Linear motor adjusting structure for track system

A linear motor and structure adjustment technology, which is applied in the field of rail transit, can solve the problems of high processing difficulty, high processing cost, high installation and debugging cost, and difficulty in ensuring accuracy, and achieve small deformation, reduce installation and use costs and later labor costs, The effect of lowering the altitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

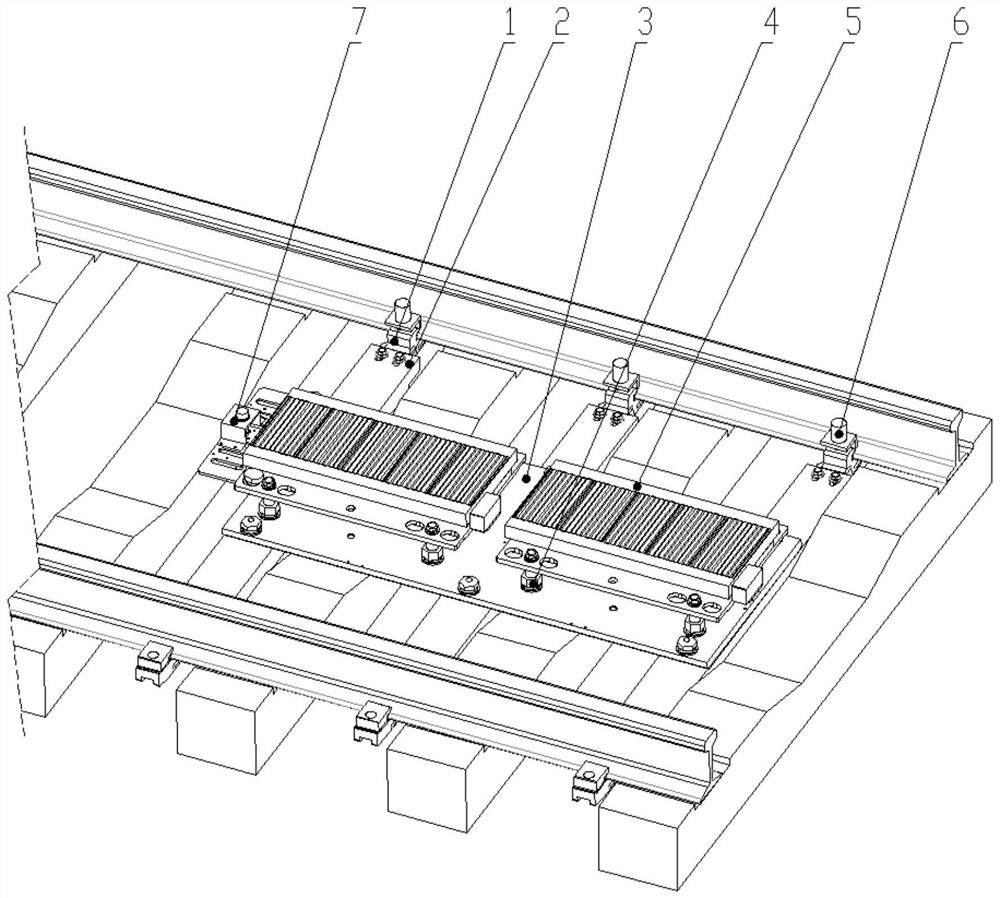

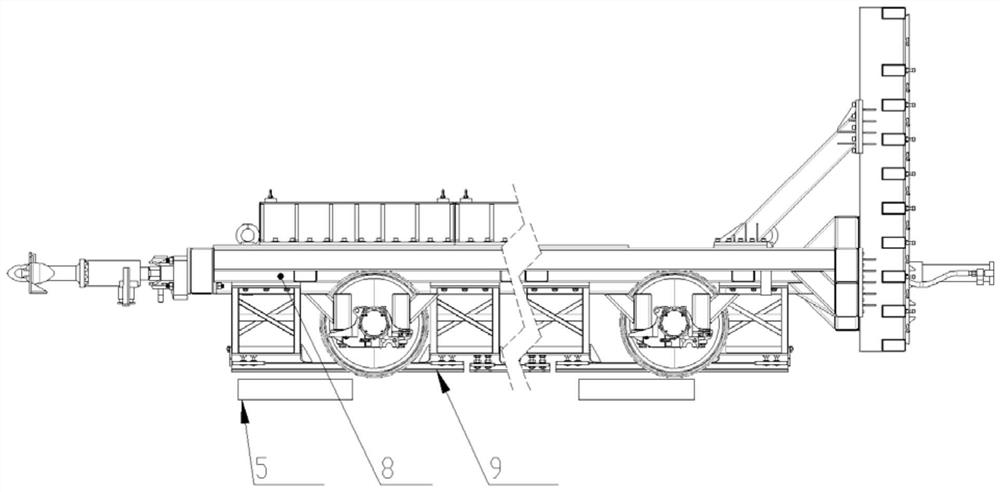

[0017] Specific implementation mode one: combine Figure 1-Figure 2 Describe this embodiment, the linear motor adjustment structure for the track system, which includes a support frame, a mounting plate 3, a position sensor 7, two linear motors 5, a plurality of height detection sensors 6 and a plurality of electric push rods 4; the mounting plate 3 is installed on the bottom end of the track through a support frame, and two linear motors 5 are installed on the mounting plate 3 along the length direction, and each linear motor 5 is mounted on the mounting plate 3 through a plurality of electric push rods 4, and the A height detection sensor 6 is installed on the support frame along the length direction, and the position sensor 7 is installed on the linear motor 5 on the side where the track is the entry end.

