A method for controlling an engine operating mode

A technology of engine operation and control method, which is applied in the direction of engine components, combustion engines, machines/engines, etc., which can solve the problems that fuel consumption cannot be combined with emissions, low-temperature crystallization, and market problems cannot be completely solved, so as to achieve efficient and safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

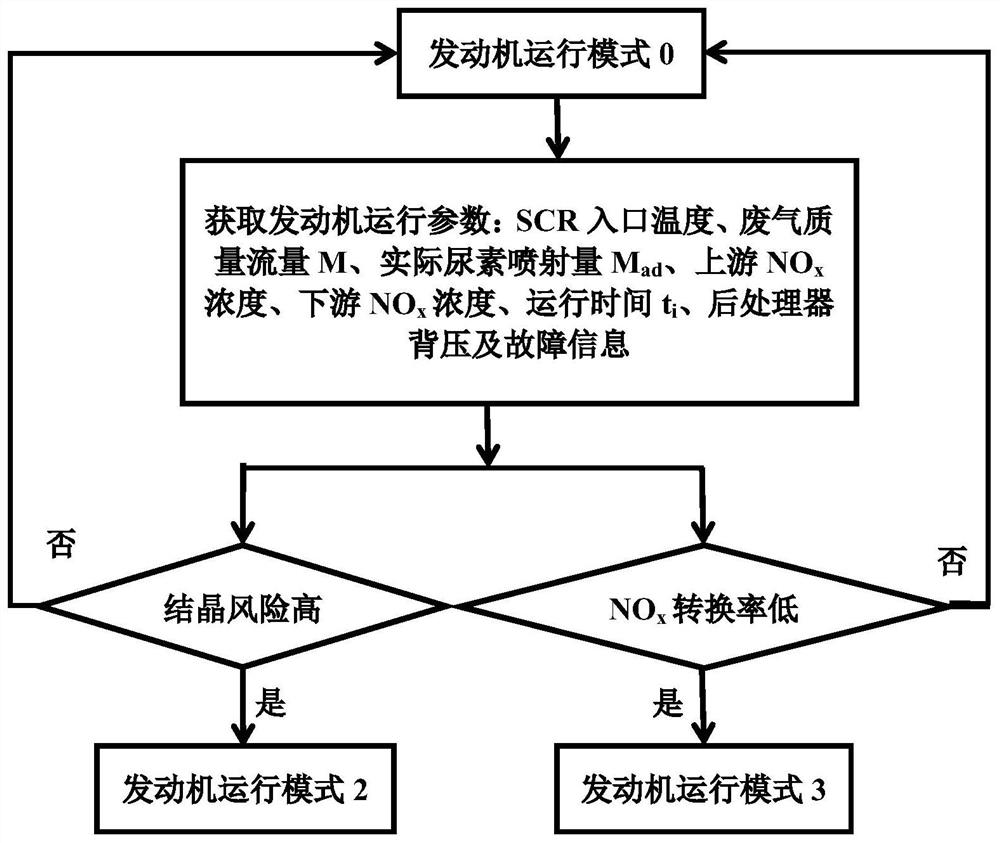

[0053] This embodiment provides a method for controlling the engine operation mode, such as figure 1 As shown, the control method includes:

[0054] Obtaining engine operating parameters, using the parameters to calculate an operating index, comparing the operating index with a preset index, and then selecting a working condition;

[0055] The parameters include SCR inlet temperature, exhaust gas mass flow M, actual urea injection volume M ad , upstream NOx concentration, downstream NO x Concentration, running time t i , post-processor back pressure and fault information;

[0056] The operating indicators include window temperature T i , the urea crystallization factor E corresponding to the window temperature i , NO x Actual removal efficiency η 0 , NO x Theoretical removal efficiency η 1 and engine load rate γ;

[0057] The operating conditions include low crystallization mode of operation or high NO x Conversion rate mode of operation;

[0058] The low crystalli...

Embodiment 2

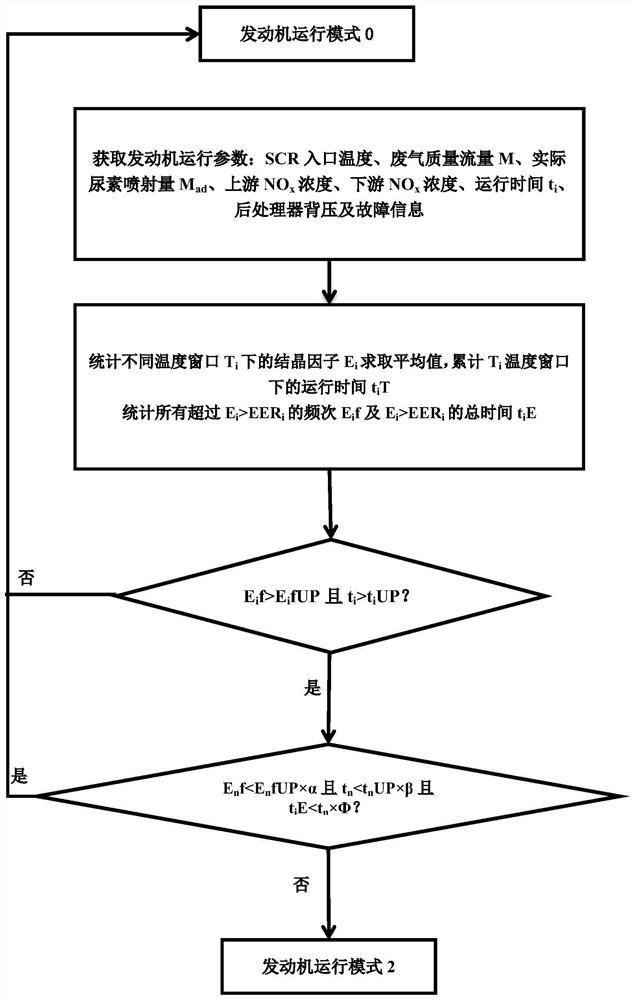

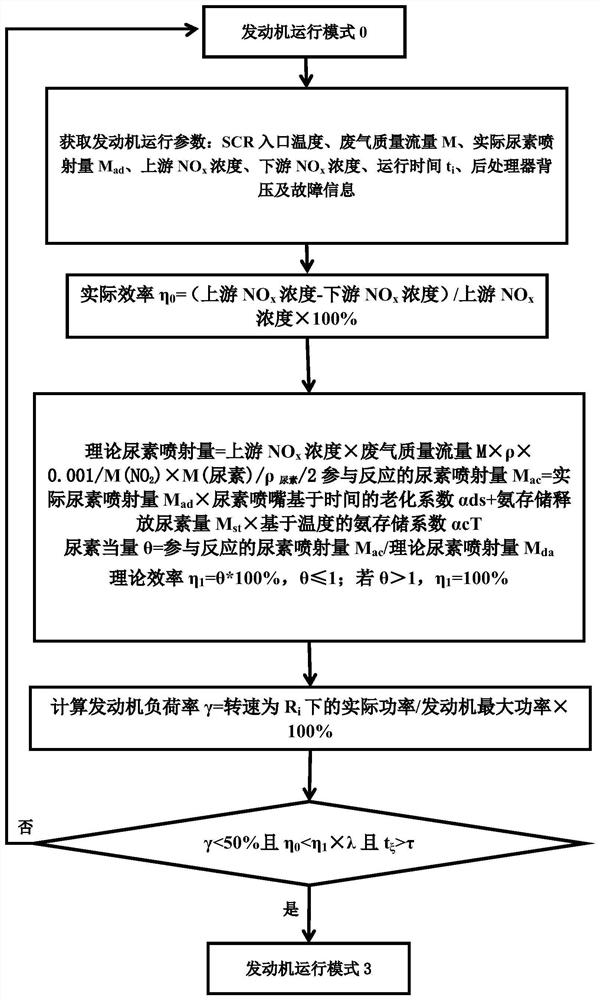

[0061] This embodiment provides a specific control method of the engine operation mode, which can be referred to figure 1 , based on the normal operation mode of the vehicle, real-time monitoring of actual operating parameters, including SCR inlet temperature, exhaust gas flow, urea injection volume, SCR post-treatment upstream NO x value and downstream NO x and carry out risk identification and judgment of urea crystallization according to the operating parameters of the whole vehicle, and switch to engine operation mode 2 if the high risk of crystallization is satisfied; x Conversion efficiency identification and judgment, if the current operating mode is NO x If the conversion efficiency is low, switch to engine operation mode 3; thus solving crystallization and low NO in some special operating conditions x Conversion efficiency issues. The schematic diagram of the comparison of urea crystallization factors in conventional mode is shown in Figure 4 .

[0062] Specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com