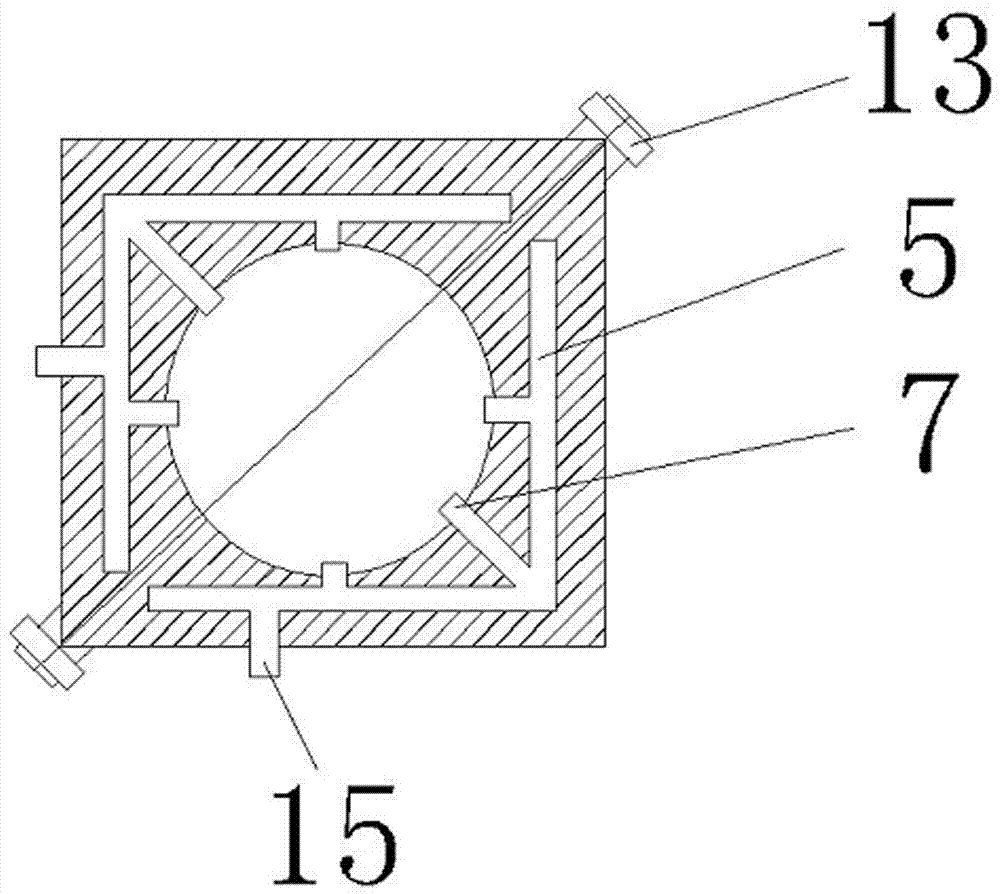

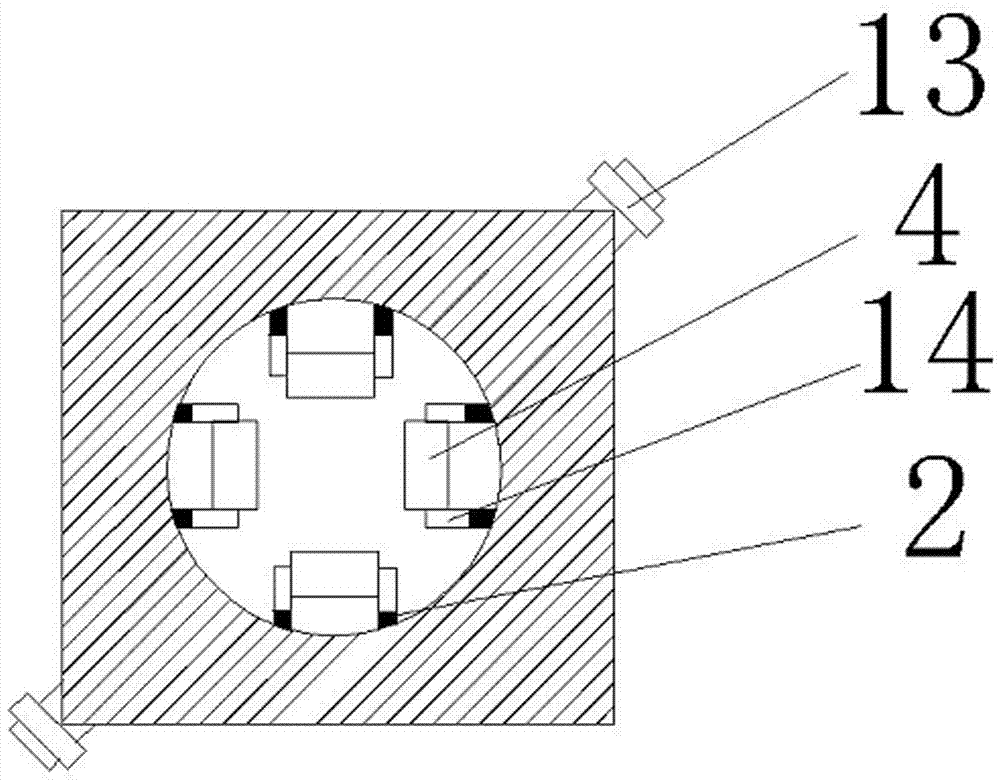

[0019] An automatic cleaning device for drill pipes, including a casing 1, the casing 1 is divided into three parts, a high-pressure water jet cleaning part 12, a rolling brush drying part 11, an anti-rust oil coating part 10, and a high-pressure water jet part 12 includes a high-pressure water pipeline 5, a water inlet 15 of a high-pressure water pipeline, a high-pressure water spray head 7 and a fixing member 13. The roller drying part mainly includes a roller brush 4, which is connected to the housing 1 through a bracket 14, and the end of the bracket 14 is provided There is an elastic device 2 , and the antirust oil application part 10 mainly includes an antirust oil pipeline 8 and a brush 9 . An application method of an automatic drill pipe cleaning device is as follows: disassemble the device through the fixing part 13, install it on the drill pipe support, fasten the fixing part 13, connect the water inlet 15 of the high-pressure water pipe to the high-pressure water pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com