Automatic cleaning method and system for gas pressure tapping pipe

A technology for automatic cleaning and pressure taking, which can be used in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., and can solve problems such as increased maintenance costs, personal injury, and impact on production efficiency and production quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

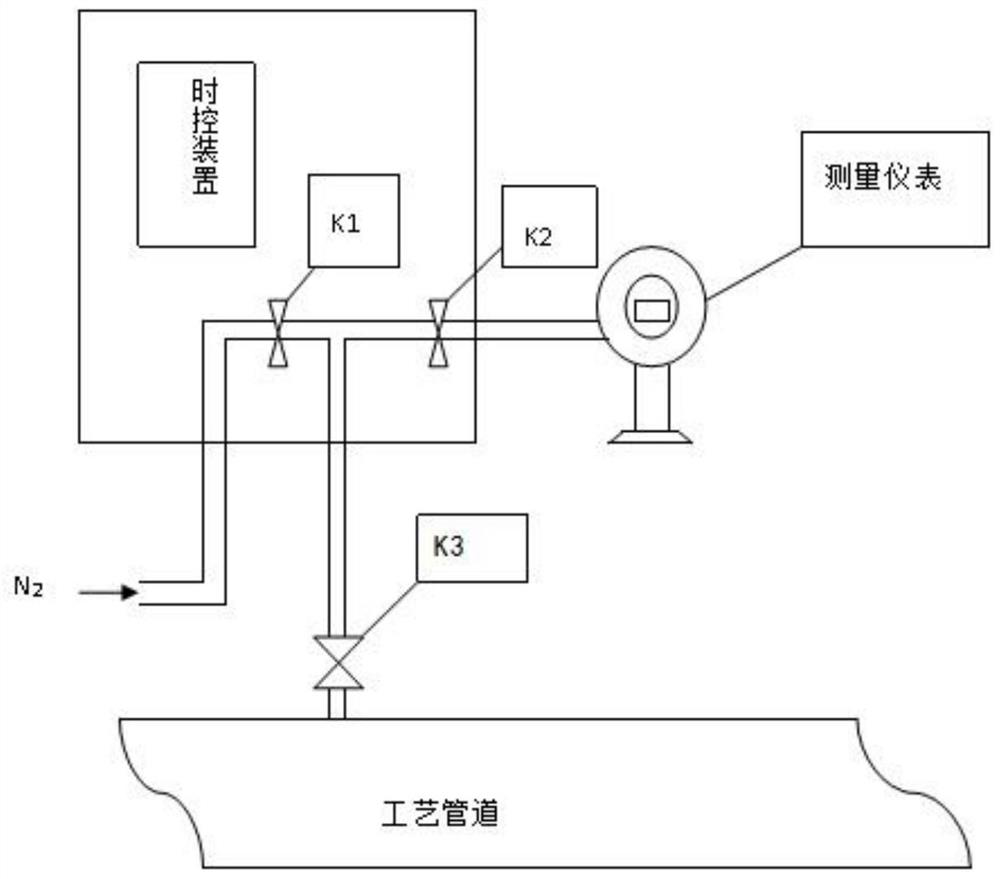

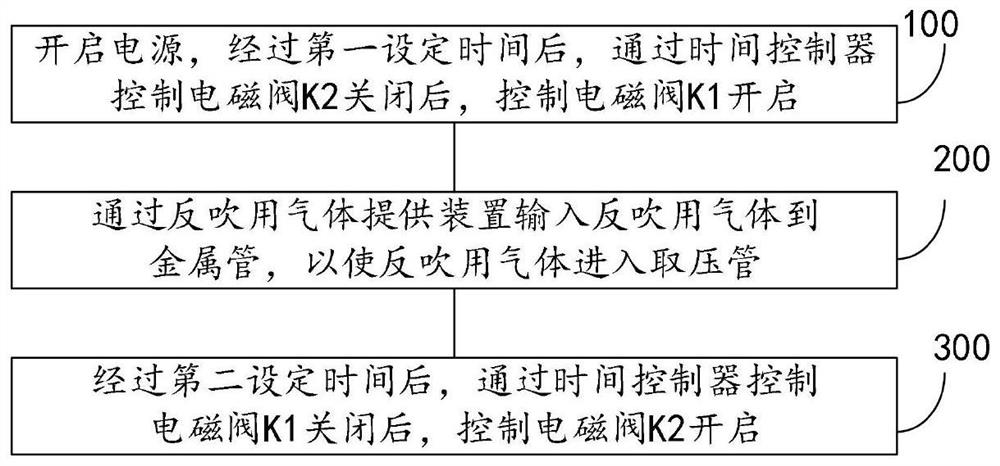

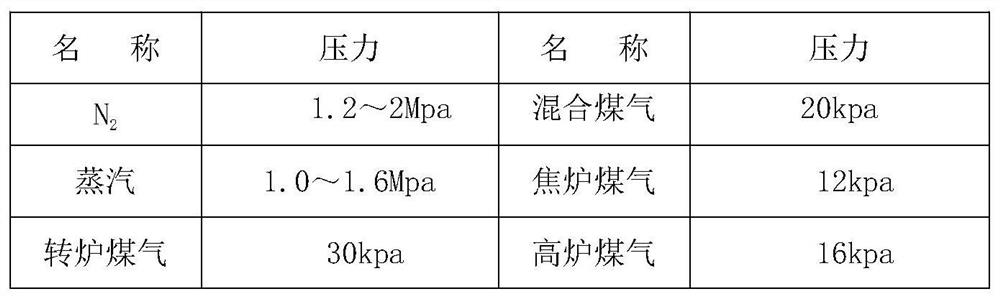

[0033] At present, the use of pressure (source) tubes is very common in the fields of pressure, flow detection, and gas analysis. To measure the pressure on the pipeline, it is generally necessary to install a special pipeline for measuring pressure on the pipeline, that is, to install the pressure tube. However, when the pressure-taking tube is used, the pressure-inducing tube is often blocked, which affects the detection effect, thereby affecting the production efficiency and production quality, and some toxic and harmful gases will cause harm to personnel during the maintenance process, and at the same time cause maintenance costs. After research an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com