Center exhaust device of stirring shaft of fermentation tank

A technology of exhaust device and stirring device, which is applied in bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical cleaning device, etc. Bacteria dead angle, shaft seal rupture and other problems, to achieve the effect of reducing the probability of contamination and good sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

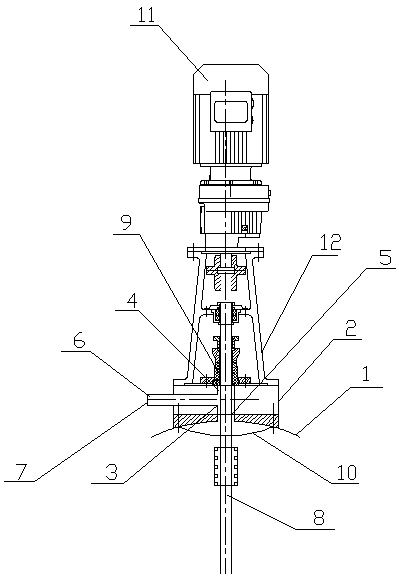

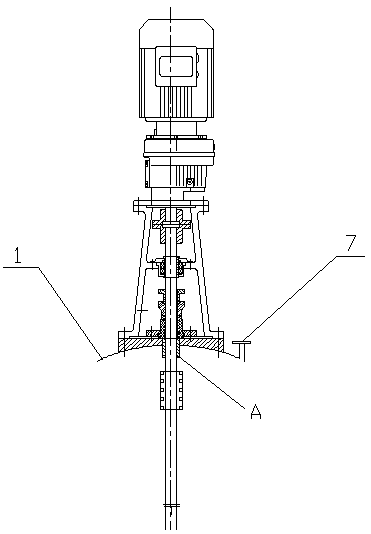

[0017] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on the specific embodiments and in conjunction with the accompanying drawings.

[0018] This embodiment provides a stirring shaft 8 exhaust device, such as figure 1 As shown, it includes a fermenter 1 and a stirring device. The stirring device includes a stirring motor 11 , a stirring shaft 8 driven by the stirring motor 11 , and a stirring frame 12 for erecting the stirring motor 11 on the fermenter 1 .

[0019] A joint 2 is fixedly arranged on the upper end of the fermenter 1 , and the stirrer frame 12 is fixedly connected to the joint 2 . A cavity is opened in the middle of the joint 2, and a T-shaped three-way pipe fitting 3 is installed in the cavity. The interface 4 and the second interface 5 are on the same vertical line, the first interface 4 communicates with the upper end of the joint 2, the second interface 5 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com