Coated device with black multilayer film and preparation method thereof

A multi-layer film and black technology, which is applied in the direction of plating, coating, sputtering plating, etc. of superimposed layers, can solve the problems of large environmental pollution, low L value, poor corrosion resistance and wear resistance, etc. Strong corrosion resistance, good metallic luster, and strong wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

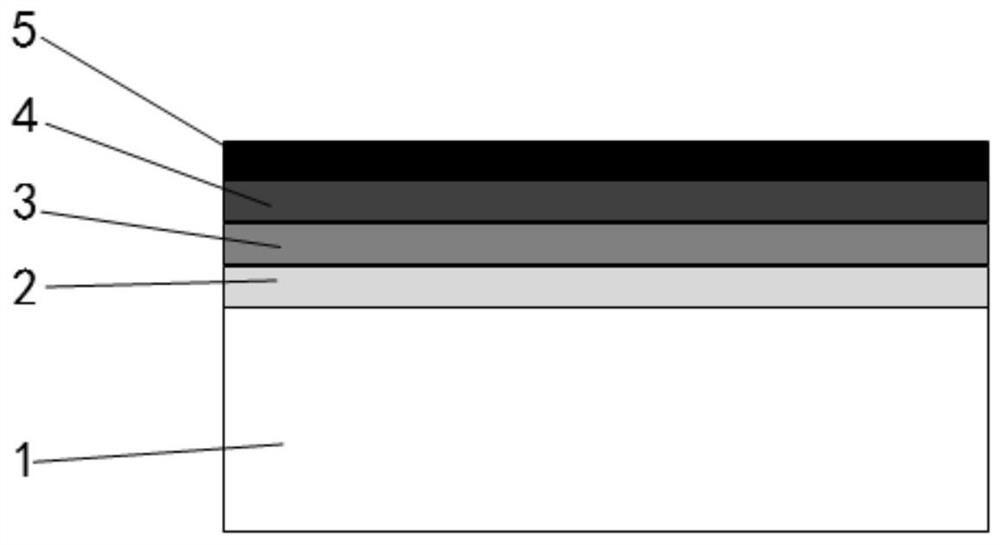

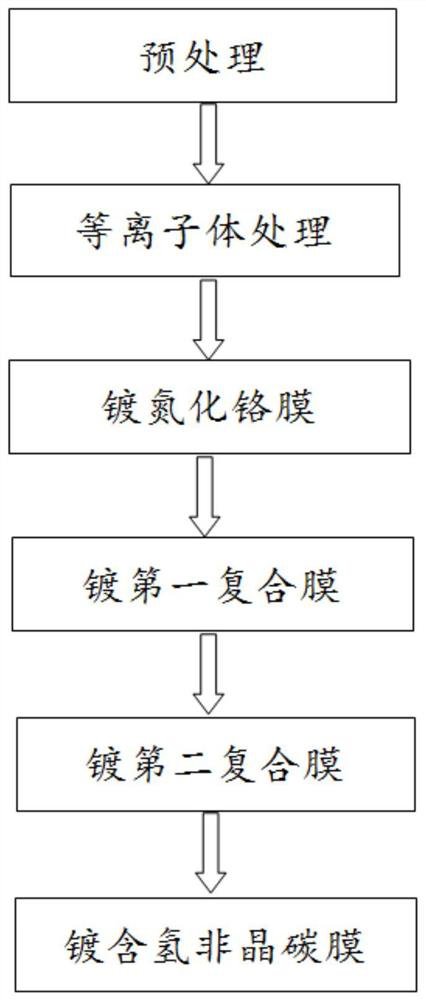

[0038] The preparation method of the coating device with black multilayer film provided by the invention, main steps are as follows:

[0039] 1) performing plasma etching on the substrate of the black multilayer film to be plated;

[0040] 2) plating a chromium nitride film on the surface of the substrate treated in step 1); preferably the thickness of the chromium nitride film is 50-90nm;

[0041] 3) the first composite film is plated on the surface of the chromium nitride film formed in step 2), and the first composite film is a mixed coating layer of chromium carbonitride, chromium carbide, chromium nitride and doped hydrogen-containing amorphous carbon , the doping elements in the doped hydrogen-containing amorphous carbon include nitrogen and chromium; preferably, the thickness of the first composite film is 40-80nm;

[0042] 4) plate a second composite film on the surface of the first composite film formed in step 3), and the second composite film is a mixed coating of ...

