Mobile phone shell die punching equipment for batch use

A mobile phone case and punching die technology, applied in metal processing and other directions, can solve the problems of labor consumption and low work efficiency, and achieve the effect of reducing manual manual operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

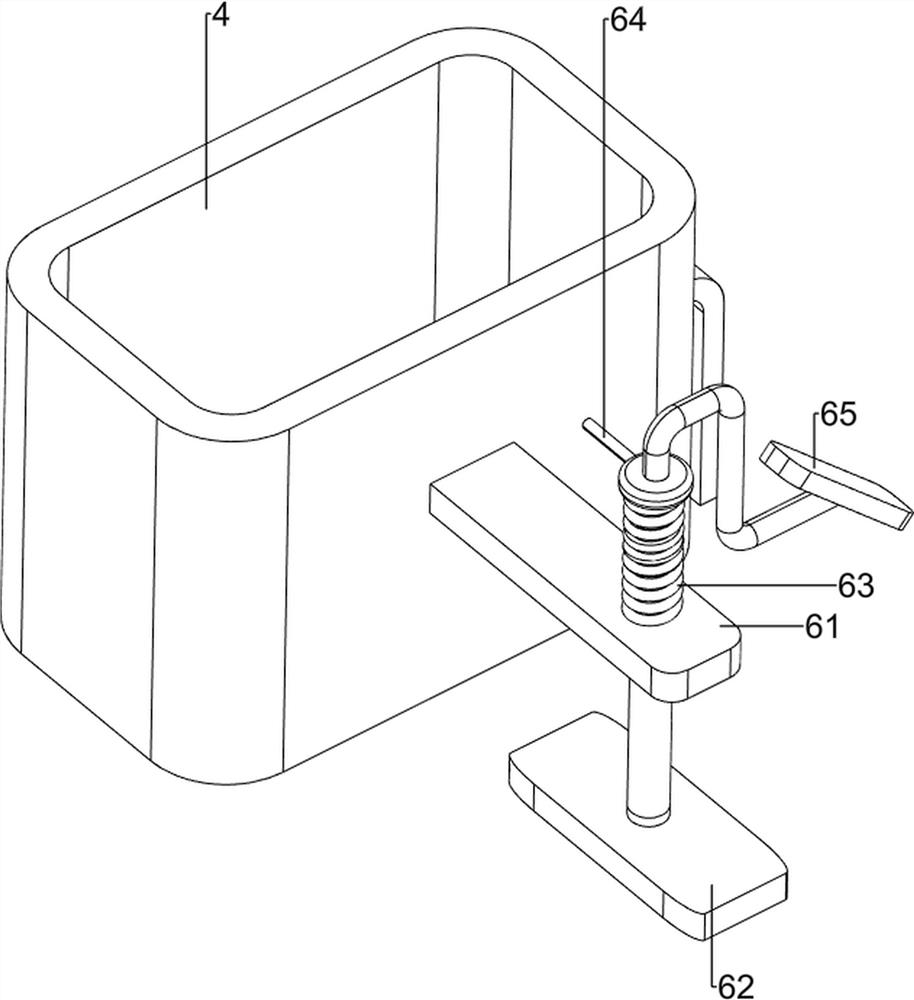

[0067] A batch with mobile phone shell die equipment, such as figure 1As shown, including a first support plate 1, a first support frame 2, a second support plate 3, a discharge frame 4, a push mechanism 5, a lower pressure mechanism 6, a die mechanism 7, and a gear mechanism 8, and the first support. The plate 1 is uniformly provided with four first support frames 2, and there is a second support plate 3 between the four first support frames 2, and the second support plate 3 is provided with a discharge frame 4. The bottom pressure mechanism 6 is provided with a lower pressure mechanism 6 in the right portion of the discharge frame 4, and the lower pressure mechanism 6 is provided with a die mechanism 7, and the front side of the discharge frame 4 is provided with a block. Bit mechanism 8.

[0068] When people need to furnish the mobile phone case, this batch can be used with mobile phone shell molding equipment. First, people need to furnish the mobile phone shell in the dischar...

Embodiment 2

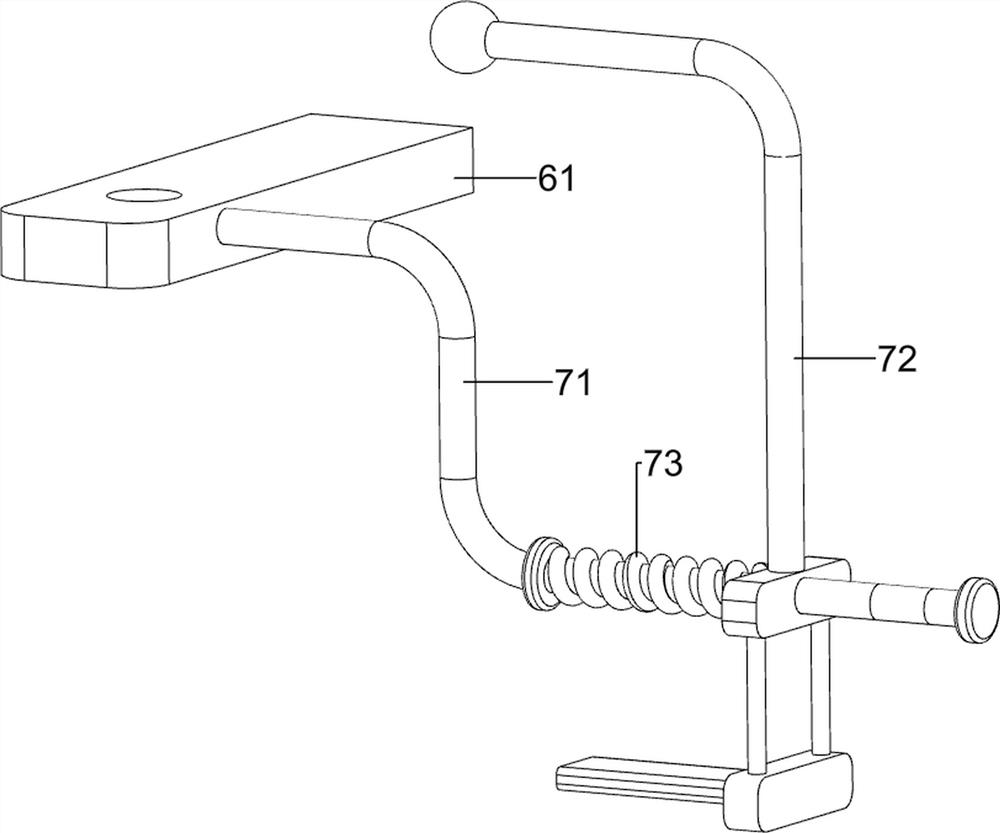

[0070] On the basis of Example 1, such as Figure 2-5 As shown, the pince material 5 includes a first fixing lever 51, a pincer 52, a first spring 53, and a first circumferential rod 54, and the front pressure mechanism 6 is provided with a first fixing bar 51, and the first fixing rod. 51 Sliding is provided with a pince 52, and the first fixing rod 51 is connected between the pincers 52, and the first spring 53 is wound around the pincer 52, and the front side of the pincer 52 is provided. The first round block 54.

[0071] After placing the mobile phone case into the discharge frame 4, manually move the first round block 54 to the right, so that the pincerifer 52 is moved to the right, the first spring 53 is compressed, and when the pins 52 drives the phone shell to the right When moving to the lower pressure mechanism 6, that is, the effect of the pins 52 pushes the mobile phone case, and then people release the first round block 54 so that the first spring 53 drives the first ...

Embodiment 3

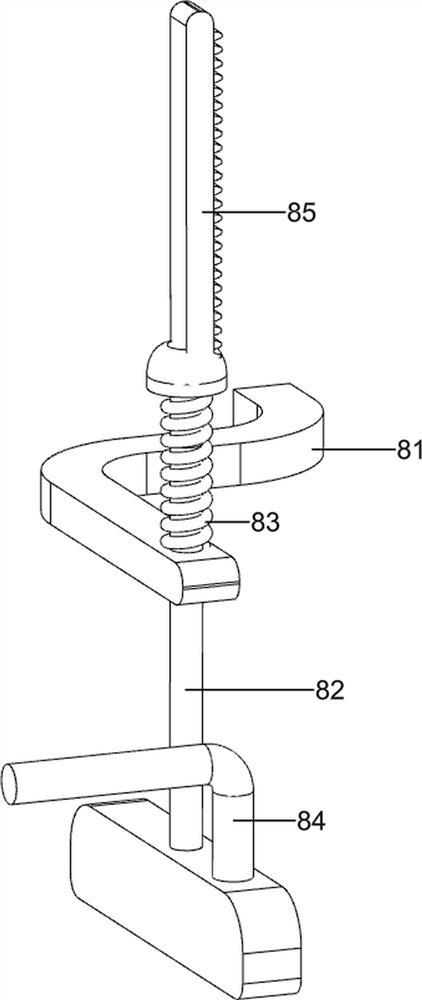

[0079] On the basis of Example 2, such as Figure 6-8 The first auxiliary mechanism 9 includes a first auxiliary mechanism 9 including a first fixing frame 91, auxiliary rod 92, and a fifth spring 93. The first fixing rod 51 is provided with a first fixing frame 91, The fixing frame 91 is slidably equipped with auxiliary rod 92, and the second fixing shaft 84 and the first round block rod 54 are fitted to the auxiliary rod 92, and the second spring 93 is connected to the first fixing frame 91. The fifth spring 93 is wound around the auxiliary rod 92.

[0080] The first round block 54 moves the auxiliary rod 92 to the right movement, the fifth spring 93 is compressed, and the second fixing shaft 84 is moved upward, the stopper 82 and the first rack 85 move, the fourth spring 83 is stretched, and people manually move the lower pressure mechanism 6, so that the die mechanism 7 moves backward, the first round block rod 54 is reset to the left, and the fifth spring 93 drives the auxilia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com