Raw material grinding equipment for solid beverage production

A technology of solid beverages and raw materials, applied in grain processing, etc., can solve problems such as troublesome, laborious, easy to be knocked down, occupying space, etc., and achieve the effect of easily unlocking the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

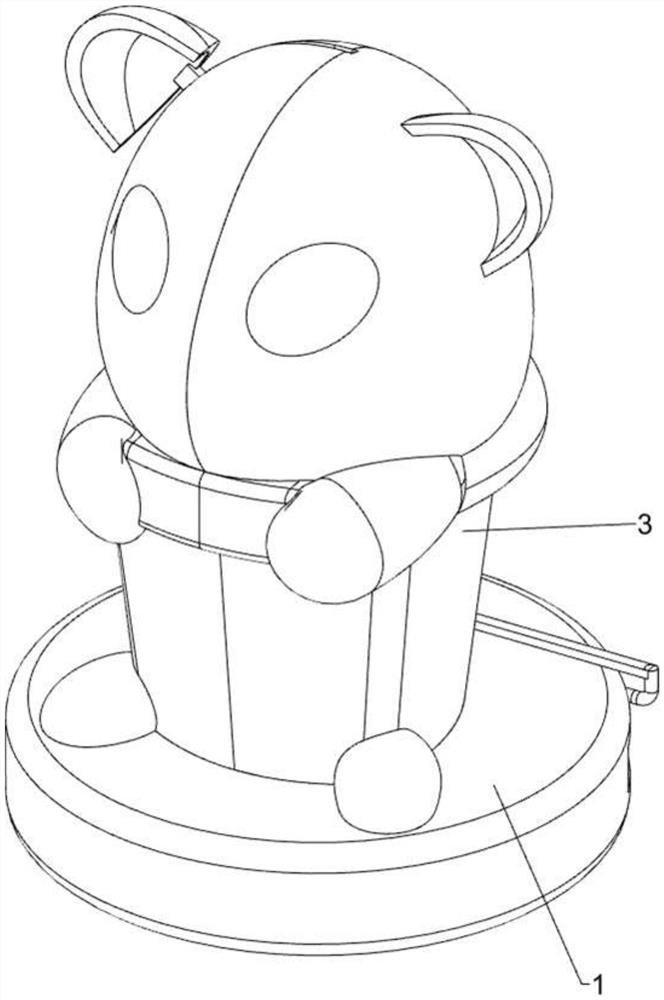

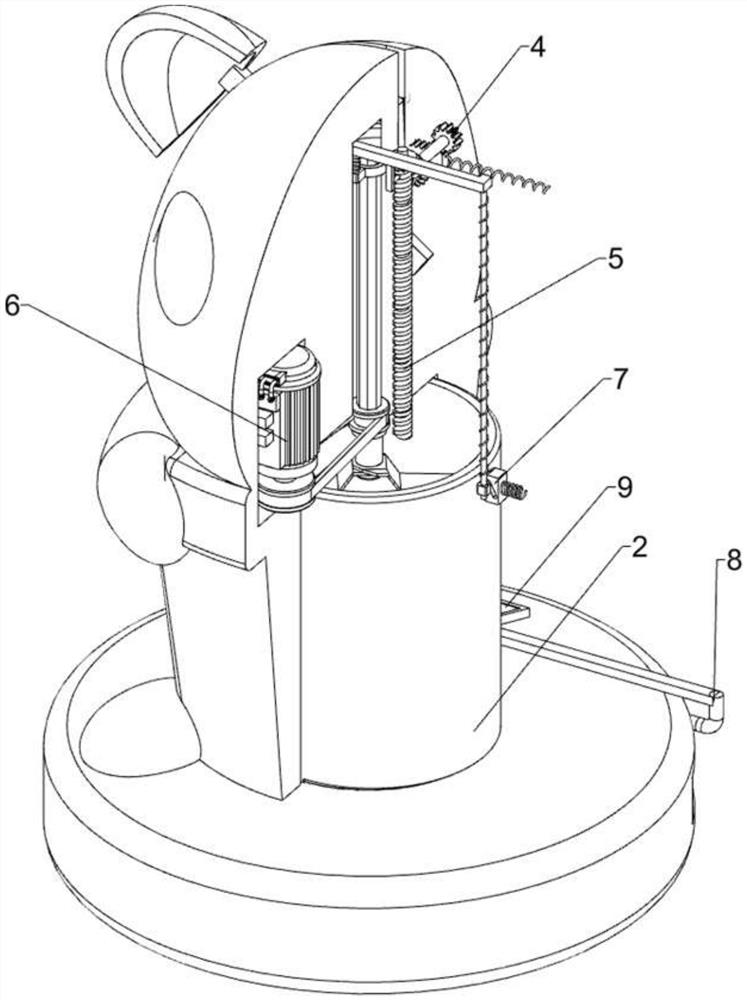

[0028] like Figure 1 to Figure 5 As shown, this embodiment discloses a raw material grinding equipment for solid beverage production, including a support plate 1, a placement cup 2, a housing 3, a drive mechanism 4, a lifting mechanism 5 and a grinding mechanism 6, and the upper middle of the support plate 1 is threaded Cooperate with a placement cup 2, the upper middle of the support plate 1 is covered with a housing 3, the placement cup 2 is located in the housing 3, the upper rear side of the housing 3 is provided with a driving mechanism 4, and the upper middle of the housing 3 is connected to the driving mechanism 4 A lifting mechanism 5 is arranged between them, and a grinding mechanism 6 is arranged between the front side of the middle part of the housing 3 and the lifting mechanism 5 .

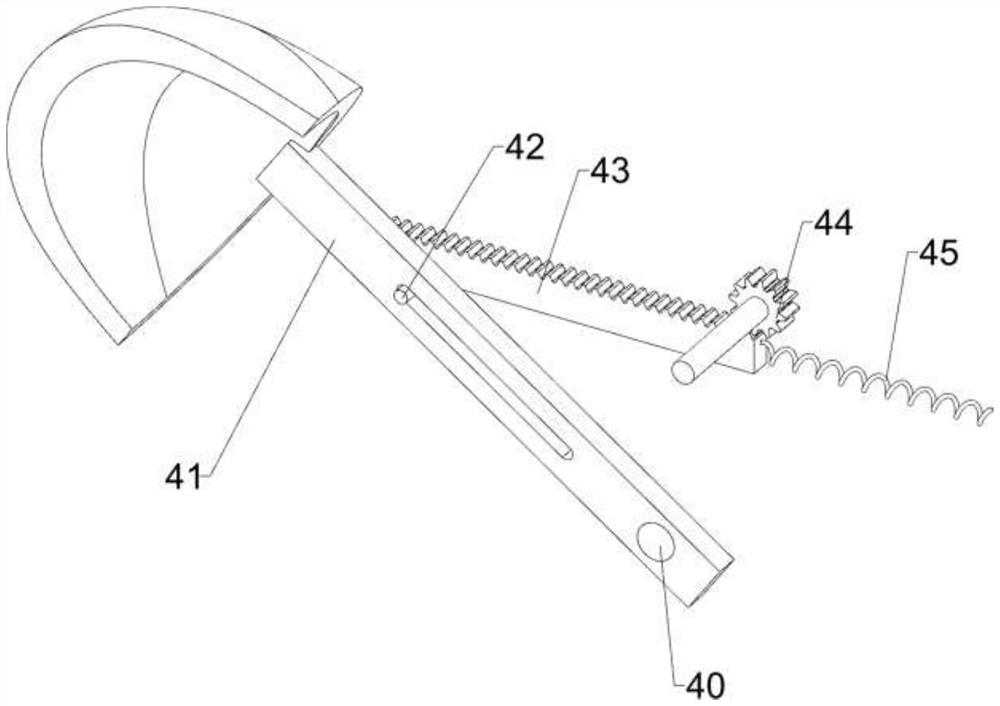

[0029] The driving mechanism 4 includes a first rotating shaft 40, a rotating rod 41, a slide bar 42, a rack 43, a first gear 44 and a first spring 45, and the upper rear side of the ...

Embodiment 2

[0034] Such as figure 2 , Figure 6 ~ Figure 9 As shown, in some embodiments, a clamping assembly 7 is also included. The clamping assembly 7 includes a guide rod 70, a third spring 71, a contact block 72, a clamping block 73 and a fourth spring 74. The lower part of the special-shaped rod 52 The left and right sides are connected with guide rods 70, and the lower side of the guide rods 70 is slidably connected with a contact block 72. A third spring 71 is connected between the contact block 72 and the special-shaped rod 52, and the third spring 71 is sleeved on the guide rod 70. Above, the left and right sides of the lower part of the housing 3 are slidably connected with clamping blocks 73, the clamping blocks 73 cooperate with the contact block 72 and the placement cup 2, and a fourth clamping block 73 is connected with the housing 3. spring 74.

[0035] When the special-shaped rod 52 moves downward, it will drive the guide rod 70 and the contact to move downward, thereb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com