Relay and parameter correction method of relay

A relay and integrated technology, applied in the field of relay parameter correction and electromagnetic relay, to achieve the effect of high adjustment efficiency and low manufacturing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

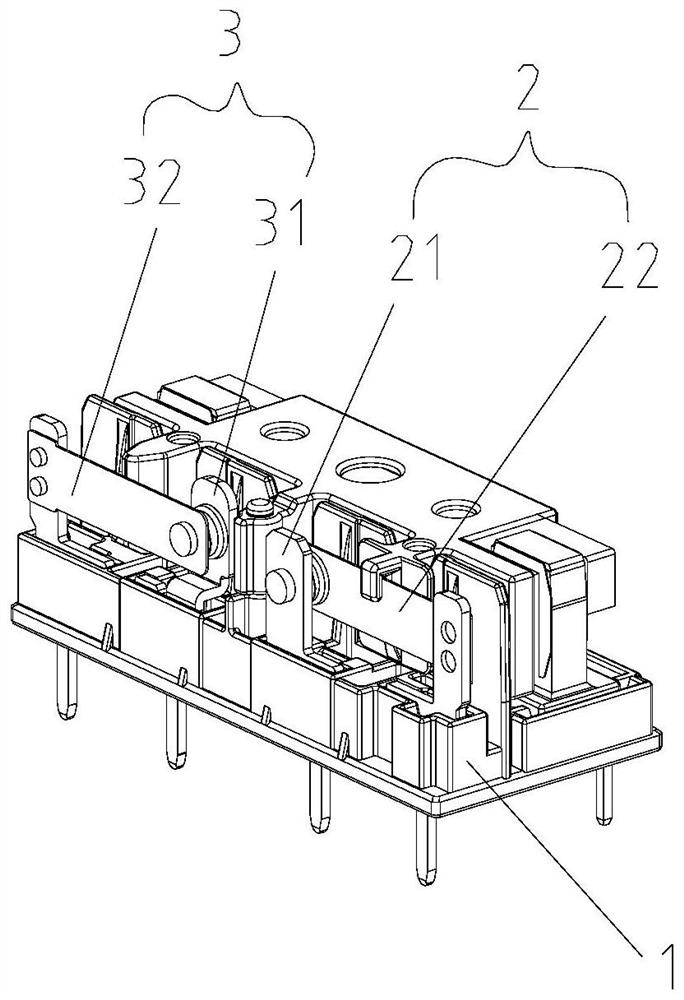

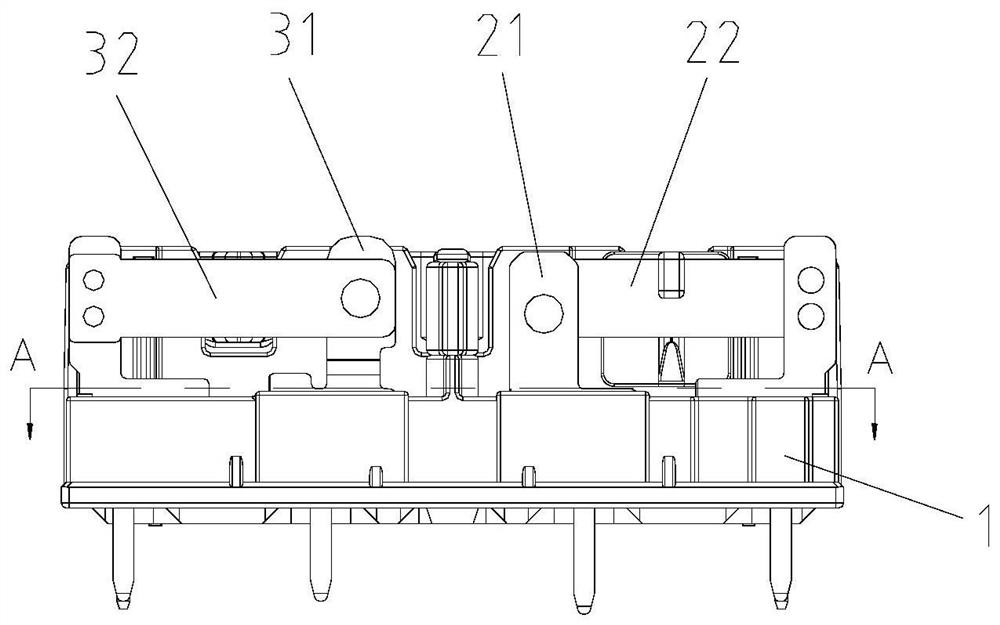

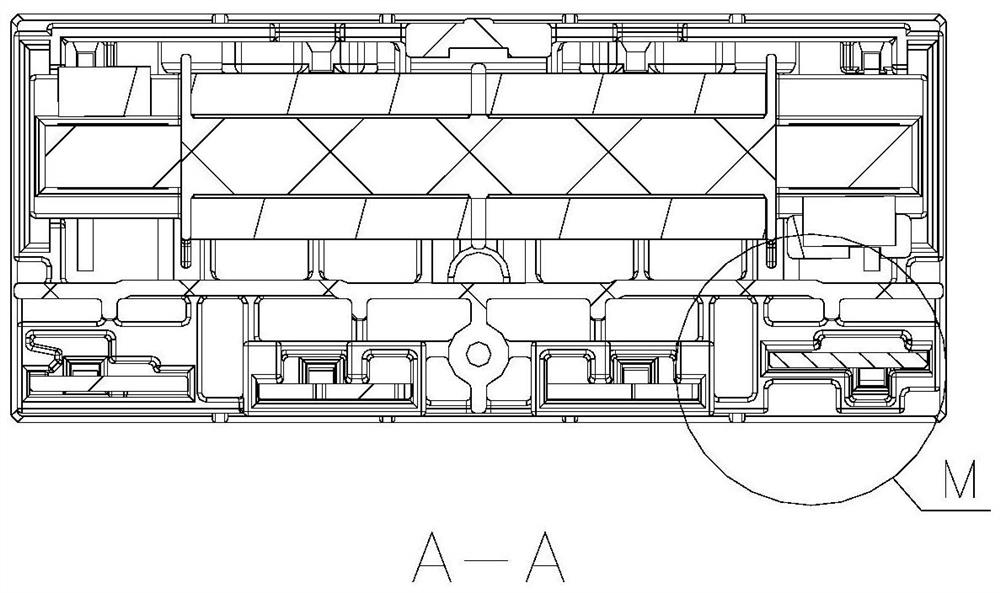

[0046] Such as figure 1As shown, this embodiment provides a relay, including a base 1, a contact assembly and an electromagnetic actuation assembly mounted on the base 1, wherein the contact assembly includes a first reed set 2 and a second reed set 3. It is used to control the on-off of the two circuits respectively. The first reed group 2 includes the first static reed 21 and the first moving reed 22 arranged at intervals, and the second reed group 3 includes the second static reeds arranged at intervals. Reed 31 and the second movable reed 32, the first static reed 21 is oppositely arranged on the outer side of one end of the first movable reed 22, and the second static reed 31 is oppositely arranged on the outer side of one end of the second movable reed 32 position, the first static reed 21, the first moving reed 22, the second static reed 31 and the second moving reed 32 all have conductive contacts, and the electromagnetic actuation assembly (usually including coil, yok...

Embodiment 2

[0056] Such as Figure 11 As shown, this embodiment provides a relay, including a base 4, a contact assembly and an electromagnetic actuation assembly installed on the base 4, wherein the contact assembly includes a static reed 5 and a movable reed 6 arranged at intervals , both the