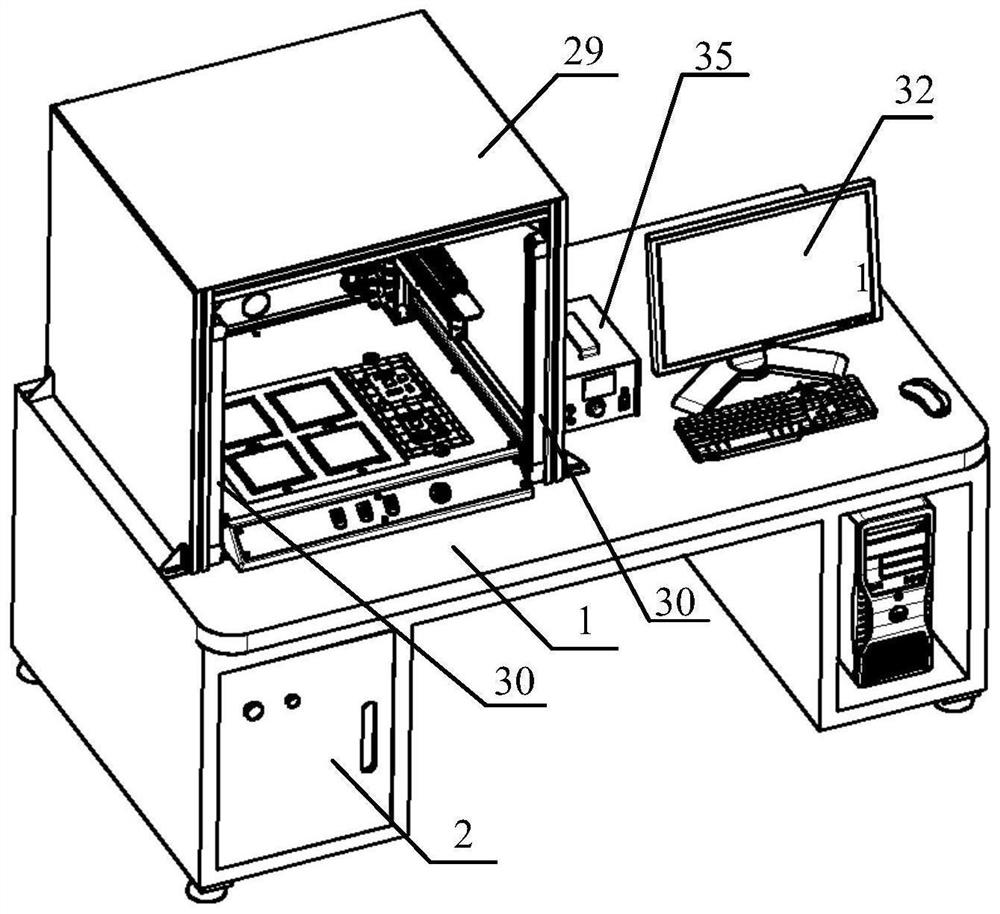

Automatic cutting and pasting equipment for heat conduction pad and using method

A thermal pad cutting technology, applied in the field of machinery, can solve problems such as heavy workload, low operating efficiency, affecting product delivery progress and product quality, and achieve low cost, improve production efficiency and quality, and improve thermal pad cutting and the effect of pasting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

