Connecting structure of split type toner cartridge

A connection structure and split-type technology, which is applied to the electrical recording process using the charge pattern, the equipment of the electric recording process using the charge pattern, and the electrography, etc. It can solve the problems of affecting the printing effect, polluting the printed image, and high replacement costs. , to achieve the effect of avoiding toner spillage, low powder filling requirements and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

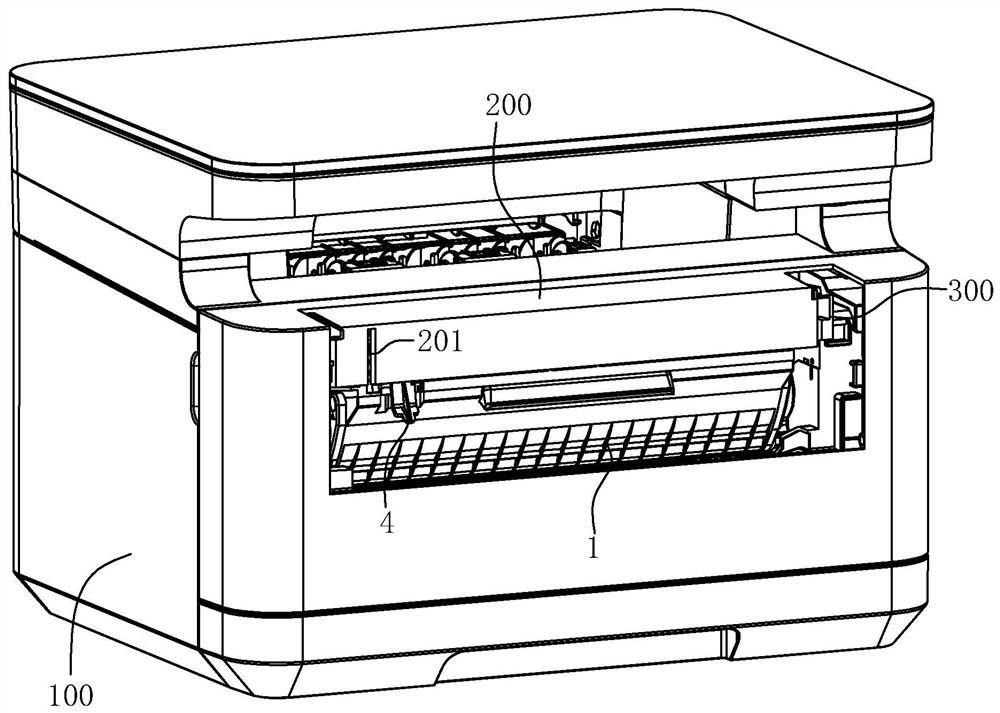

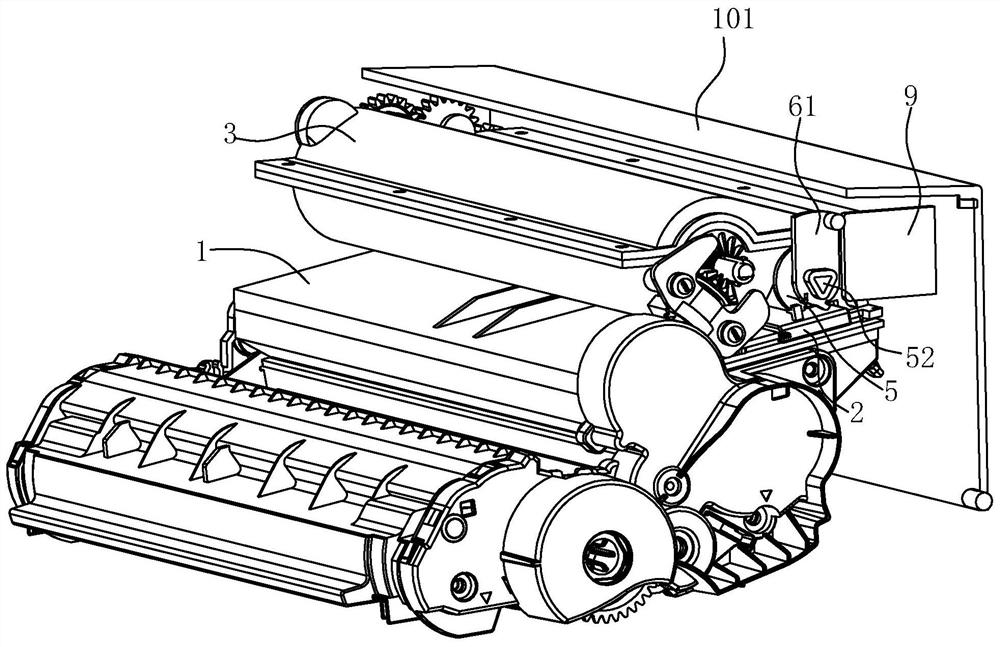

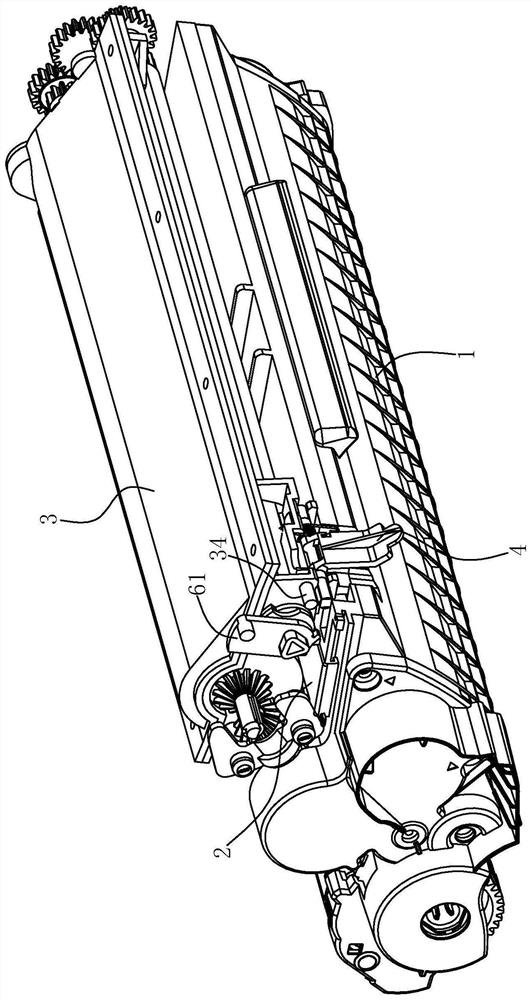

[0029] 1 to Figure 6 As shown, the connection structure of the split-type toner bin in this embodiment is set in the printer casing 100 having a cover plate 101, and the connection structure of the split-type toner bin includes a toner bin 1, a first cover 2, a toner A bin 3, a second cover 4, a powder outlet 5, a linkage 9, and a transmission mechanism 6.

[0030] Wherein the toner cartridge 1 is integrally connected to the toner cartridge body 10, and the toner cartridge body 10 is a toner cartridge assembly in the prior art, including components such as a photosensitive drum, a developing roller, a transfer roller, a charging roller, and the toner cartridge 1 communicates with the developing roller. , the toner in the toner chamber 1 can be evenly distributed on the developing roller under the action of the scraper.

[0031] In order to ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap