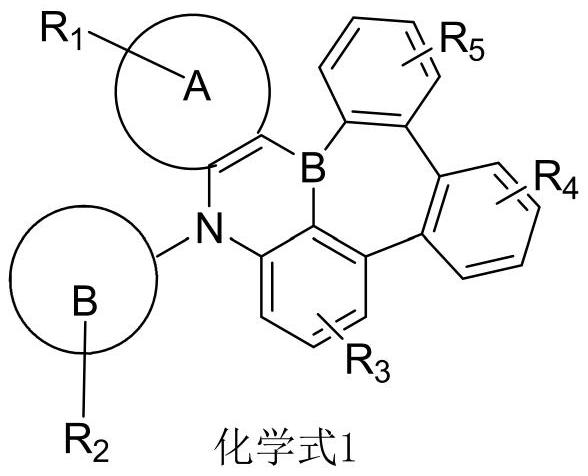

Organic compound doped material as well as preparation method and application thereof

A technology of organic compounds and doping materials, applied in the field of organic light-emitting materials, can solve problems such as aggravation of phenomena, dopant concentration quenching, lack of interaction strength, etc., to achieve increased stability, excellent characteristics, and excellent electrochemical stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

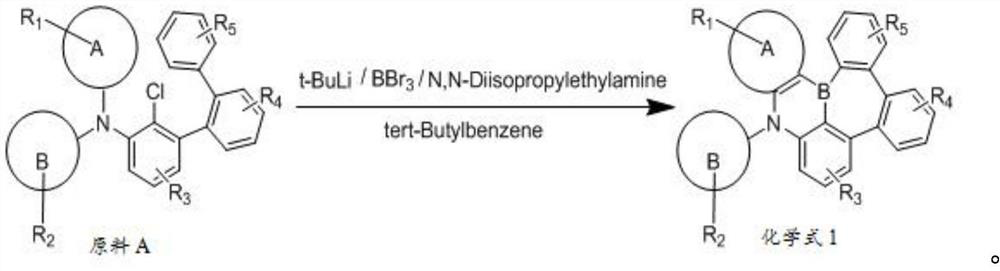

[0049] Embodiment 1: the preparation of compound B001:

[0050]

[0051] After 20 g of starting material B001-1 (41.49 mmol) was dissolved in tert-butylbenzene (300 mL), it was cooled to 0° C., and 8 mL of tert-butyllithium (tert-butyllithium) was added under a nitrogen atmosphere. ) solution (inPentane: in pentane) 82.99mmol), and stirred at 60°C for 1 hour, after which, the reaction was cooled to -20°C again, and 7.85mL of BBr was added 3 (82.99mmol), stirred at room temperature for 1 hour, the reactant was cooled to -20°C again, and 13.75mL of N,N-diisopropylethylamine (N,N-diisopropylethylamine) (82.99mmol) was added, and Stir at 60°C for 5 hours, TLC detection, the reaction is complete, the reaction solution is cooled to room temperature, ethyl acetate and water are added to extract the organic layer, dried over anhydrous sodium sulfate, the filtrate is spin-dried, and silica gel column chromatography (DCM / PE) Purified by using the method, and then recrystallized and ...

Embodiment 2

[0052] Embodiment 2: the preparation of compound B022:

[0053]

[0054] After 20 g of starting material B022-1 (31.04 mmol) was dissolved in tert-butylbenzene (300 mL), it was cooled to 0° C., and 6 mL of tert-butyllithium (tert-butyllithium) was added under a nitrogen atmosphere. ) solution (inPentane: in pentane) (62.08mmol) and stirred at 60°C for 1 hour, after which the reaction was cooled to -20°C again and 5.9mL of BBr 3 (62.08mmol), stirred at room temperature for 1 hour, the reactant was cooled to -20°C again, and 10.28mL of N,N-diisopropylethylamine (N,N-diisopropylethylamine) (62.08mmol) was added, and Stir at 60°C for 5 hours, TLC detection, the reaction is complete, the reaction solution is cooled to room temperature, ethyl acetate and water are added to extract the organic layer, dried over anhydrous sodium sulfate, the filtrate is spin-dried, and silica gel column chromatography (DCM / PE) Purified by using the method, and then purified by recrystallization wi...

Embodiment 3

[0055] Embodiment 3: the preparation of compound B048:

[0056]

[0057] After 20 g of starting material B048-1 (26.58 mmol) was dissolved in tert-butylbenzene (300 mL), it was cooled to 0° C., and 5.15 mL of tert-butyl lithium (tert- butyllithium) solution (inPentane: in pentane) (53.16mmol), and stirred at 60°C for 1 hour, after which, the reaction was cooled to -20°C again, and 5mL of BBr 3 (53.16mmol), stirred at room temperature for 1 hour, the reactant was cooled to -20°C again, and 8.8mL of N,N-diisopropylethylamine (N,N-diisopropylethylamine) (53.16mmol) was added, and Stirring at 60°C for 5 hours, TLC detection, the reaction was completed, the reaction solution was cooled to room temperature, ethyl acetate and water were added to extract the organic layer, dried over anhydrous sodium sulfate, the filtrate was spin-dried, and silica gel column chromatography (DCM / PE) Purified by using the method, and then purified by recrystallization with acetone solvent to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com