Circuit cable wiring ladder

A cable and circuit technology, applied in the field of cable wiring tools, can solve the problems of inconvenient wiring, high risk factor, heavy cable weight, etc., and achieve the effect of reducing waste of resources, reducing risks, and reducing purchase costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

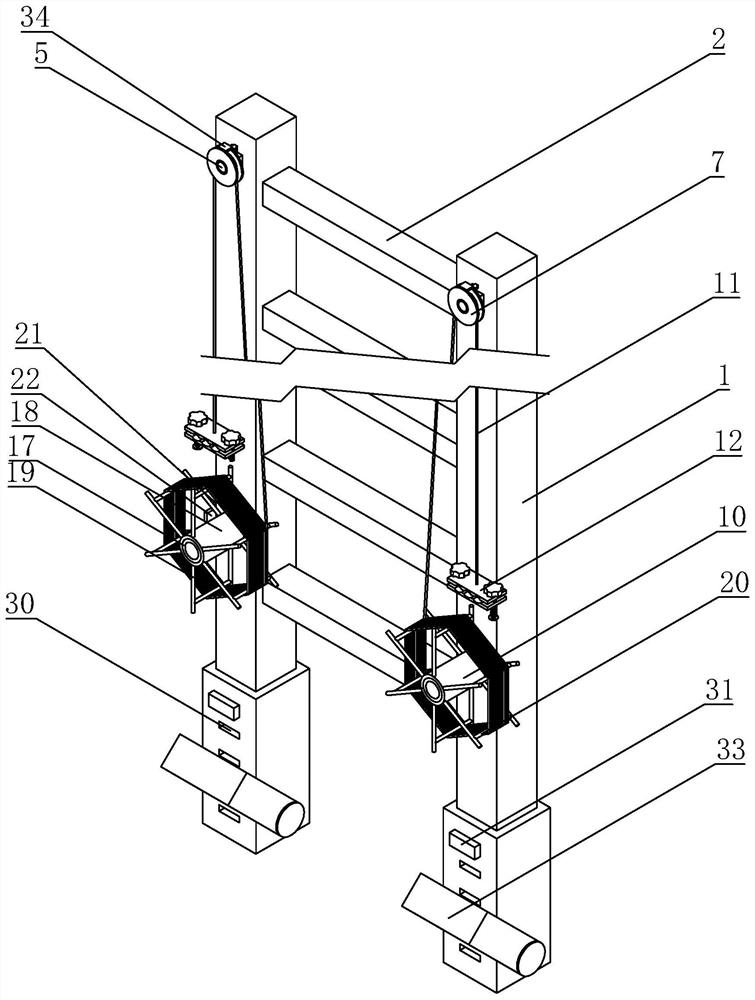

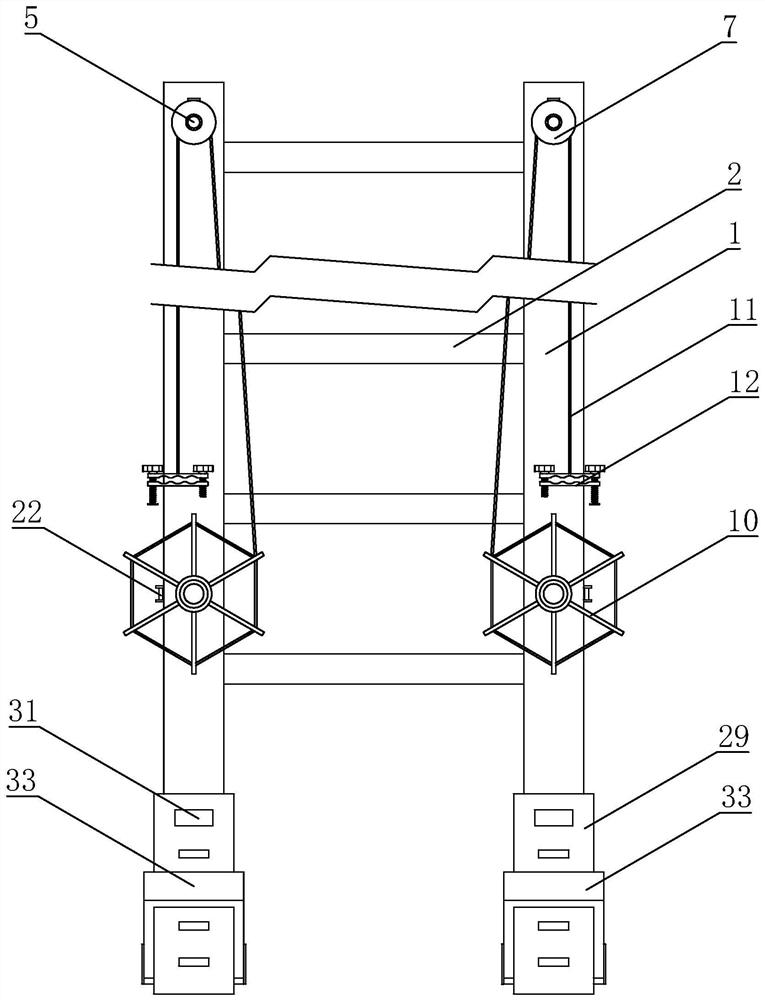

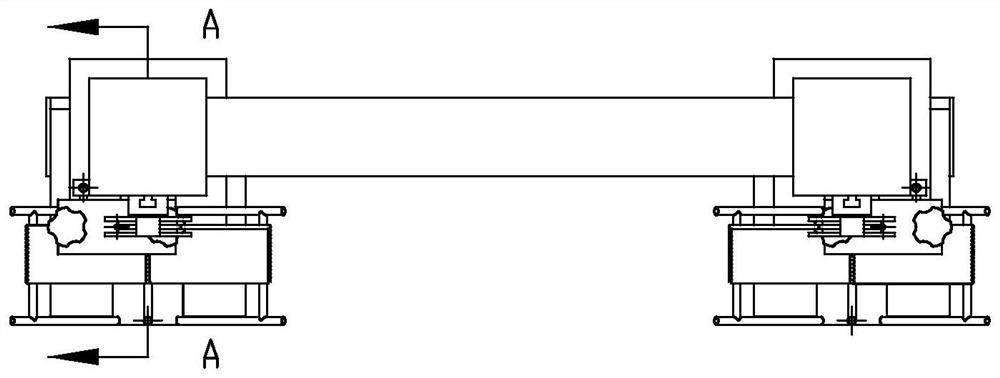

[0039] Embodiment: a circuit cable wiring ladder, including a ladder body, the ladder body includes two vertical bars 1 and a number of beams 2, the upper side of the vertical bar 1 is provided with a first hole 3, the The section of the first hole 3 is rectangular, and the top surface of the first hole 3 is provided with a first T-shaped groove. The first slot 3 is plugged and connected with a first plug 4 matched with it, the top surface of the first plug 4 is provided with a second T-shaped slot 13, and the second T-shaped slot 13 The bottom of the bottom is fixed with a second spring 14, the upper part of the second spring 14 is fixed with a T-shaped block 15, the T-shaped block 15 is matched with the first T-shaped slot, and the T-shaped block 15 is exposed outside the vertical bar 1 The top surface of the part is integrally formed with a hand press plate 16, which is convenient for the staff to press firmly, and the shape block breaks away from the first T-shaped slot wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com