static reed 5 and the movable reed 6 have conductive contacts, driven by the electromagnetic actuation assembly, the movable reed 6 can establish contact or separation of the conductive contacts with the static reed 5, thereby realizing the conduction of the circuit on or off.

[0057] Different from Embodiment 1, the static reed 5 and the moving reed 6 in this embodiment are relatively upright and arranged side by side, and both the static reed 5 and the moving reed 6 are fixedly inserted on the base 4, Such as Figure 14-15 The base 4 is provided with a first insertion card slot 41 and a second insertion card slot 42, and the static reed 5 and the moving reed 6 are inserted and fixed in the fir...

Embodiment 3

[0064] This embodiment proposes a parameter calibration method for a relay, including the following steps:

[0065] A. Provide a set relay, the relay may be the relay of Embodiment 1 and Embodiment 2 above or other modified embodiments equivalent to the structural principle of the two.

[0066] B. Change the convex height of the convex hull on either side or both sides of the two sheet surfaces on the reed that needs to be adjusted (that is, adjust the convex hull adjustment structure), so that the reed produces a positive or negative angle compared to the original The swing deflection until the distance and angle between the conductive contact on the reed to be adjusted and another conductive contact meets the mechanical or electrical parameter requirements; this step B can be performed on the production line to achieve rapid real-time adjustment.

[0067] C, Insert the assembly reed into the insertion card slot of the base.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com