An automatic deformation monitoring equipment for subway foundation pit

A technology for deformation monitoring and foundation pits, which is applied in the directions of measuring instruments, measuring devices, surveying and navigation, etc., to achieve the effect of increasing the range and improving the adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

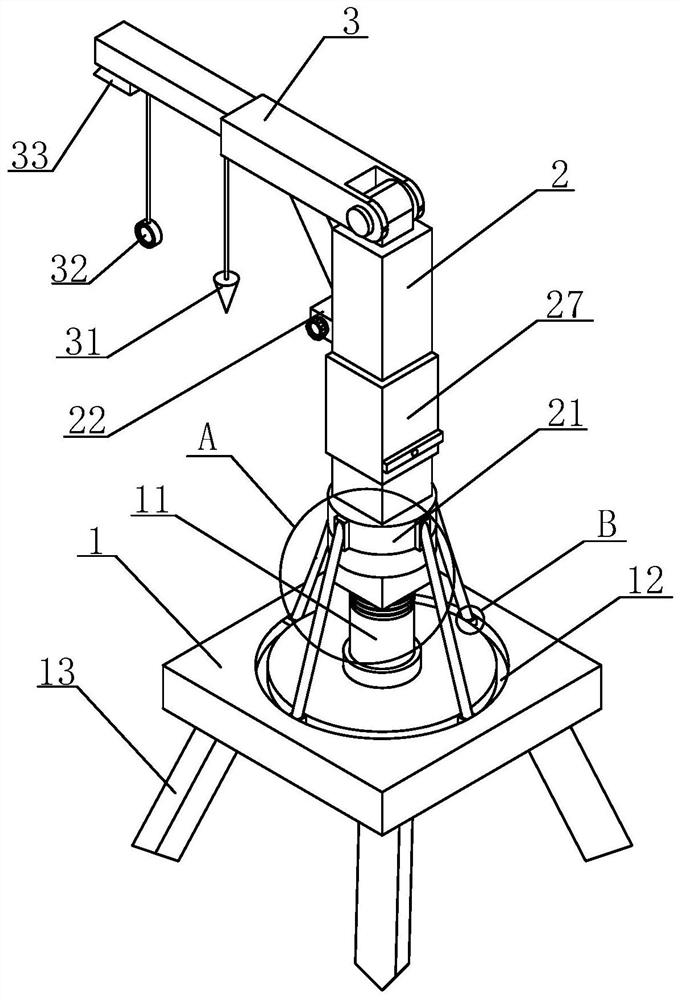

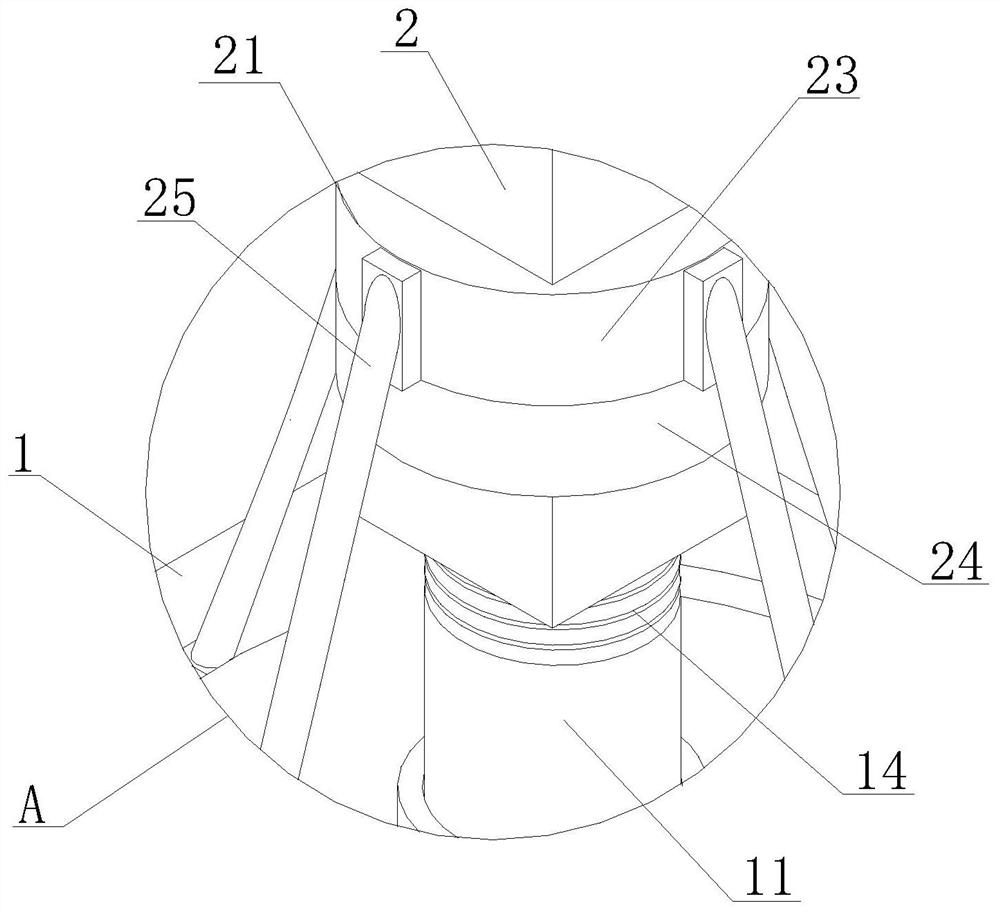

[0024] Example 1, in the present embodiment, the base 1 includes a connecting column 11, the outer wall of the connecting column 11 is provided with a slow pressure thread 14, the connection column 11 is connected by a bottom inner wall thread of the column 2 is provided with a slow pressure thread 14, the surface of the base 1 and away from the circumference of the connecting column 11 is opened with a buffer groove 12, the bottom four corners of the base 1 are fixed to connect the support legs 13, wherein the cushion groove 12 is provided to facilitate the rotation of the block 26 in the buffer groove 12 rotation, Convenient column 2 supports when turning to adjust the height.

Embodiment 2

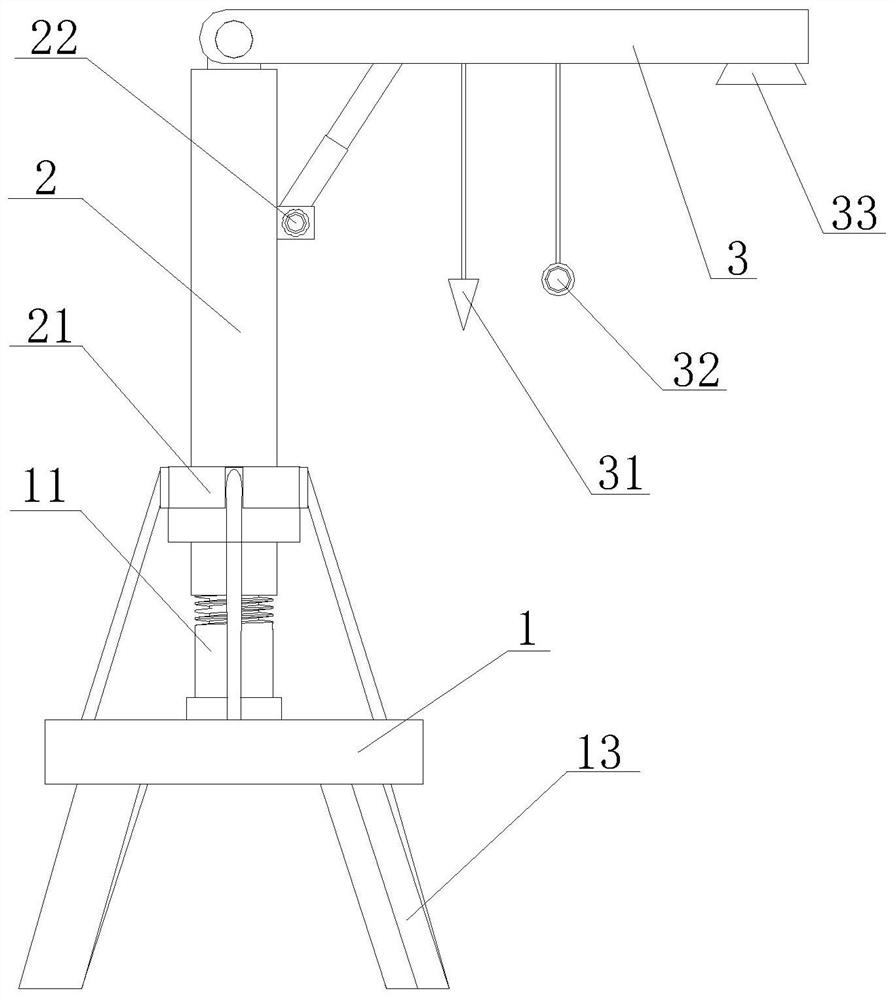

[0025] Example 2, the outer wall of the column 2 and near the bottom is provided with a support base 21, the outer wall of the column 2 and near the top is provided with a hydraulic mechanism 22, preferably, the hydraulic mechanism 22 is set to adjust the angle of the telescopic monitoring rod 3, so that the prism is located in the field of view of the total station, the height of the prism is determined by the total station, and then the height difference is detected by other detection points, the support base 21 includes a pressure rotating seat 23 and a pressure extrusion seat 24, The bottom inner wall of the pressure extrusion seat 24 is connected to the inner wall rotation of the rotating seat 23, preferably, the rotating block 23 is set to facilitate the rotation of the guard rod 25, the outer wall of the rotating seat 23 is evenly provided with a guard rod 25, the bottom of the guard rod 25 is fixedly connected with the slider 26, the outer wall of the slider 26 is connecte...

Embodiment 3

[0026] Example 3, in the present embodiment, the top center of the column 2 is provided with a rotating block, the outer wall of the rotating block is provided with a through hole, the telescopic monitoring rod 3 near the end of the column 2 is opened with a rotating groove, the inner wall of the rotating groove is opened with a through hole that is compatible with the rotating block, and the two adaptable through holes the inner wall is inserted with a fixed pin, the telescopic monitoring rod 3 is fixed by the fixed pin set with the column 2 fixed connection, the top of the hydraulic mechanism 22 is provided with a hydraulic rod, The top of the hydraulic rod is fixedly connected to the bottom of the telescopic monitoring rod 3 and away from the side of the lead hammer 31.

[0027] The following is a specific introduction to the working principle of the automatic deformation monitoring equipment for the subway foundation pit.

[0028] as Figure 1-4 As shown, when used, first set the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com