A non-uniform air gap structure to weaken the inherent shaft voltage of built-in permanent magnet motors

A uniform air gap, permanent magnet motor technology, applied in electrical components, magnetic circuits, electromechanical devices, etc., can solve the problems of generating loop shaft current, bearing damage, and weakening of the shaft voltage of the built-in permanent magnet synchronous motor, to ensure Mechanical strength, convenient processing technology, the effect of weakening the inherent shaft voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

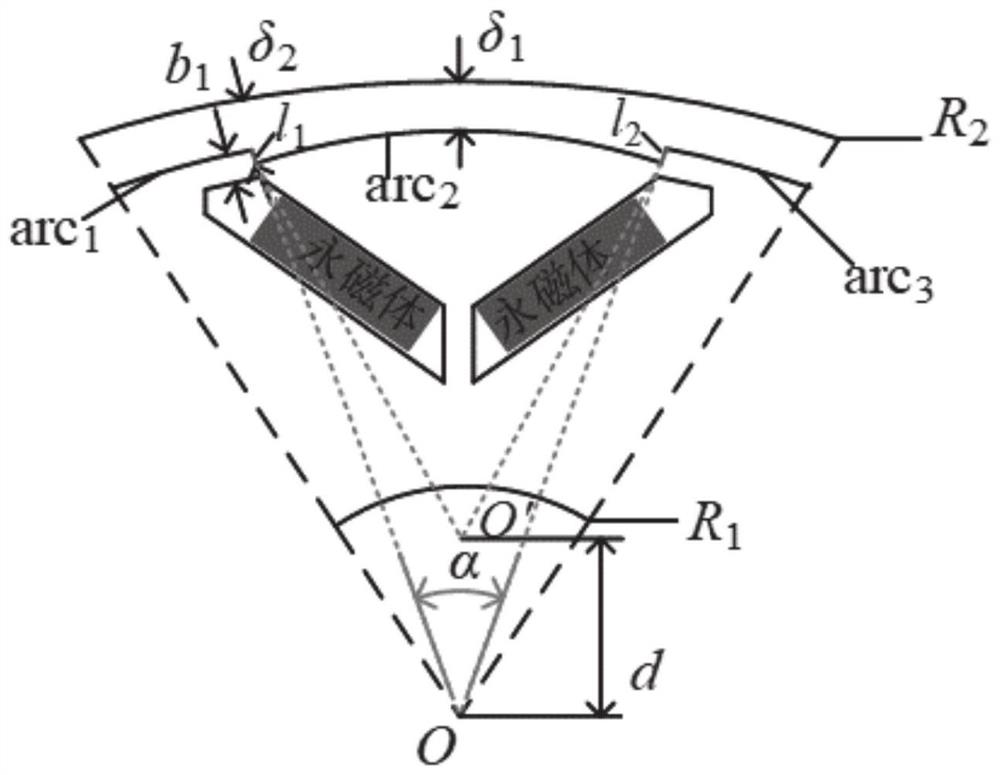

[0029] Embodiment 1 of the present disclosure provides a rotor non-uniform air gap structure that weakens the inherent shaft voltage of a built-in permanent magnet synchronous motor. Taking the built-in permanent magnet synchronous motor with a V-shaped rotor magnetic circuit structure as an example, the rotor non-uniform air gap structure like figure 1 shown.

[0030] In the figure, R 1 is the radius of the rotating shaft, R 2 is the inner diameter of the stator, δ 1 is the minimum air gap length, δ 2 is the maximum air gap length, arc 1 , arc 2 , arc 3 is an arc, l 1 , l 2 is line segment, arc arc 1 , arc 3 The corresponding center of the circle is O, that is, the center of the rotor circle of the uniform air gap structure, the arc arc 2 The corresponding center is O', d is the eccentricity, and α is the center angle corresponding to the permanent magnet slot.

[0031] The specific working principle is:

[0032] The size of the inherent shaft voltage of the buil...

Embodiment 2

[0044] Embodiment 2 of the present disclosure provides a built-in permanent magnet synchronous motor, including the non-uniform air gap structure for weakening the inherent shaft voltage of the built-in permanent magnet motor described in Embodiment 1 of the present disclosure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com