Garbage classification throwing system and method

A garbage classification and garbage technology, which is applied in trash cans, garbage collection, sorting, etc., can solve the problems of flying insects and flies, occupying cultivated land, overflowing sewage, etc., and achieves the effect of convenient daily use and convenient management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

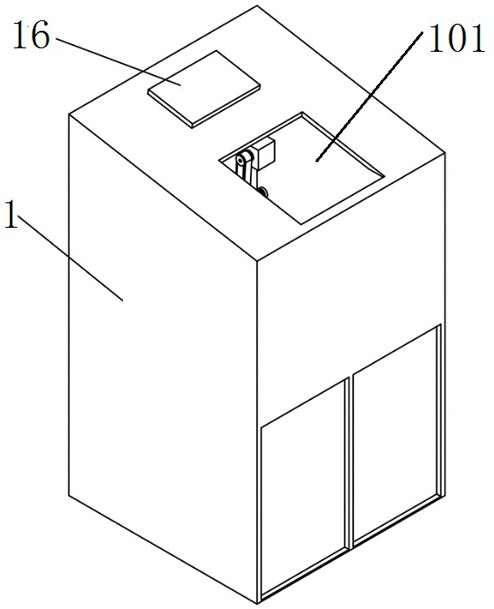

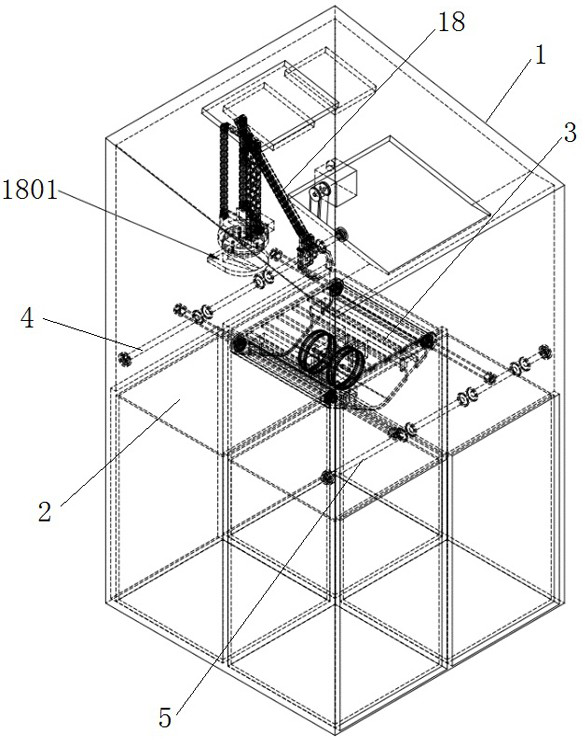

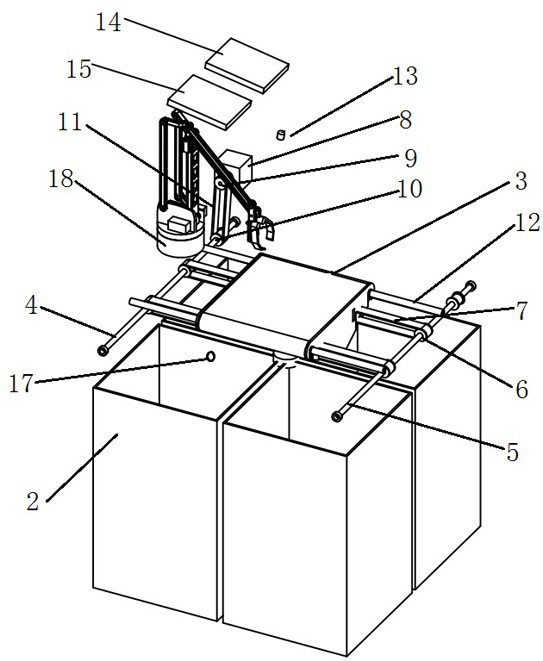

[0027] Embodiment 1: as Figure 1~3 As shown, a garbage sorting system includes a box body 1 and a number of garbage cans 2 arranged in the box body 1. The outer wall of the box body 1 is provided with an opening for taking out and putting in the garbage cans 2, and a box door is arranged at the opening position. The top of the casing 1 is provided with a delivery port 101, and a conveyor 3 is provided below the delivery port 101. The conveyor 3 is connected with a moving mechanism, and the moving mechanism includes a first synchronous shaft 4 and a second synchronous shaft installed in the casing 1 through bearing rotation. Two synchronous shafts 5, the first synchronous shaft 4 and the second synchronous shaft 5 are provided with a synchronous wheel 6, the synchronous wheel 6 is driven by a synchronous belt 7, the conveyor 3 is connected with the synchronous belt 7, and the transmission direction of the conveyor 3 is in line with the synchronous The conveying direction of th...

Embodiment 2

[0037] Embodiment 2: Different from Embodiment 1, it includes a camera 13, a control board 14, a processing board 15 and a display screen 16. The display screen 16 is arranged on the outside of the casing 1, and the display screen 16 is electrically connected to the control board 14. The camera 13 It is electrically connected with the processing board 15 and the control board 14 in turn, and the control board 14 controls the opening and closing of the conveyor 3 and the driving mechanism.

[0038] The garbage thrown in can be photographed by the camera 13, and after the image processing is carried out by the processing board 15, it is sent to the control board 14, and the control board 14 realizes automatic throwing of the garbage by operating the conveyor 3 and the driving mechanism.

[0039] Preferably, an infrared detector 17 is provided on the upper part of the trash can 2 , and the infrared detector 17 is electrically connected with the control board 14 .

[0040] Infrare...

Embodiment 3

[0043] Embodiment 3: different from Embodiment 2, such as figure 2 , image 3 and Figure 6 As shown, a mechanical arm 18 is arranged inside the box body 1 , and the mechanical arm 18 is electrically connected to the control board 14 .

[0044] By arranging the mechanical arm 18, the garbage on the conveyor 3 can be grabbed and dropped.

[0045] Preferably, the mechanical arm 18 includes a mounting plate 1801 connected to the box body 1, the mounting plate 1801 is provided with a lower platform 1802, and the lower platform 1802 is provided with a first steering gear 1804 for controlling the rotation of the upper platform 1803, The upper cloud platform 1803 is provided with a second steering gear 1806 for controlling the movement of the arm group 1805, the end of the arm group 1805 is provided with a connecting plate 1807, and the connecting plate 1807 is provided with a gripper 1808 and a third steering gear for controlling the gripper 1808 1809.

[0046] During concrete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com