Roof concrete pouring equipment

A technology of concrete and equipment, applied in the field of concrete pouring, can solve the problems of high cost of wood, inferior corrosion resistance to concrete structures, low concrete efficiency, etc., and achieve the effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

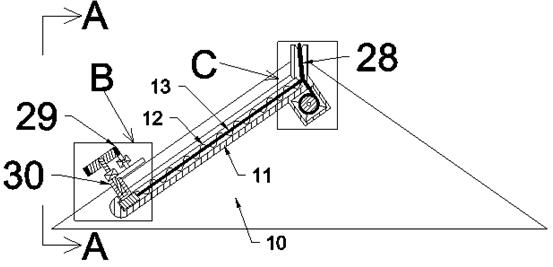

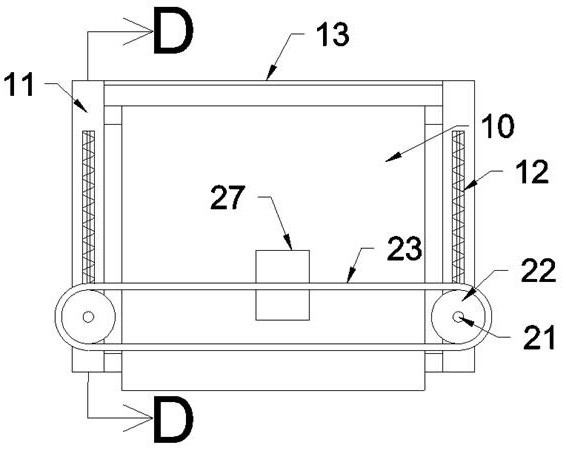

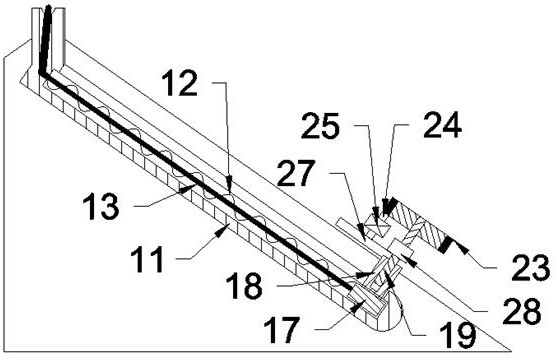

[0021] combined with Figure 1-6 In the roof concrete pouring equipment described above, the cooperation of the moving mechanism 28 and the smoothing mechanism 29 realizes smoothing the concrete on the upper end of the roof 10;

[0022] The moving mechanism 28 includes a slide rail 11 fixedly connected to the roof 10. There are two slide rails 11 in total. A synchronous motor 14 is embedded inside the slide rail 11 on one side. The synchronous motor 14 The synchronous motor shaft 15 is controlled, and the outer side of the synchronous motor shaft 15 is fixed with a rope winding wheel 16, and the outer side of the rope winding wheel 16 is wound with a synchronous stay rope 13, and the synchronous stay rope 13 is provided with two. The synchronous pull cord 13 is also fixedly connected with the synchronous slider 17 , the outer side of the synchronous slider 17 is fixedly provided with a compression spring 12 , and the synchronous slider 17 is slidably connected with the slide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com