A Continuously Adjustable Air Inlet Venting Device

A technology of deflation device and air inlet, which is applied in the direction of jet propulsion device, gas turbine device, machine/engine, etc. It can solve the problems of transmission stability limitation, slow response speed, high-temperature fluid leakage, etc., and achieve continuously adjustable deflation volume , the amount of deflation is avoided, and the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

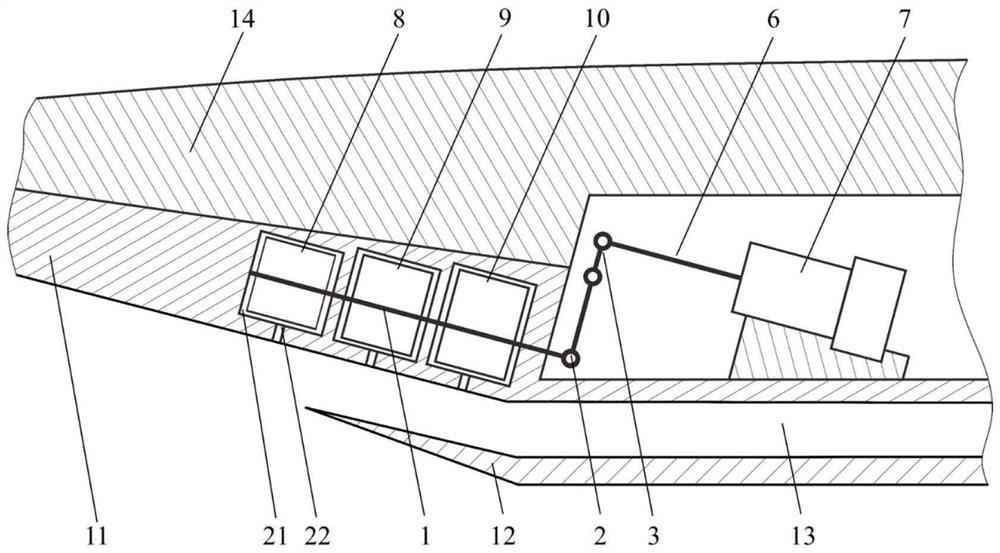

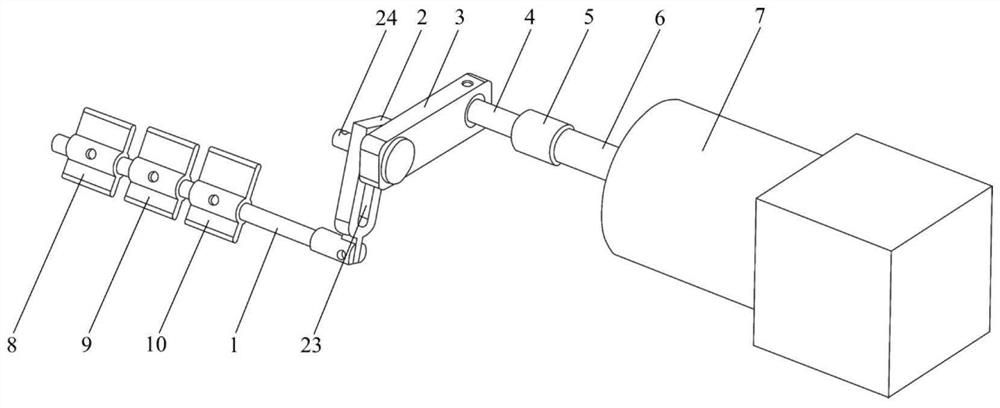

[0020] Please combine figure 1 and figure 2 As shown, the present invention proposes a continuously adjustable air intake deflation device, which includes an air intake precursor 14, a compression surface 11 formed on the outer surface of the precursor, an air intake lip cover 12, and a driving module. An inner chamber 20 is provided in the air intake precursor body, and several air release grooves 21 located inside the compression surface are also provided in the air inlet precursor body, and both sides of the air release grooves 21 communicate with the outside of the air intake channel. An opening 22 passing through the compression surface is provided between the air release groove 21 and the compression surface 11 , and the opening 22 communicates with the air release groove 21 .

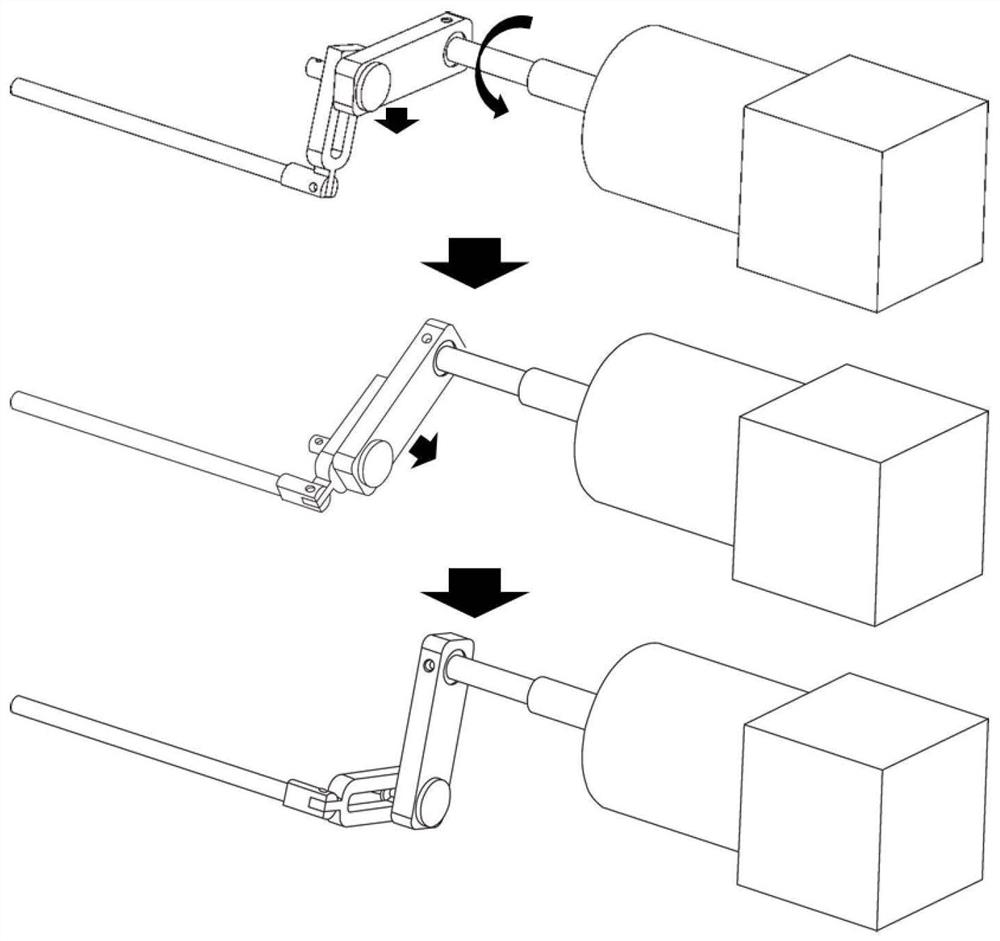

[0021] The drive module includes a motor 7 located in the inner cavity, blades 8, 9, 10 located in the air release groove 21, an output shaft 1 connected to the blades and driving the blades to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com