Asphalt construction device and method for road engineering

A technology of road engineering and construction equipment, which is applied in the field of asphalt construction, can solve the problems of inability to adjust the height of asphalt and lower construction quality, and achieve the effects of more uniform distribution of asphalt, reduced workload, and improved fluency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

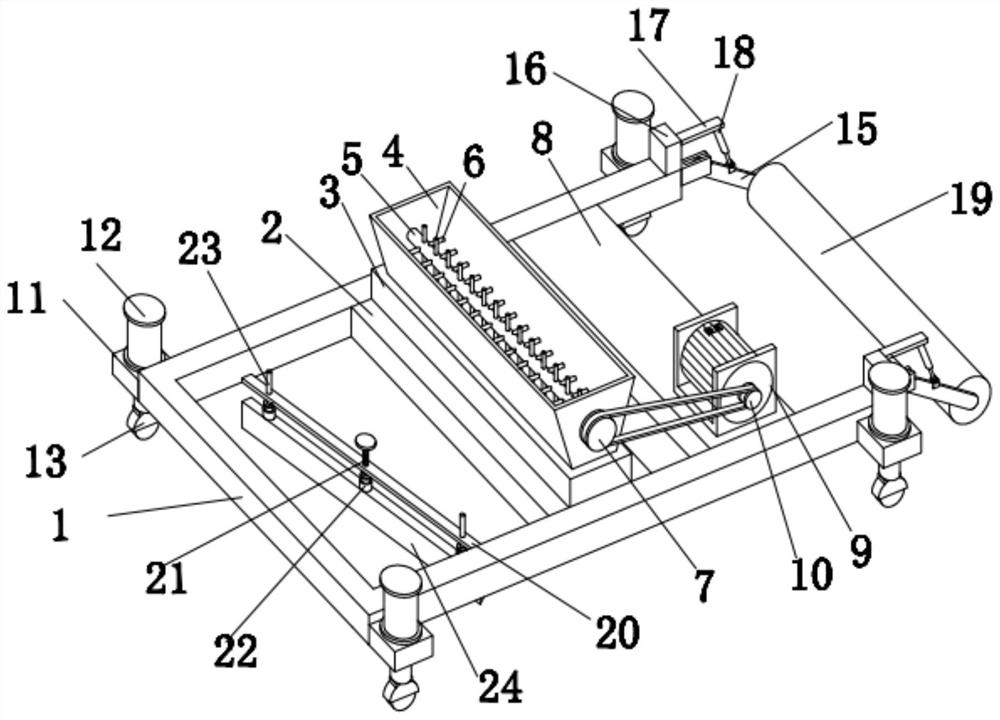

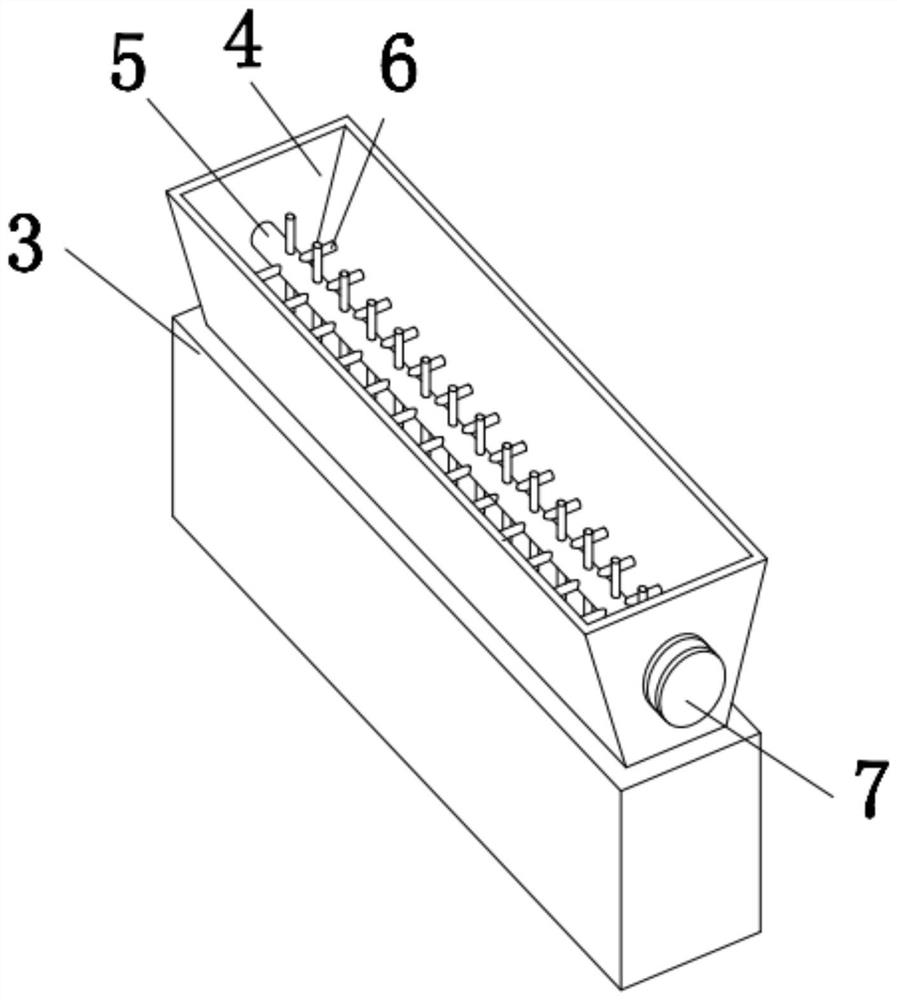

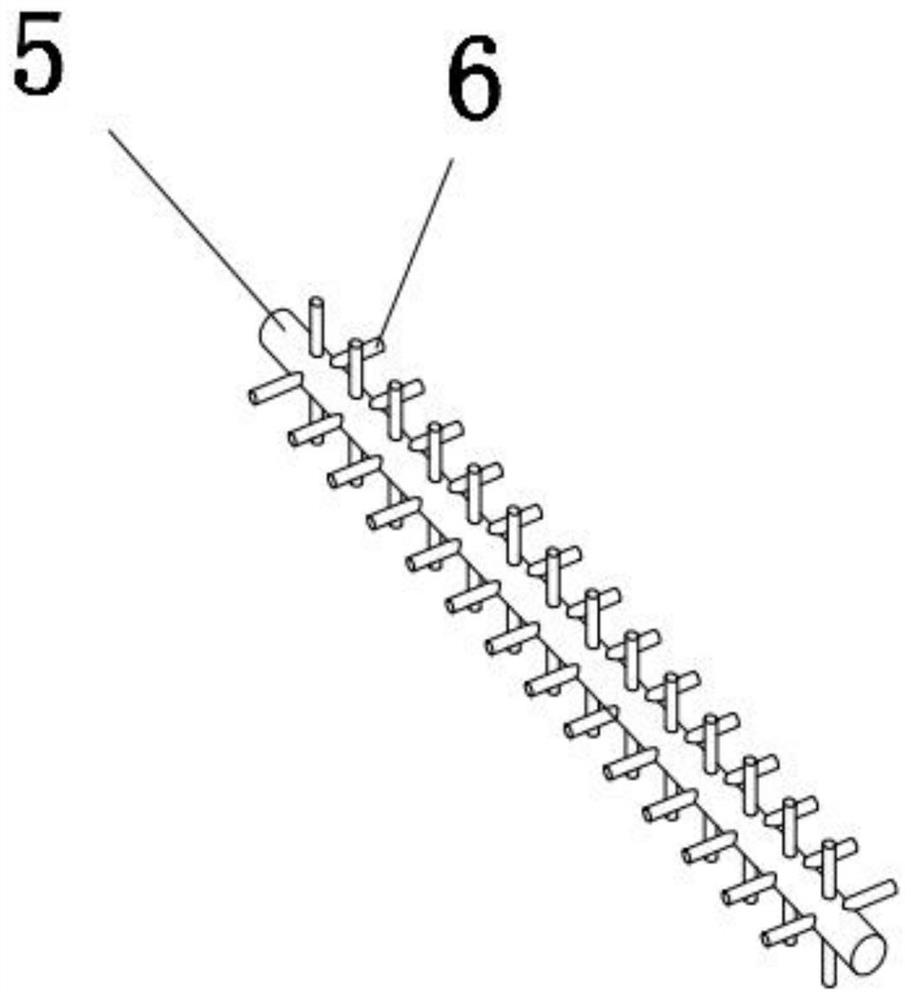

[0038] The present invention provides a kind of asphalt construction device for road engineering here through improvement, as Figure 1-Figure 5As shown, including the fixed shell 1, the outer walls on both sides of the fixed shell 1 are welded with support blocks 11 near the four corners, and the telescopic oil cylinder 12 is installed on the top outer wall of the support block 11 through bolts. The model of the telescopic oil cylinder 12 is preferably yxyg-01 , the outer wall of the bottom of the telescopic oil cylinder 12 is connected with a universal wheel 13 through bearing rotation, and the universal wheel 13 is used to facilitate the movement of the rotating device. There are two fixed bars 2 welded inside the fixed shell 1, and the inside of the fixed bar 2 is connected by bolts. A guide housing 3 is installed, and a hopper 4 is welded on the outer wall of the top of the guide housing 3, and the inside of the hopper 4 is connected to the stirring shaft 5 through bearing...

Embodiment 2

