Crack Growth Monitoring and Reliability Evaluation System for Deep Sea Pipeline Based on Image Recognition

An evaluation system and image recognition technology, applied in image communication, closed-circuit television system, electrical transmission signal system, etc., can solve the limitations of crack image evaluation methods, do not consider the influence of pipeline cracks, and cannot achieve real-time evaluation, etc., to achieve The effect of improving monitoring efficiency, saving inspection time, and saving manpower and material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific structure and implementation process of this solution will be described in detail below through specific embodiments and accompanying drawings. In the following description, the historical pipeline refers to the pipeline whose working life is terminated after the crack occurs in the used deep-sea pipeline, and the crack image is captured and saved during its working process. The monitoring pipeline refers to the deep-sea pipeline currently in use, and its crack images are acquired in real time.

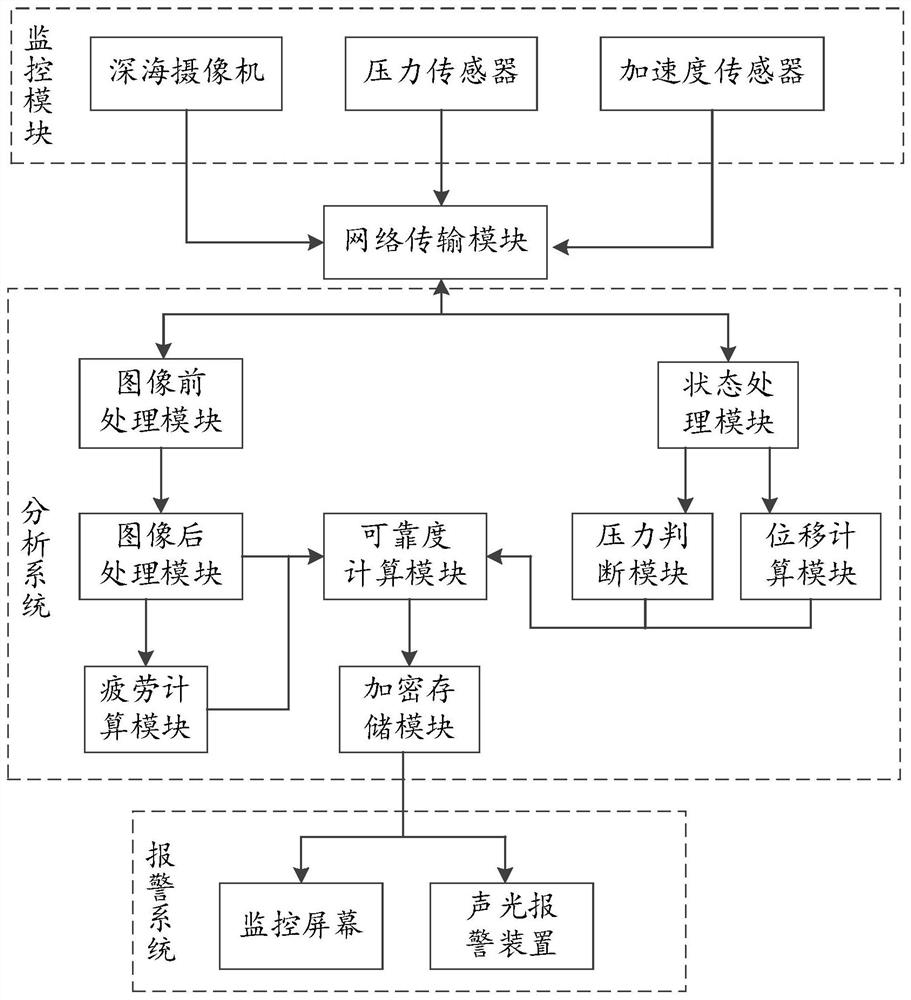

[0014] like figure 1 As shown, in one embodiment of the present invention, a deep-sea pipeline crack propagation monitoring and reliability assessment system based on image recognition is provided, including monitoring equipment, a network transmission module, an analysis system and an alarm system.

[0015] The monitoring equipment is used to obtain the changing parameters of the monitoring pipeline, including a deep-sea camera distributed around the monitoring p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com