[0018] The electric push rod 4, the linear motor 5, the height detection sensor 6 and the position sensor 7 are connected to the external PLC controller, and the height ...

specific Embodiment approach 2

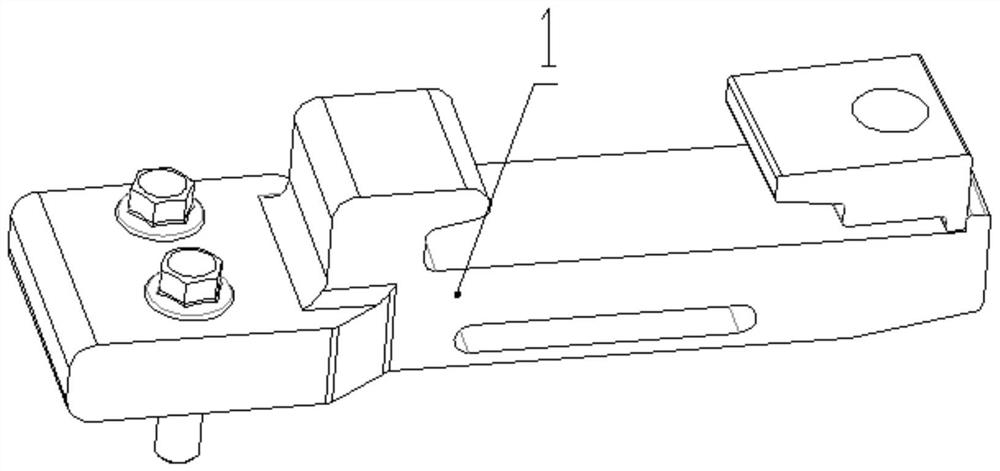

[0019] Specific implementation mode two: combination Figure 1-Figure 2 Describe this embodiment, a linear motor adjustment structure for a track system described in this embodiment, the support frame includes a plurality of connecting plates 2 and a plurality of track clamps 1; two ends of each connecting plate 2 are respectively installed with a track The clamp 1 and the connecting plate 2 are installed on the track through two track clamps 1 . Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0020] Specific implementation mode three: combination Figure 1-Figure 2 Describe this embodiment, a linear motor adjustment structure for a rail system described in this embodiment, the rail clamp 1 includes a fixed block, a fixed block and a movable block; the fixed block is installed on the fixed block, and the movable block passes through The bolts are fixedly installed on the fixed block, and the fixed block and the movable block are relatively arranged and installed on the bottom end of the rail, and each fixed block is fixedly installed on one end of the connecting plate 2 by bolts. Other compositions and connection methods are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com