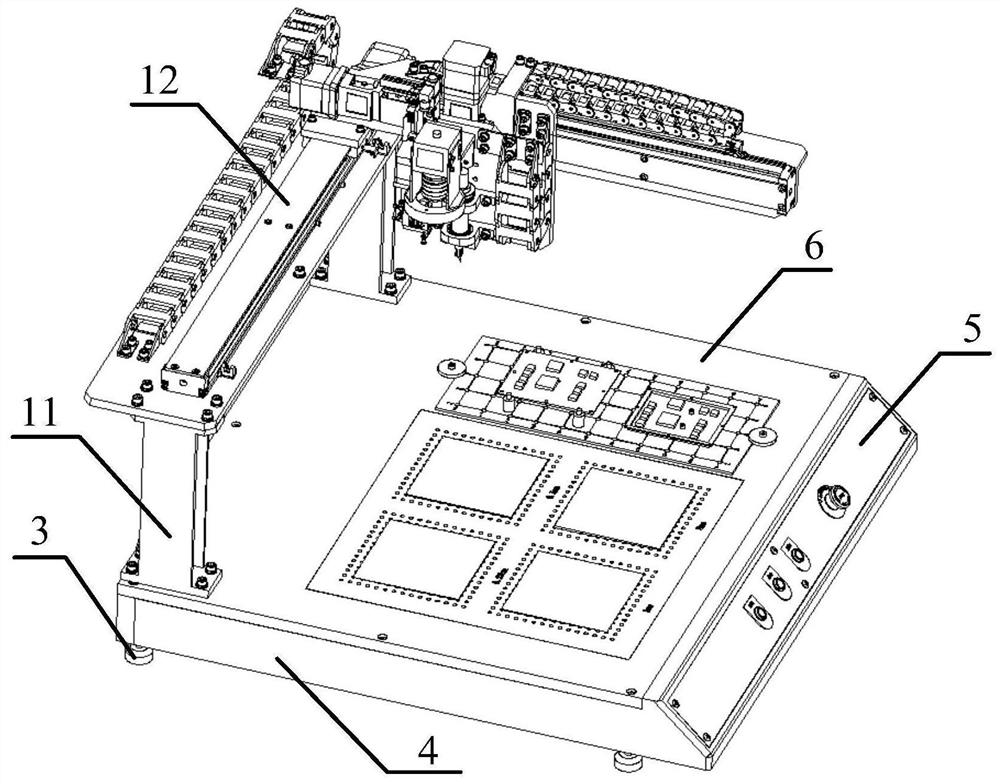

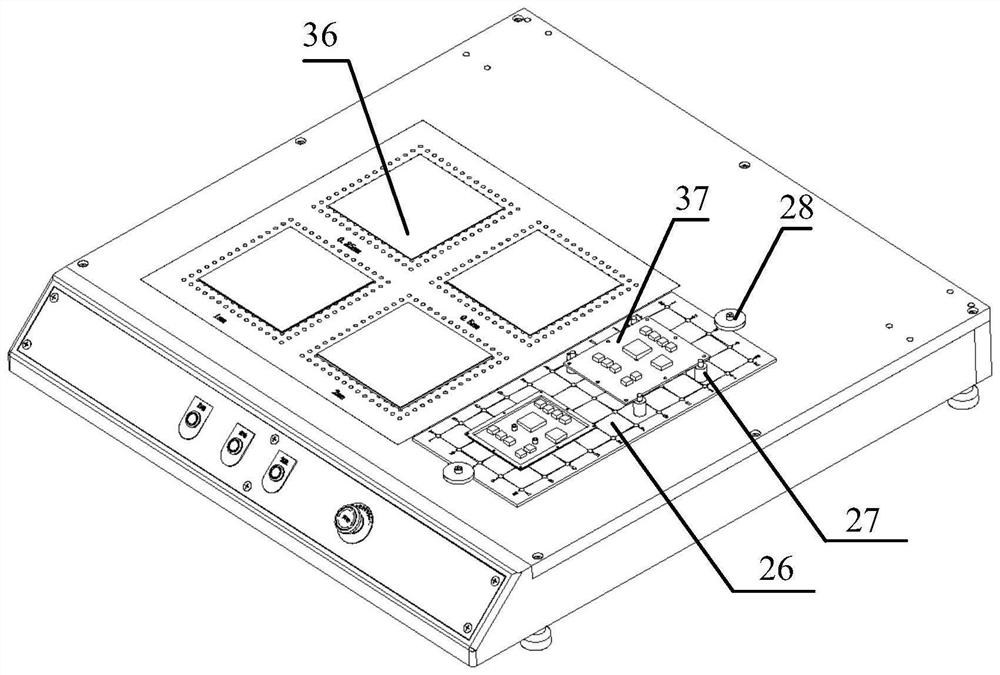

[0027] The automatic cutting and pasting equipment for heat conduction pads of the present invention includes the PVC cutting-resistant rubber pads for placing heat conduction pads and the measurement substrate for placing circuit boards or heat sinks, CCD cameras, XYZ modules, ultrasonic cutting devices and vacuum suction devices, wherein the CCD cameras mainly It is used to automatically identify the size, shape and position of the heat conduction pad and the position of the chip / heat dissipation boss that needs to be pasted with the heat conduction pad. The XYZ module drives the CCD camera to take pictures directly above the PCB board or heat sink on the measurement substrate, and automatically recognizes the need to paste the heat conduction pad. The size and position of the chip / boss of the pad, the XYZ module drives the ultrasonic cutter to cut the thermal pad with the corresponding size and thickness, the vacuum suction device absorbs the cut thermal pad, and moves to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com