A kind of reactive ion etching device and method for continuously preparing large-area nano textured surface

A technology of reactive ion etching and nano suede, which is applied in the direction of nanotechnology, sustainable manufacturing/processing, transportation and packaging, etc., can solve the problems of low production capacity and large surface damage, so as to improve production capacity, ensure rapid continuity, The effect of continuous dynamic etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] 1. Clean and pretreat the pre-fabricated silicon wafer to obtain the damaged silicon wafer.

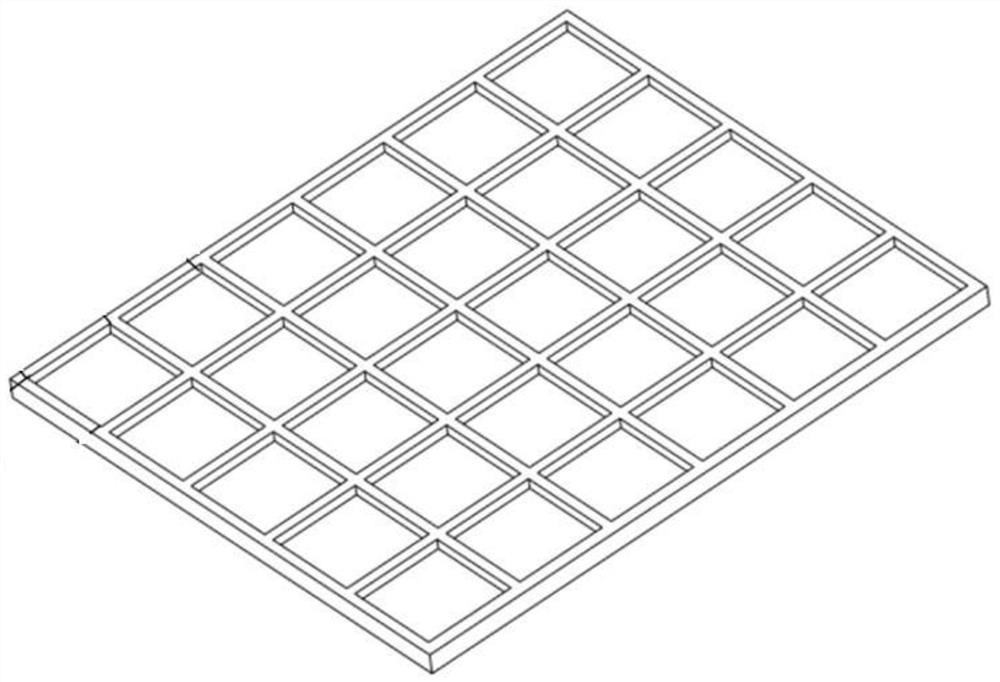

[0062] 2. Put the damaged silicon wafer on the carrier plate of the loading table, and the carrier plate is driven by the transmission rollers into the process chamber through the loading chamber and the process buffer chamber in turn;

