A Smart Factory Control System

A factory control and intelligent technology, applied in the direction of comprehensive factory control, general control system, control/adjustment system, etc., can solve the problems of insufficient refined lighting of the lighting system, difficulty in observing whether the road surface is abnormal, power consumption of enterprise lighting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

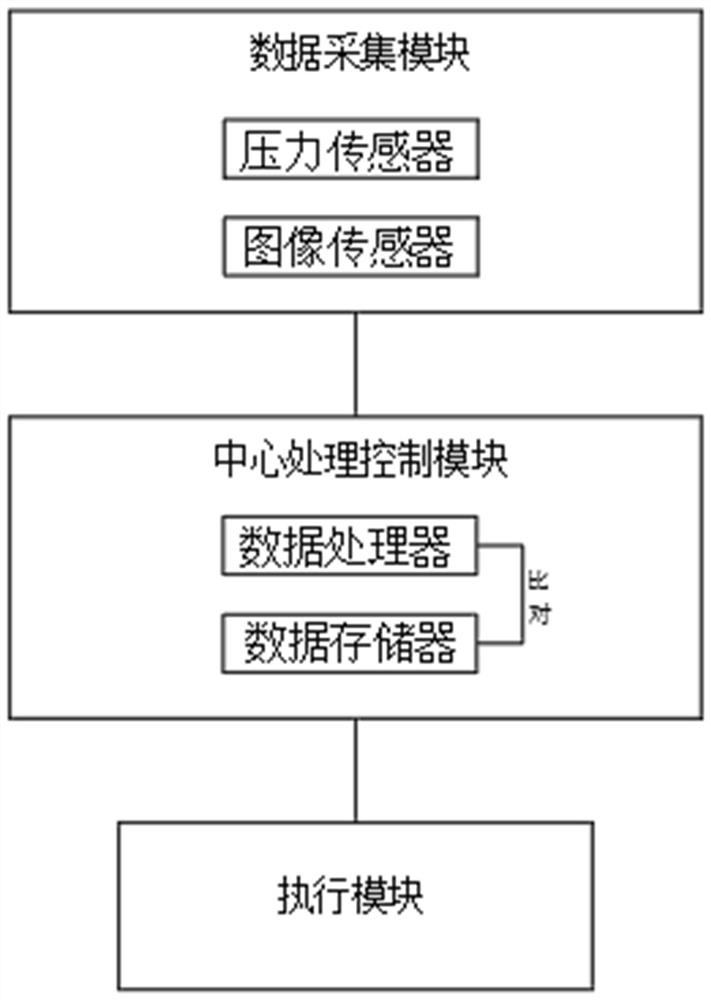

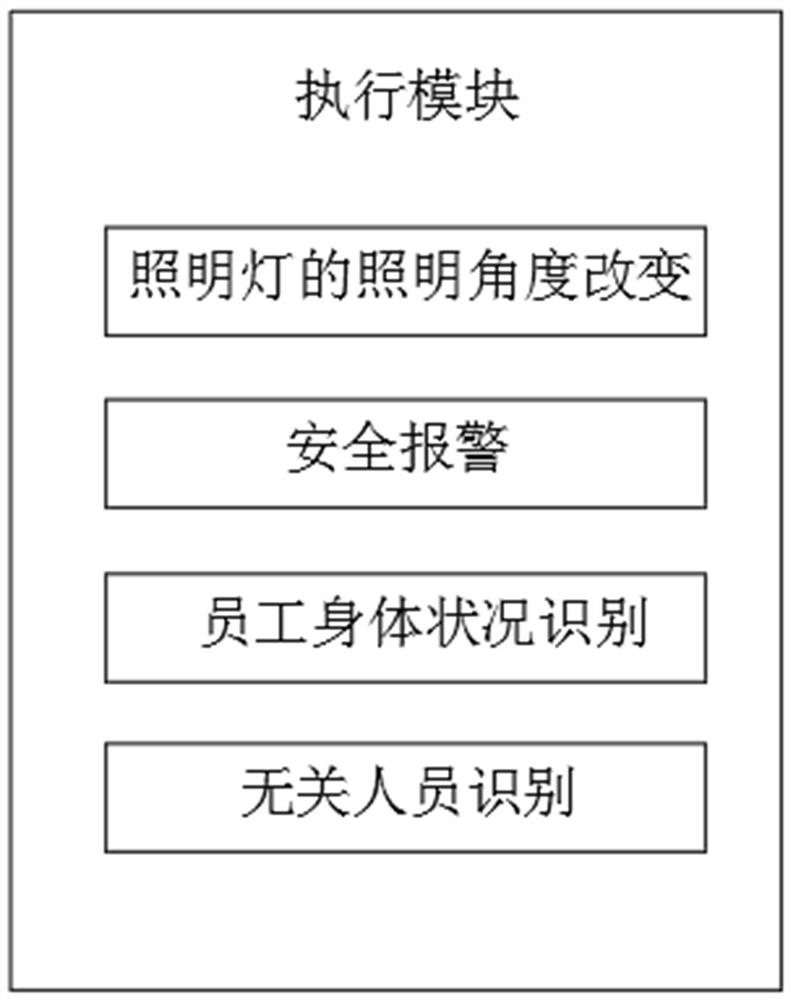

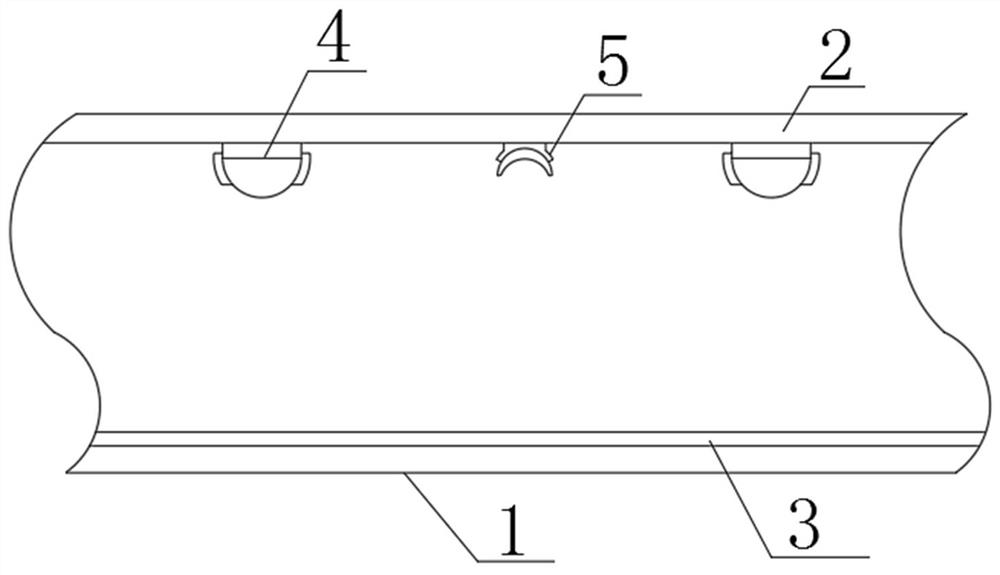

[0031] Such as Figure 1-5 As shown, a smart factory control system includes a data acquisition module for collecting data, a central processing control module for processing data, and an execution module that responds to the collected data. The data acquisition module includes a pressure sensor (3) And the image sensor (8), the pressure sensor (3) is used to collect the data of the weight of people and goods and the contact area with the ground (1), and the image sensor (8) is used to identify the shadow length changes of people and goods during the movement process Data, the central processing control module includes a data processor (17) and a data storage (18), the data processor (17) is used to process the data collected by the pressure sensor (3) and the image sensor (8), and the data storage (18) It is used to store the basic body data of the person and the information previously processed by the data processor (17), and the data processed by the data processor (17) is ...

Embodiment 2

[0040] Such as Figure 1-5 As shown, a smart factory control system includes a data acquisition module for collecting data, a central processing control module for processing data, and an execution module that responds to the collected data. The data acquisition module includes a pressure sensor (3) And the image sensor (8), the pressure sensor (3) is used to collect the data of the weight of people and goods and the contact area with the ground (1), and the image sensor (8) is used to identify the shadow length changes of people and goods during the movement process Data, the central processing control module includes a data processor (17) and a data storage (18), the data processor (17) is used to process the data collected by the pressure sensor (3) and the image sensor (8), and the data storage (18) It is used to store the basic body data of the person and the information previously processed by the data processor (17), and the data processed by the data processor (17) is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com