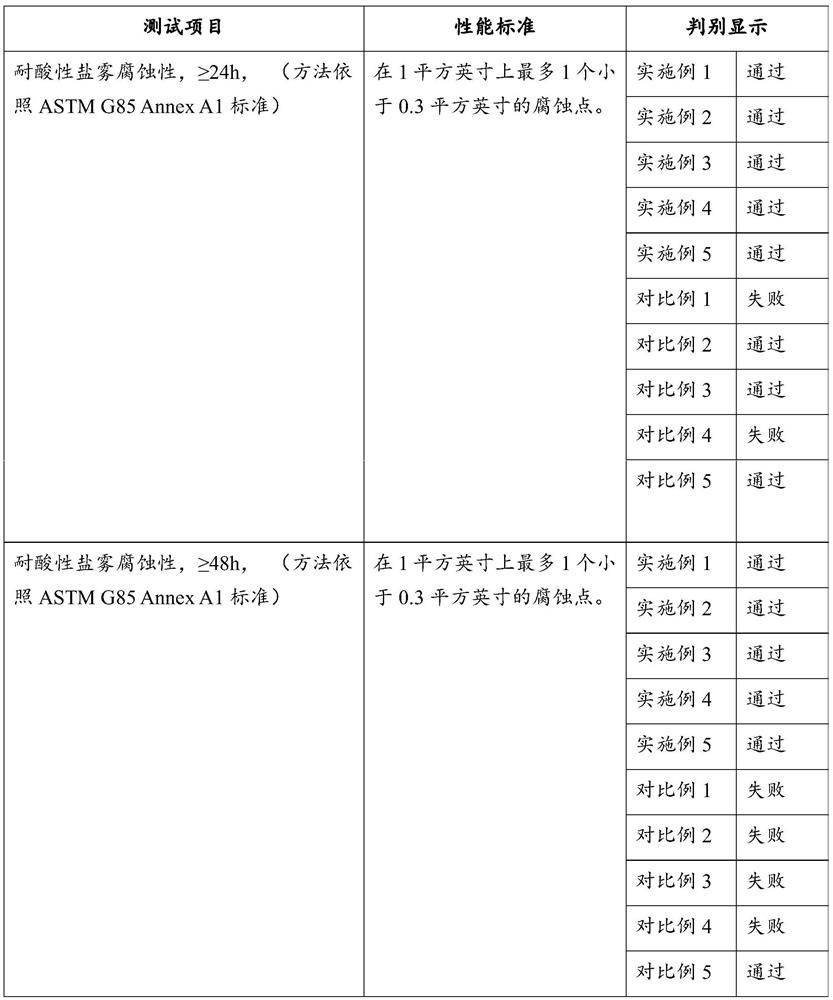

Embodiment 1

[0069] The method for plating a black multilayer film on the surface of a sanitary product body (that is, a substrate) of a metal material (copper alloy in this example) electroplated with chromium, and the specific steps include:

[0070] Pretreatment: Clean the surface of the chrome-plated bathroom product body to remove oil, wax and dust. Then proceed as follows.

[0071] Step 1): Transfer the pretreated bathroom product body to the hanger of the vacuum coating machine, and the vacuum degree reaches 3.5×10 -5 During Torr, the surface of the bathroom product body is treated with plasma. The specific process conditions are as follows: 100 sccm argon gas is introduced, the ion source power is 350 W, the furnace temperature is 150° C., and the processing time is 10 min.

[0072] Step 2): The workpiece processed in step 1) is plated with chromium nitride film by multi-arc ion coating technology, and the process parameters are as follows: multi-arc current 50A, negative bias vo...

Embodiment 2

[0077] The method for plating a black multilayer film on the surface of a sanitary product body of electrochrome-plated metal material (in this example, zinc alloy), the specific steps include:

[0078] Pretreatment: Clean the surface of the chrome-plated bathroom product body to remove oil, wax and dust. Then proceed as follows.

[0079] Step 1): Transfer the pretreated bathroom product body to the hanger of the vacuum coating machine, and the vacuum degree reaches 3.5×10 -5 During Torr, the surface of the bathroom product body is treated with plasma. The specific process conditions are as follows: 100 sccm argon gas is introduced, the ion source power is 350 W, the furnace temperature is 145° C., and the processing time is 10 min.

[0080] Step 2): The workpiece processed in step 1) is plated with chromium nitride film by multi-arc ion coating technology, and the process parameters are as follows: multi-arc current 50A, negative bias voltage 240V, duty cycle 75%, argon gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap