Storage battery detection system

A detection system, battery technology, applied in signal transmission system, measurement power, measurement device, etc., to achieve the effect of saving labor cost, better effect, and saving supervision time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

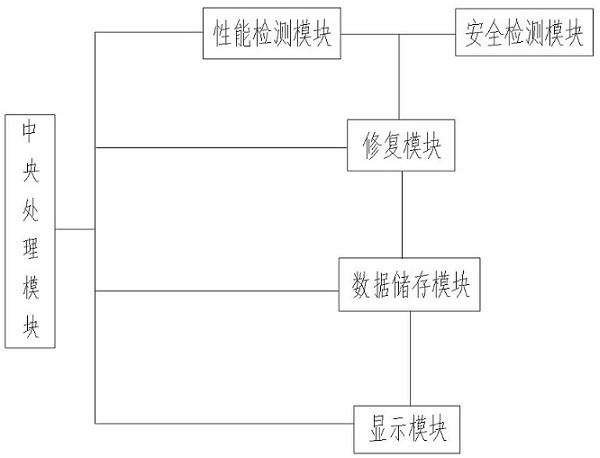

[0016] see figure 1 , a storage battery detection system, including a performance detection module, a safety detection module, a central processing module, a repair module, a data storage module and a display module; the performance detection module includes a current detection module and a time detection module, the central processing module and the performance detection module module, safety detection module, repair module, data storage module, and display module are electrically connected; the central processing module is used for controlling and statistical performance detection module, safety detection module, controlling the operation of each module, and statistical performance detection module , the quantity of batteries detected by the safety detection module and the quantity of batteries with detected quality problems.

[0017] The current detection module is used to detect the current coefficient during charging and discharging. The time detection module is used to d...

Embodiment 2

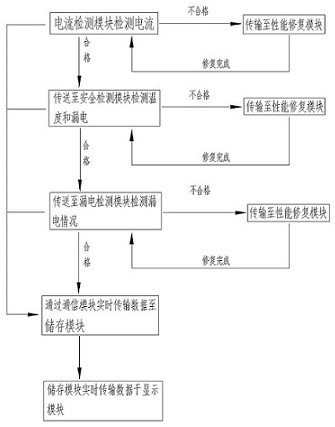

[0020] How the invention works: see figure 2 , the central processing module controls the performance detection module and the safety detection module to start, the current detection module in the performance detection module detects the current coefficient of the battery when charging and discharging, and when it is detected that the battery has no current or the current is unstable, the performance detection module sends a signal To the central processing module, the central processing module controls the performance repair module to repair the battery; the repaired battery is sent to the safety detection module, when the safety detection module detects battery leakage and overheated batteries, the safety detection module sends a signal to the central Processing module, the central processing module controls the performance repair module to repair the battery, and the time detection module starts to calculate the time required for battery charging and discharging. If the bat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com