Sampling equipment of bioreactor

A bioreactor and sampling equipment technology, applied in the direction of sampling devices, etc., can solve the problems of raw material sinking, increased risk of bacterial contamination, easy stratification, etc., and achieve the effect of rapid discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

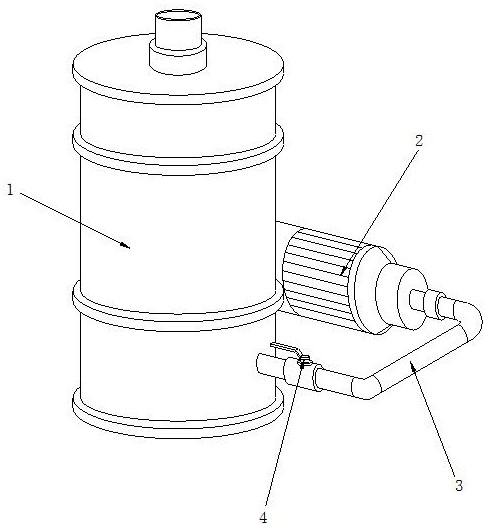

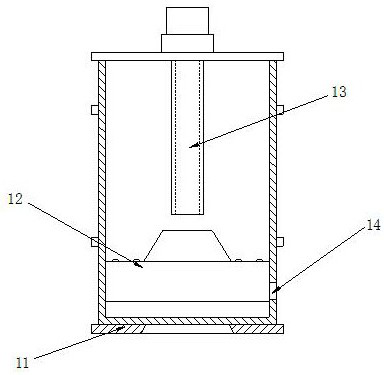

[0028] as attached figure 1 To attach Figure 7 Shown:

[0029] The present invention provides a sampling device for a bioreactor, the structure of which includes: a sampling bottle 1, a water pump 2, a connecting pipe 3, and a switch 4. The inner side of the sampling bottle 1 is embedded and connected to the outer ring of the connecting pipe 3, The inner ring of the water pump 2 is nestedly connected with the outer ring of the connecting pipe 3 , and the outer ring of the connecting pipe 3 is provided with a switch 4 .

[0030] Wherein, the sampling bottle 1 includes a base 11, a connecting area 12, a drain pipe 13, and a water outlet 14, the upper end surface of the base 11 is welded to the lower end surface of the sampling bottle 1, and the connecting area 12 is installed on the bottom surface of the sampling bottle 1. Inside, the outer ring of the drain pipe 13 is nested with the inner ring of the sampling bottle 1 , and the water outlet 14 and the sampling bottle 1 are...

Embodiment 2

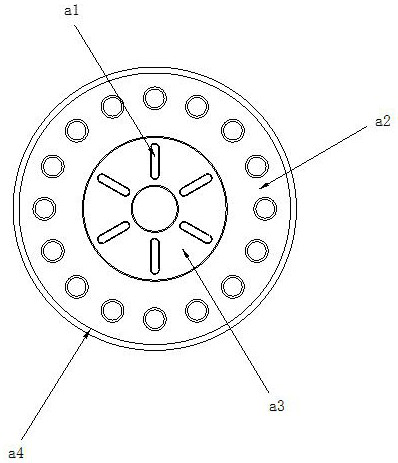

[0039] as attached Figure 8 to attach Figure 9 Shown:

[0040] The present invention provides a sampling device for a bioreactor. The swing block d2 includes a through hole h1, a housing h2, and a moving device h3. The through hole h1 and the housing h2 are an integrated mechanism. The moving device h3 One side is fixedly connected to the inner side of the through hole h1, and the through holes h1 are evenly distributed on the housing h2, and each through hole h1 is provided with a moving device h3, which can effectively discharge the liquid.

[0041] Wherein, the moving device h3 includes a moving rod j1, an airbag j2, an elastic ball j3, and a cavity j4, one side of the moving rod j1 is slidably connected to the inner side of the cavity j4, and the airbag j2 is installed in the cavity j4 The inner side of the elastic ball j3 is slidingly connected to the inner side of the cavity j4, the outer ring of the elastic ball j3 is fixedly connected to the moving rod j1, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com