[0054] The present invention provides a kind of asphalt construction device for road engineering here through improvement, as Figure 1-Figure 5 As shown, including the fixed shell 1, the outer walls on both sides of the fixed shell 1 are welded with support blocks 11 near the four corners, and the telescopic oil cylinder 12 is installed on the top outer wall of the support block 11 through bolts. The model of the telescopic oil cylinder 12 is preferably yxyg-01 , the outer wall of the bottom of the telescopic oil cylinder 12 is connected with a universal wheel 13 through bearing rotation, and the universal wheel 13 is used to facilitate the movement of the rotating device. There are two fixed bars 2 welded inside the fixed shell 1, and the inside of the fixed bar 2 is connected by bolts. A guide housing 3 is installed, and a hopper 4 is welded on the outer wall of the top of the guide housing 3, and the inside of the hopper 4 is connected to the stirring shaft 5 through bearin...

Embodiment 3

[0070] The present invention provides a kind of asphalt construction device for road engineering here through improvement, as Figure 1-Figure 5 As shown, including the fixed shell 1, the outer walls on both sides of the fixed shell 1 are welded with support blocks 11 near the four corners, and the telescopic oil cylinder 12 is installed on the top outer wall of the support block 11 through bolts. The model of the telescopic oil cylinder 12 is preferably yxyg-01 , the outer wall of the bottom of the telescopic oil cylinder 12 is connected with a universal wheel 13 through bearing rotation, and the universal wheel 13 is used to facilitate the movement of the rotating device. There are two fixed bars 2 welded inside the fixed shell 1, and the inside of the fixed bar 2 is connected by bolts. A guide housing 3 is installed, and a hopper 4 is welded on the outer wall of the top of the guide housing 3, and the inside of the hopper 4 is connected to the stirring shaft 5 through bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com