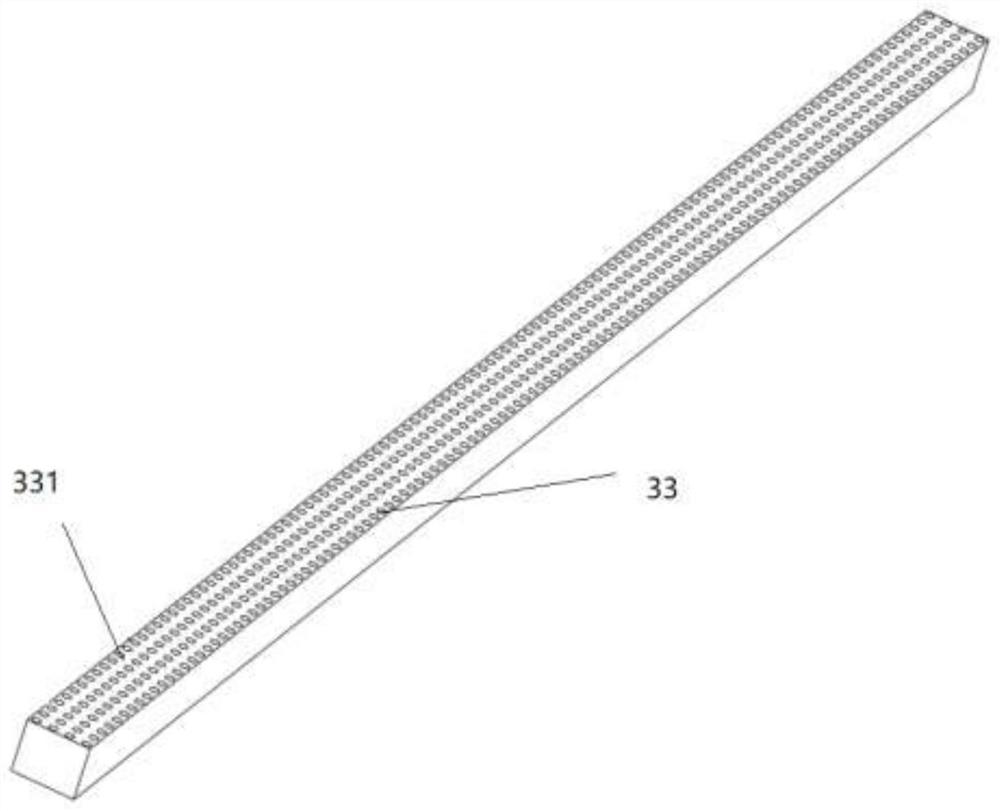

[0063] 3. Turn on the vacuuming equipment, press the air pressure until the predetermined vacuum value is 1Pa, and feed SF from the process air intake equipment 6 , O 2 and SiCl 4 Etching gas, the gas flow rate is 1900sccm, 3000sccm and 1500sccm respectively, turn on the magnetic field device, the etching gas enters the process chamber uniformly from the linear ion source distribution holes, and maintain the process chamber pressure at 24Pa.

[0064] 4. Turn on the radio frequency power supply, turn on the magnetic field device, the power of the high frequency power supply is 1950W, and the power of the low frequency power supply is 750W. The...

Embodiment 2

[0069] 1. Clean and pre-treat the pre-fabricated silicon wafers to obtain the damaged silicon wafers;

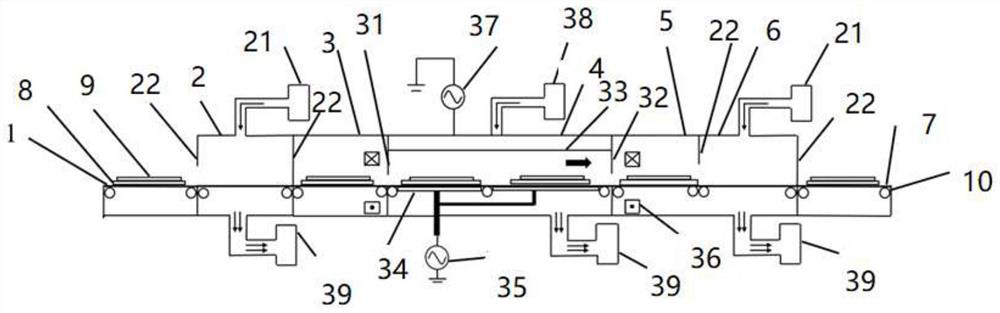

[0070] 2. Put the damaged silicon wafer on the carrier plate of the loading table of the reactive ion etching equipment. The reactive ion etching equipment such as figure 1 As shown, it includes a loading table, a loading chamber, a process buffer chamber, a process chamber, an unloading buffer chamber, an unloading chamber, an unloading table, a base, and a conveying system. Driven by the transmission rollers, the carrier board passes through the loading chamber and the process buffer chamber of the reaction ion equipment in turn, and enters the process chamber;

[0071] 3. Turn on the vacuuming equipment until the predetermined vacuum value is 0.5Pa, and enter the SF from the process air intake equipment 6 , O 2 and SiCl 4 For etching gas, the gas flow rates are 1850sccm, 2900sccm and 1650sccm respectively. The magnetic field device is turned on, and the etching gas ent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com