A hand-held tool for tying steel bars

A technology for tying steel bars and tools, which is applied in the field of hand-held steel bar tying tools, and can solve problems such as damage to the spine and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

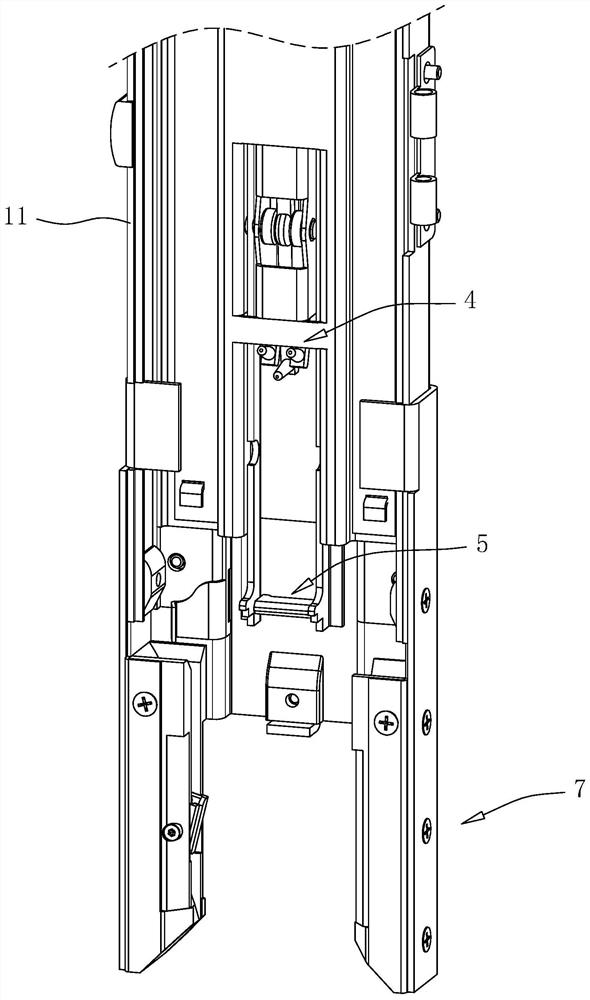

[0067] The following is attached Figure 1-18 The application is described in further detail.

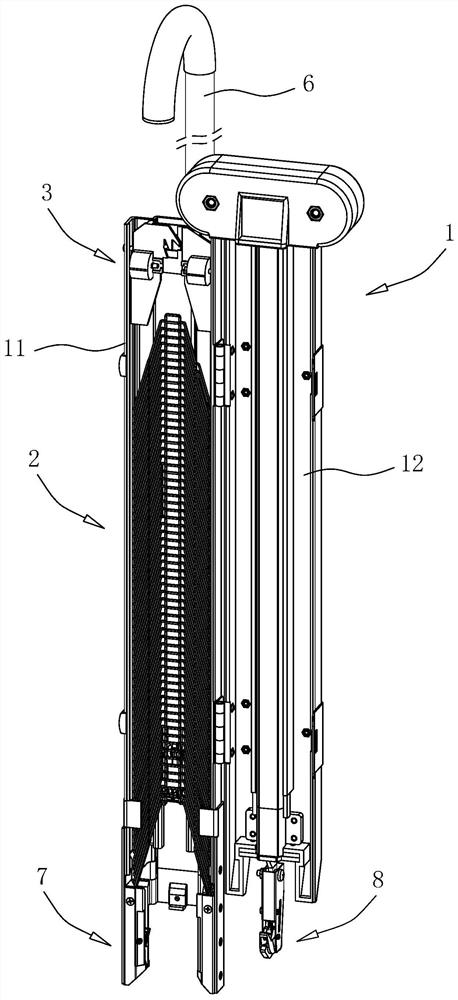

[0068] The embodiment of the present application discloses a hand-held tool for tying steel bars, and this embodiment is described in a vertical state of the hand-held tool for tying steel bars.

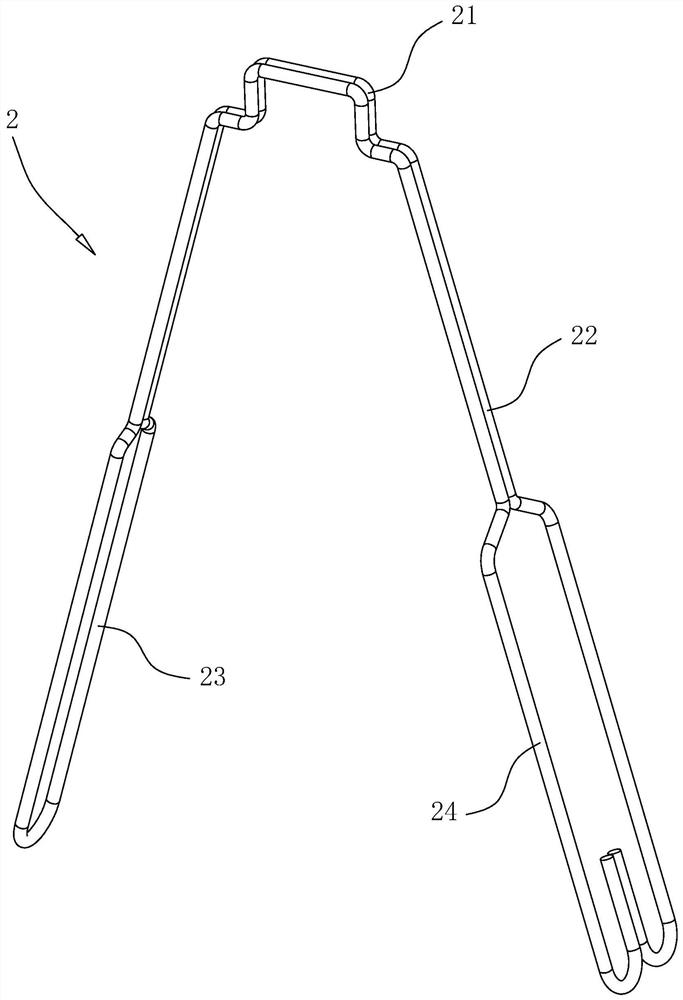

[0069] refer to figure 1 with figure 2 A hand-held tool for tying steel bars includes a storage box 1 that is vertically arranged and has an open bottom. The storage box 1 is divided into a feeding shell 11 and a winding shell 12 along the vertical direction. The sides of the volume shell 12 in the length direction are hinged, and between the feed shell 11 and the take-up shell 12, there is a buckle lock assembly 9 for fixing the two in a closed state to form the storage box 1; The threaded buttons 2 arranged in the vertical direction are all parallel to each other. The threaded buttons 2 include a force-bearing part 21, a winding part 22 fixed at both ends of the force-bearing part 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com