Constructional engineering perpendicularity detection device and detection method thereof

A detection device and construction engineering technology, which is applied in the direction of measuring device, surveying and mapping and navigation, measuring inclination, etc., can solve the problems of large overall volume, complex mechanism, and poor equipment use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

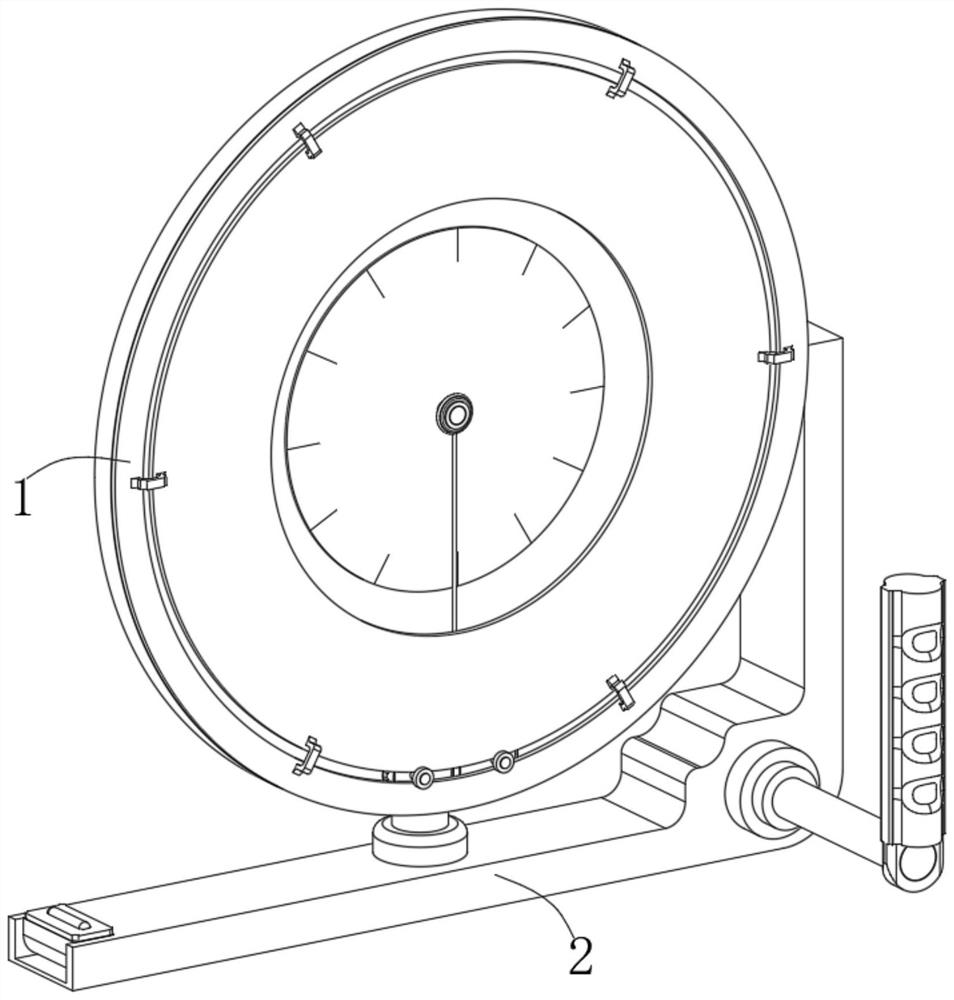

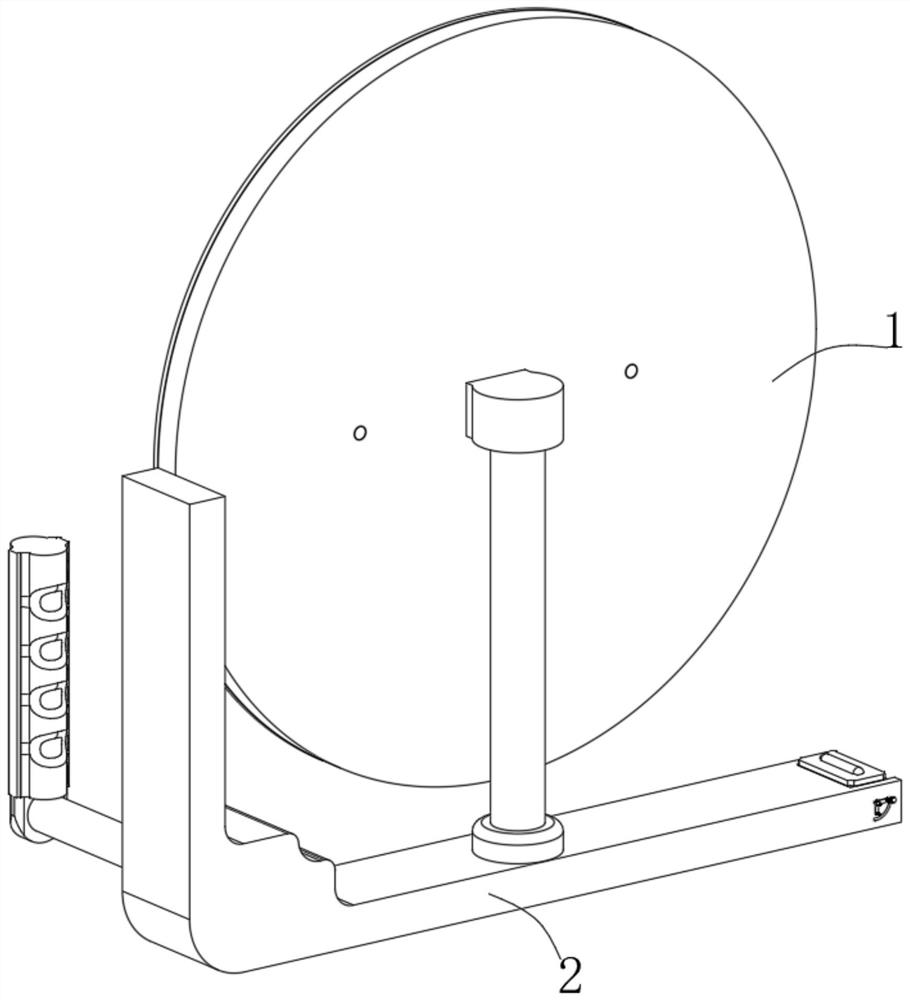

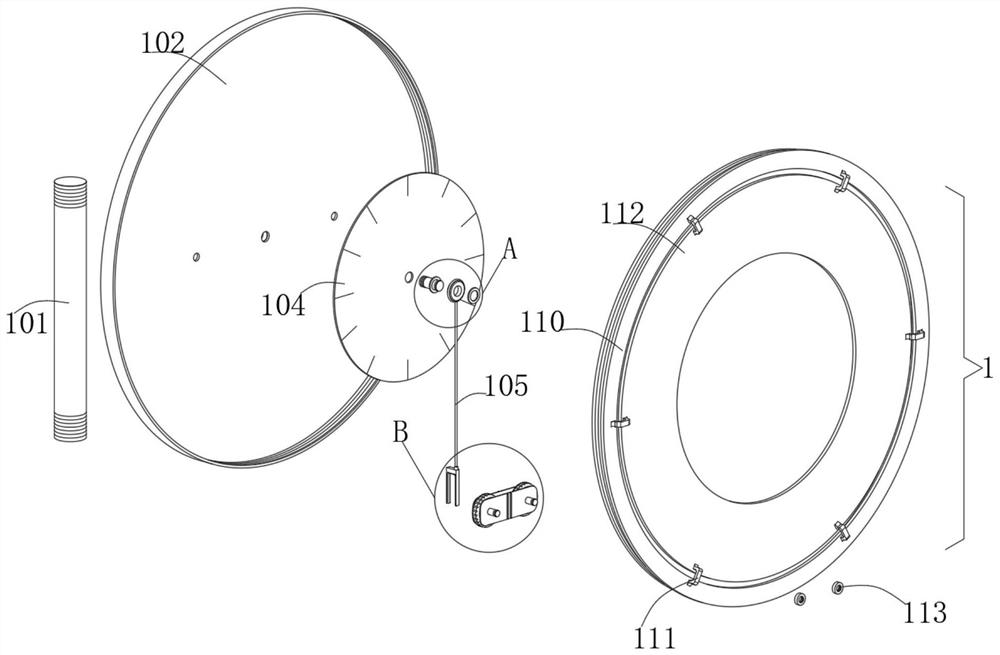

[0035] refer to Figure 1-8 , a construction engineering verticality detection device, comprising: a support mechanism 2, the support mechanism 2 includes a right-angle base 201, the establishment of the right-angle base 201 provides the installation basis for other functional components of the equipment, and the top center of the right-angle base 201 is provided with a connection threaded hole , the establishment of the connecting threaded hole is convenient for the installation and setting of the support rod 101, the outer surface of the right-angle base 201 is provided with a moving groove near the edge of the front side, and the establishment of the moving groove is convenient for the installation and setting of the moving rod 203, and the measuring mechanism 1, The measuring mechanism 1 includes a support rod 101 and a counterweight component. The establishment of the support rod 101 cooperates with the right-angle base 201 to effectively connect the measuring mechanism 1 ...

Embodiment 2

[0037] refer to Figure 3-8, the top of the right-angle base 201 is provided with an installation slot near the center of the front edge. The establishment of the installation slot is convenient for the installation and setting of other functional components of the equipment. The two sides of the installation slot are fixedly connected to the center of the inner surface wall. The establishment of the shaft is convenient for the installation and setting of the steering block 202. The support mechanism 2 also includes a leveling component. The leveling component includes the steering block 202. The establishment of the steering block 202 is convenient for the installation and setting of the bubble level body 208. The structure of the bubble level body 208 And the principle belongs to the prior art. In order to omit the space, it will not be described in detail here, and the model can be selected according to the actual equipment usage. The steering block 202 is slidably sleeved o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com