Preparation process of ultra-black high-performance Ti-DLC coating

A preparation process, high-performance technology, applied in the field of sputtering coating, can solve the problems of poor thermal stability, poor thermal stability of the film, large internal stress, etc., to achieve the effect of excellent coating performance and extended application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

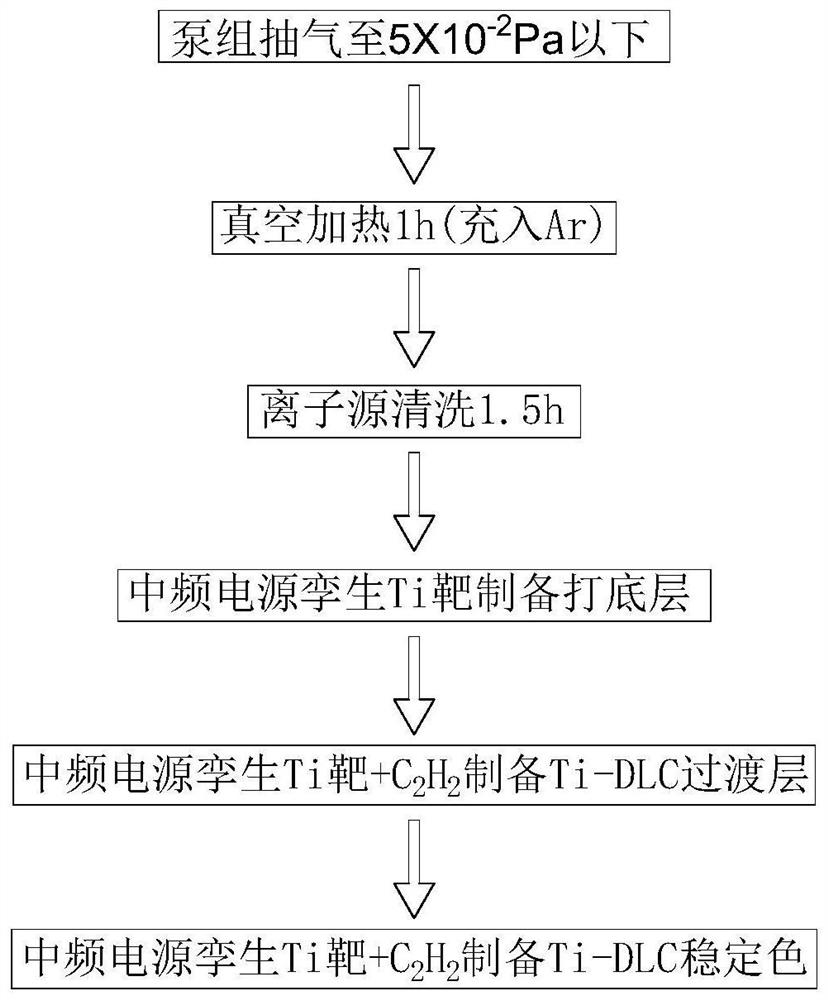

[0029] Such as figure 1 Shown:

[0030] 1) The pump set pumps air to the vacuum chamber

[0031] Clamp the workpiece after surface cleaning on the special fixture, turn on the rotary vane pump to pump the vacuum to 10Pa after the workpiece enters the vacuum chamber, and turn on the molecular pump to pump the air pressure to 1×10 -2 Pa.

[0032] 2) Vacuum heating for 1h

[0033] Fill the vacuum chamber with 0sccmAr, the air pressure is 1×10 -2 Pa, turn on the vacuum chamber heater and the magnetic filter power supply, set the heating temperature to 350°C for 0.5h.

[0034] Function: The chamber heater is mainly used to desorb gas molecules such as water vapor attached to the inner wall of the chamber, lining board, turret, and workpiece. The heat generated by the magnetic filter power supply can cool the inner wall of the magnetic filter elbow and the bellows bush Carry out baking degassing. The effects of filling the vacuum chamber with Ar mainly include: first, the des...

Embodiment 2

[0053] Such as figure 1 Shown:

[0054] 1) The pump set pumps air to the vacuum chamber

[0055] Clamp the workpiece after surface cleaning on the special fixture, turn on the rotary vane pump to pump the vacuum to 20Pa after the workpiece enters the vacuum chamber, and turn on the molecular pump to pump the air pressure to 9×10 -2 Pa.

[0056] 2) Vacuum heating for 1h

[0057] Fill the vacuum chamber with 500 sccmAr, the air pressure is 3×100Pa, turn on the vacuum chamber heater and the magnetic filter power supply, set the heating temperature to 260°C for 0.75h.

[0058] Function: The chamber heater is mainly used to desorb gas molecules such as water vapor attached to the inner wall of the chamber, lining board, turret, and workpiece. The heat generated by the magnetic filter power supply can cool the inner wall of the magnetic filter elbow and the bellows bush Carry out baking degassing. The effects of filling the vacuum chamber with Ar mainly include: first, the des...

Embodiment 3

[0077] Such as figure 1 Shown:

[0078] 1) The pump set pumps air to the vacuum chamber

[0079] Clamp the workpiece after surface cleaning on the special fixture, turn on the rotary vane pump to pump the vacuum to 28Pa after the workpiece enters the vacuum chamber, and turn on the molecular pump to pump the air pressure to 5×10 -2 Pa.

[0080] 2) Vacuum heating for 1h

[0081] Fill the vacuum chamber with 250 sccmAr, the air pressure is 1.5×100Pa, turn on the vacuum chamber heater and magnetic filter power supply, set the heating temperature to 200°C for 1.5h.

[0082] Function: The chamber heater is mainly used to desorb gas molecules such as water vapor attached to the inner wall of the chamber, lining board, turret, and workpiece. The heat generated by the magnetic filter power supply can cool the inner wall of the magnetic filter elbow and the bellows bush Carry out baking degassing. The effects of filling the vacuum chamber with Ar mainly include: first, the desorb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap