Novel efficient laser-driven micro compressor

A laser-driven compressor technology, applied in the field of compressors, can solve the problems of low transmission efficiency, inability to achieve continuous air intake, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

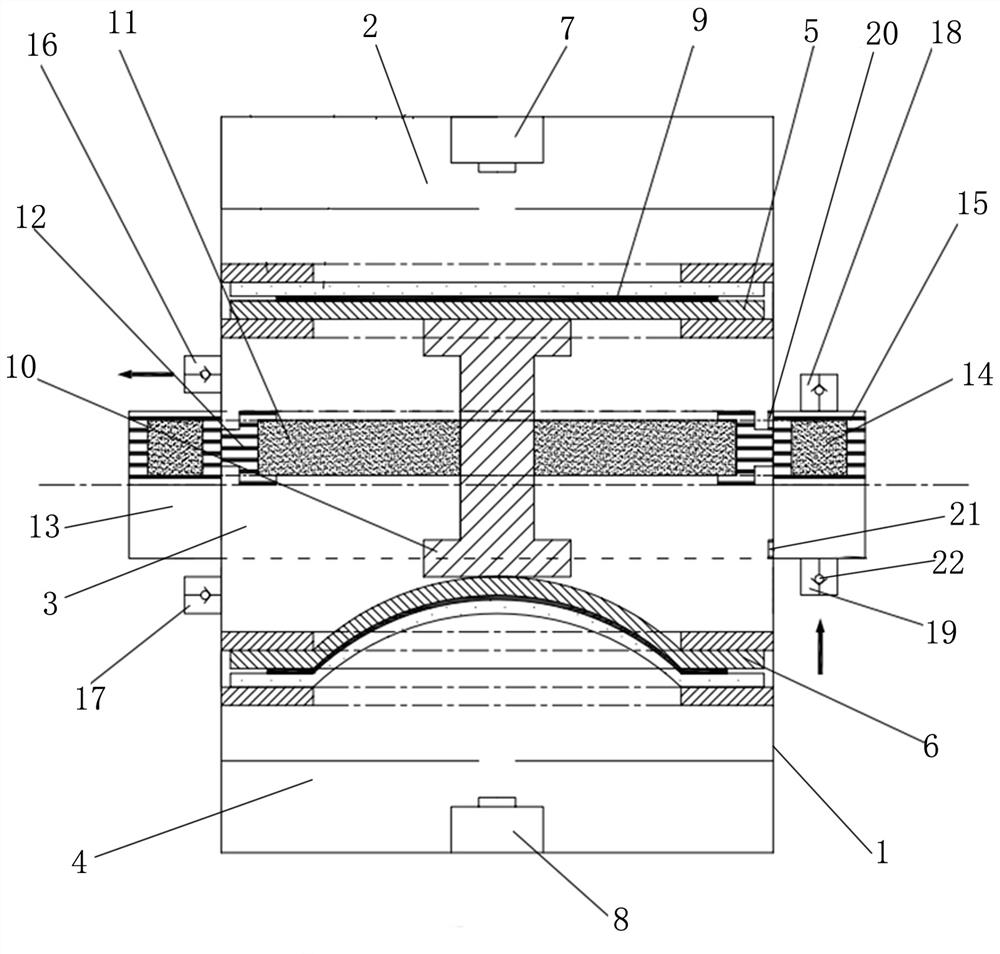

[0011] Further description will be made below in conjunction with the accompanying drawings.

[0012] figure 1 Shown: a new high-efficiency laser-driven micro-compressor, including a cylinder 1, an upper circular metal plate 5, a lower circular metal raised arc plate 6, an upper laser generator 7, a lower laser generator 8, a working Block 10, inner ring magnet 11, inner ring piston 12, suction ring cavity 13, outer ring magnet 14, outer ring piston 15. The cylinder body 1 is divided into upper drive chamber 2, compression chamber 3, and lower drive chamber 4 from top to bottom. The upper circular metal plate 5 is supported and crimped on the bottom of the upper drive chamber 2 and presses against the inner shape of the compression chamber 3. The upper end of the block 10 is supported by the lower round metal raised arc plate 6 and is crimped on the top of the lower drive chamber 4 and pressed against the lower end of the compression chamber 3 inner block 10, and the upper dr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap