Paint spraying tray capable of being rapidly replaced and cleaned for aluminum alloy hub machining

An aluminum alloy wheel hub, fast technology, applied in the field of painting, can solve the problems of difficult disassembly, troublesome and time-consuming installation, nut bonding, etc., and achieves the effect of simple device structure, improved efficiency, and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

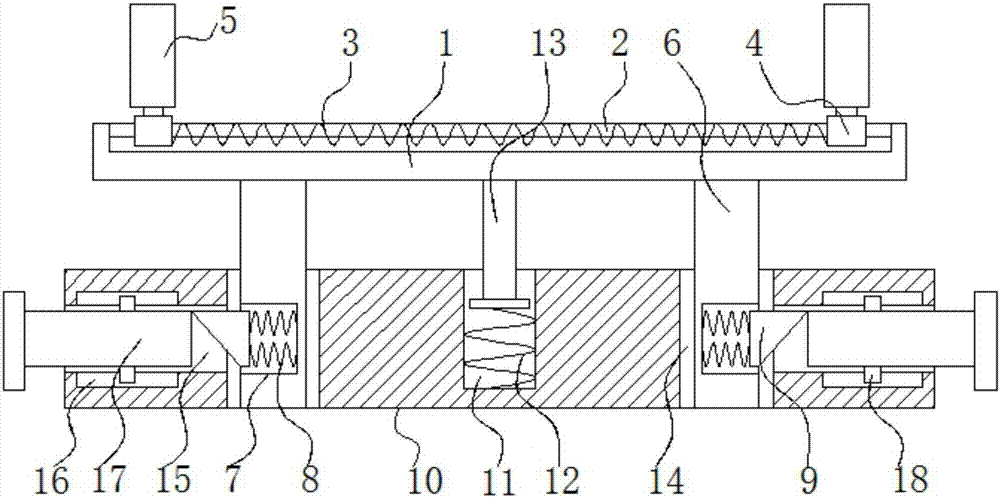

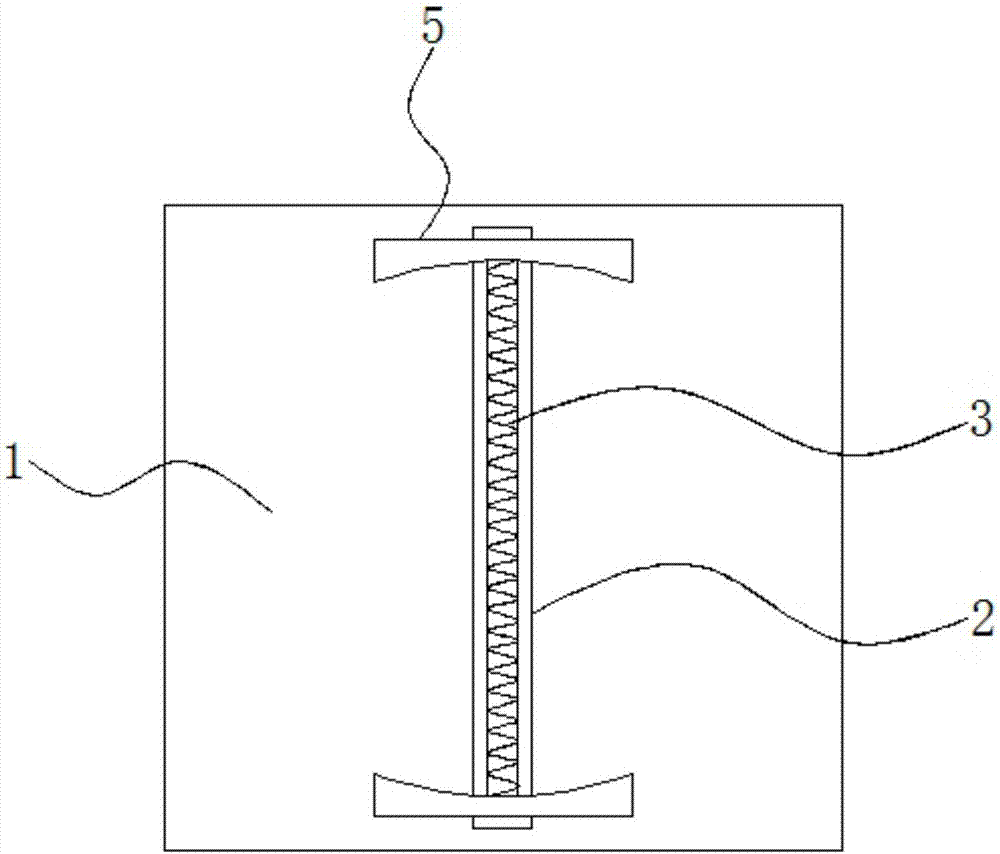

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

[0017] refer to Figure 1-3 , a paint spraying tray for processing aluminum alloy wheels that can be quickly replaced and cleaned, including a main body 1, two sets of fixing rods 6 are symmetrically welded on the bottom of the main body 1, and the fixing rods 6 and the main body 1 are perpendicular to each other, and the two sets of fixing rods 6 are far away from the main body 1 One end of each is provided with a first groove 7, and the opening directions of the two groups of first grooves 7 are far away from each other, and the insides of the two groups of first grooves 7 are connected with two groups of second springs 8, and the second springs 8 prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com