Feeding bottle sterilizing and drying device for neonatology department

A technology of neonatology and drying device, which is applied in the direction of household cleaning device, water supply device, cleaning device, etc., and can solve the problems of not being able to clean at the same time, remaining in the feeding bottle, and consuming energy to clean the feeding bottle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

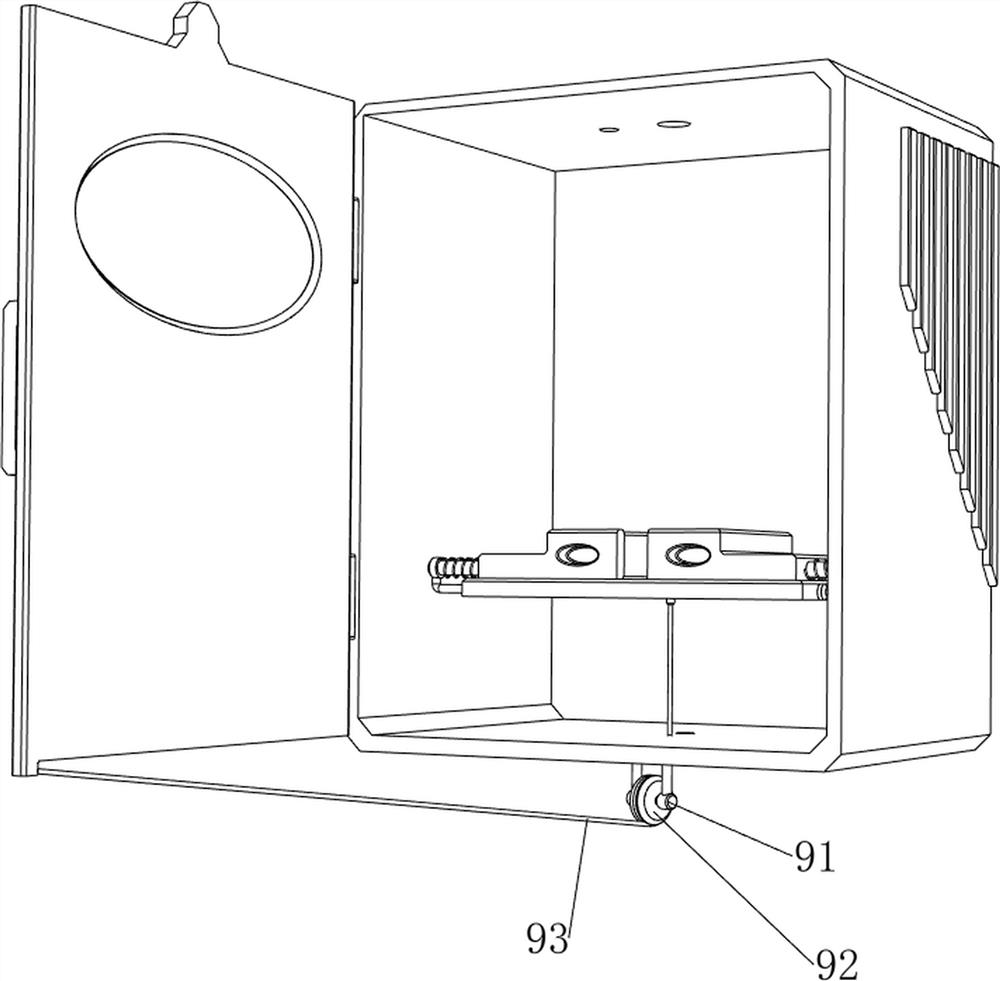

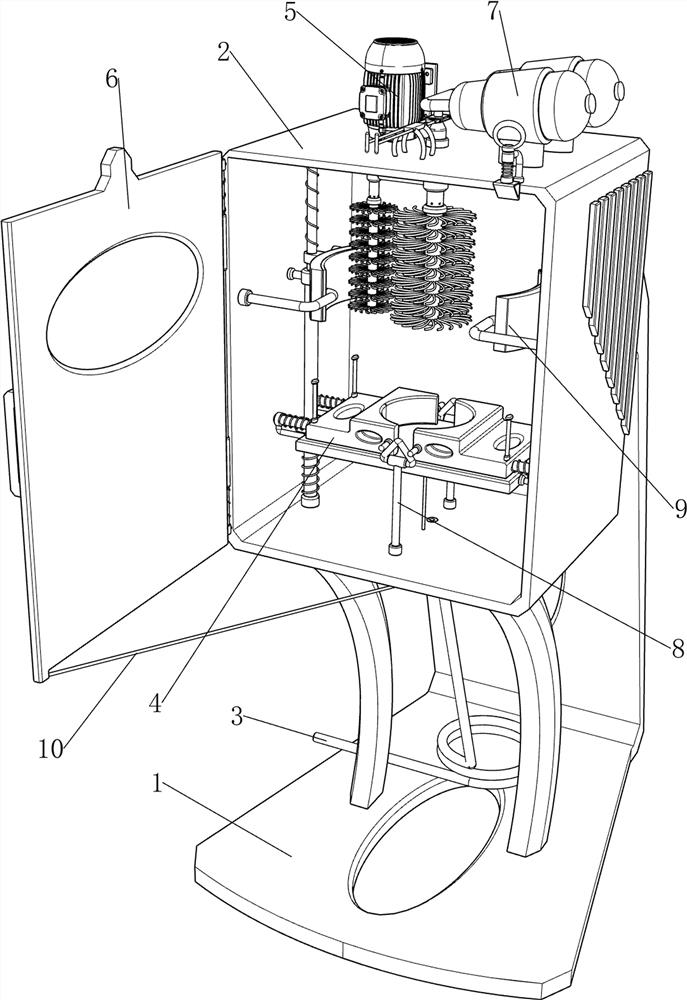

[0072] A baby bottle sterilization and drying device for neonatal department, such as Figure 1-3 As shown, it includes a foot 1, a box body 2, a first water outlet pipe 3, a clamping mechanism 4 and a scrubbing mechanism 5, a box body 2 is provided on the foot 1, a first water outlet pipe 3 is provided at the bottom of the box body 2, and the box body 2 is provided with a clamping mechanism 4, and the top of the box body 2 is provided with a scrubbing mechanism 5.

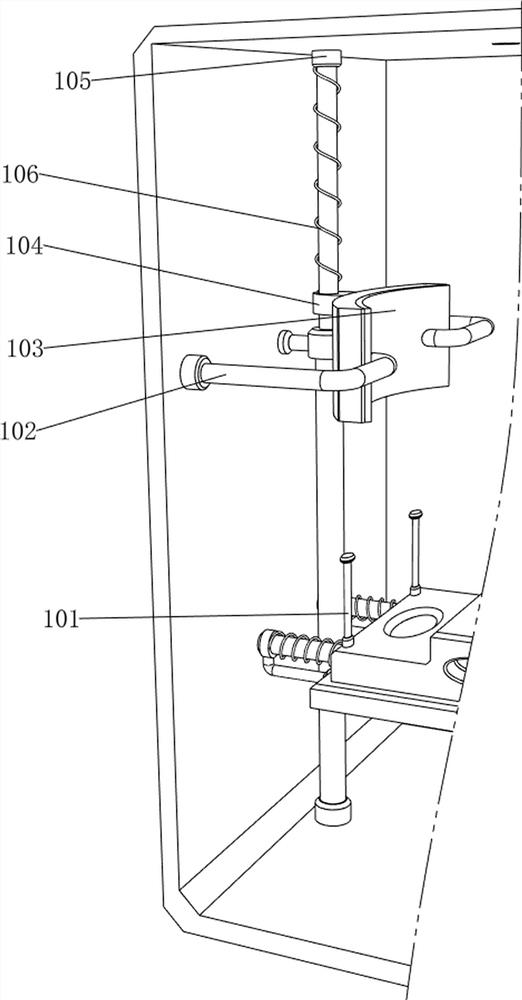

[0073]The clamping mechanism 4 includes a first slide bar 41, a first slide sleeve 42, a first spring 43, a second slide bar 44, a clip block 45 and a second spring 46, and the left and right sides of the inner wall of the box body 2 are provided with first Sliding bar 41, the first sliding sleeve 42 is slidably connected between the first sliding bar 41, the first spring 43 is arranged between the left and right sides of the bottom of the first sliding sleeve 42 and the first sliding bar 41 bottom, the first slid...

Embodiment 2

[0077] On the basis of Example 1, such as Figure 4-8 As shown, a blocking mechanism 6 is also included, and the blocking mechanism 6 includes a cylindrical rod 61, a first baffle plate 62, a handle block 63, a torsion spring 64, a second sliding sleeve 65, a locking rod 66 and a third spring 67, A cylindrical rod 61 is connected between the upper and lower sides of the left front part of the box body 2, and a first baffle plate 62 is rotatably connected to the cylindrical rod 61, and a torsion spring 64 is arranged between the upper and lower sides of the first baffle plate 62 and the cylindrical rod 61. , the left front side of the first baffle plate 62 is provided with a handle block 63, the right front side of the top of the box body 2 is provided with a second sliding sleeve 65, and the second sliding sleeve 65 is slidably connected with a clamping rod 66, and the lower part of the clamping rod 66 is connected to the A third spring 67 is connected between the second slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com